All cotton digital printing textile slurry and preparation method thereof

A digital printing and textile size technology, applied in the field of textile size, can solve problems such as difficulty in sizing, poor fluidity, and unsatisfactory effects, and achieve the effects of good color fastness, good color reproduction, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

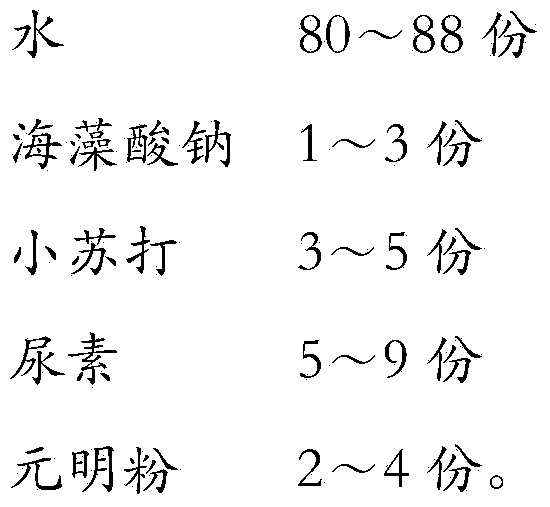

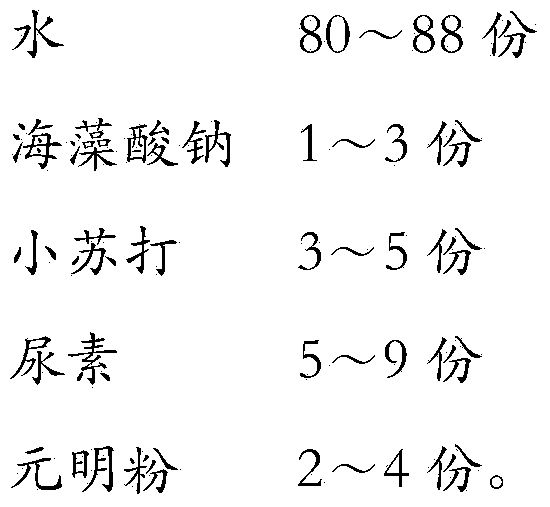

Method used

Image

Examples

Embodiment 1

[0019] The condition is at normal temperature, and the stirring speed is 800 rpm, including the following steps: in parts by weight, first take 80 parts of water, add 3 parts of sodium alginate, mix and stir for 10 minutes, then add 9 parts of urea, and continue mixing Stir for 10 minutes, add 3 parts of Yuanming powder, mix and stir for 4 hours, finally add 5 parts of baking soda, mix and stir for 2 hours, and let it stand.

Embodiment 2

[0021] The condition is at normal temperature, and the stirring speed is 1000 rpm, including the following steps: in parts by weight, first take 88 parts of water, add 1 part of sodium alginate, mix and stir for 5 minutes, then add 6 parts of urea, and continue mixing Stir for 5 minutes, add 2 parts of Yuanming powder, mix and stir for 5 hours, finally add 3 parts of baking soda, mix and stir for 2 hours, and let it stand.

Embodiment 3

[0023] The condition is at normal temperature, and the stirring speed is 900 rpm, including the following steps: in parts by weight, first take 85 parts of water, add 2 parts of sodium alginate, mix and stir for 10 minutes, then add 6 parts of urea, and continue mixing Stir for 10 minutes, add 3 parts of Yuanming powder, mix and stir for 4 hours, finally add 4 parts of baking soda, mix and stir for 2 hours, and let it stand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com