Front wheel driving control system and method of rubber-tyred paver and rubber-tyred paver

A front-wheel drive and control system technology, applied in control/regulation systems, non-electric variable control, mechanical pressure/force control, etc., can solve rear wheel slippage, decrease in machine load capacity, and friction coefficient between rear wheels and the ground No other problems, to achieve the effect of increasing the auxiliary driving torque of the front wheels and enhancing the working performance of the machine with load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

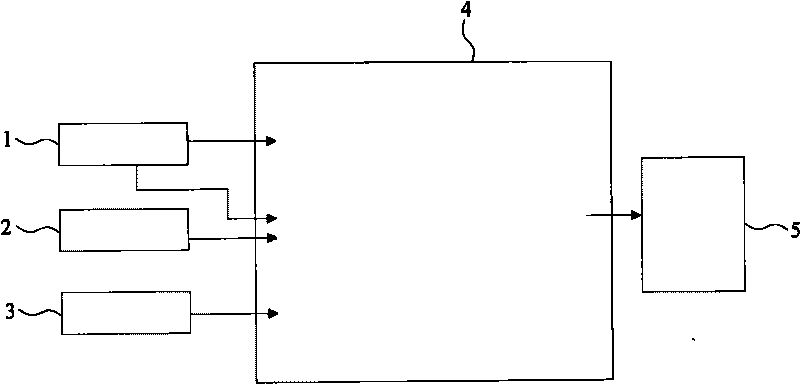

[0029] exist figure 1 A schematic diagram of a front-wheel drive control system for anti-skid of a tire-type paver is shown in . The control system is composed of a speed sensor 1 , a steering angle sensor 2 , a pressure sensor 3 , a control device 4 and a front wheel drive hydraulic circuit 5 of the paver.

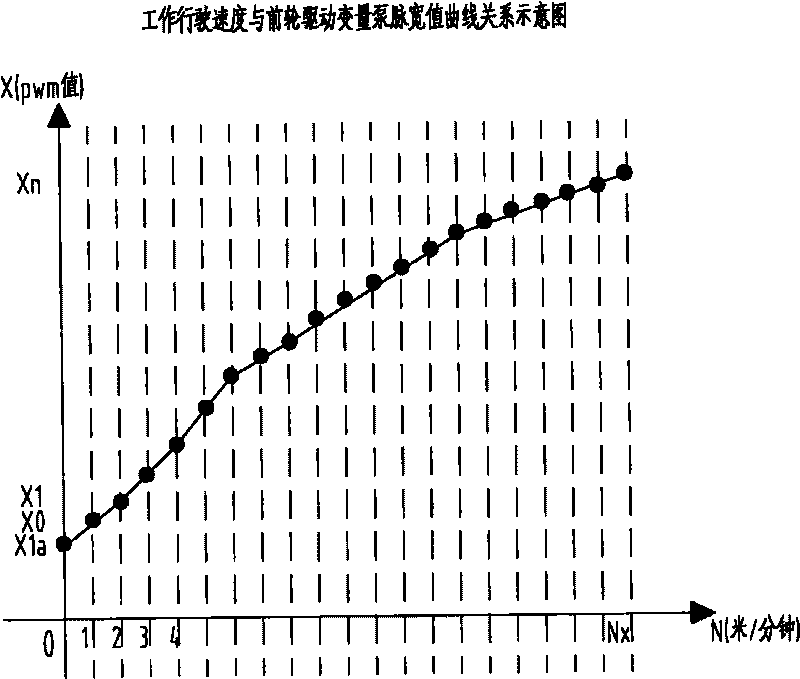

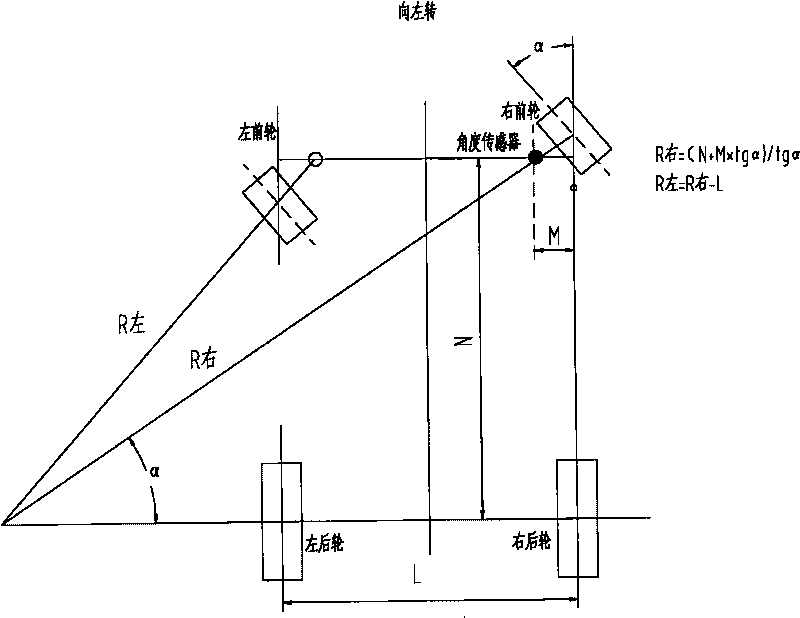

[0030] Such as figure 1 As shown, through the speed sensor 1, the steering angle sensor 2, and the pressure sensor 3, the working walking speed signal, steering angle signal, and load pressure signal of the tire-type paver are collected in real time and sent to the control device 4. The schematic diagram of the relationship curve between the speed and the working speed and the front-wheel drive variable pump pulse width value is obtained to obtain the pre-output pulse width value X1; the steering radius of the left and right wheels is calculated according to the obtained steering angle signal, and the ratio of the left and right working speed to the steering radius ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com