Main transmission device of double-needle warp knitting machine

A technology of warp knitting machine and main drive, applied in the direction of transmission device, flat warp knitting machine, warp knitting, etc., can solve the problems that the main shaft cannot be rotated synchronously and reliably, inconvenient to use, and the structure of the warp knitting machine is complex, etc. Ensure strict synchronization, ensure normal operation, and facilitate disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

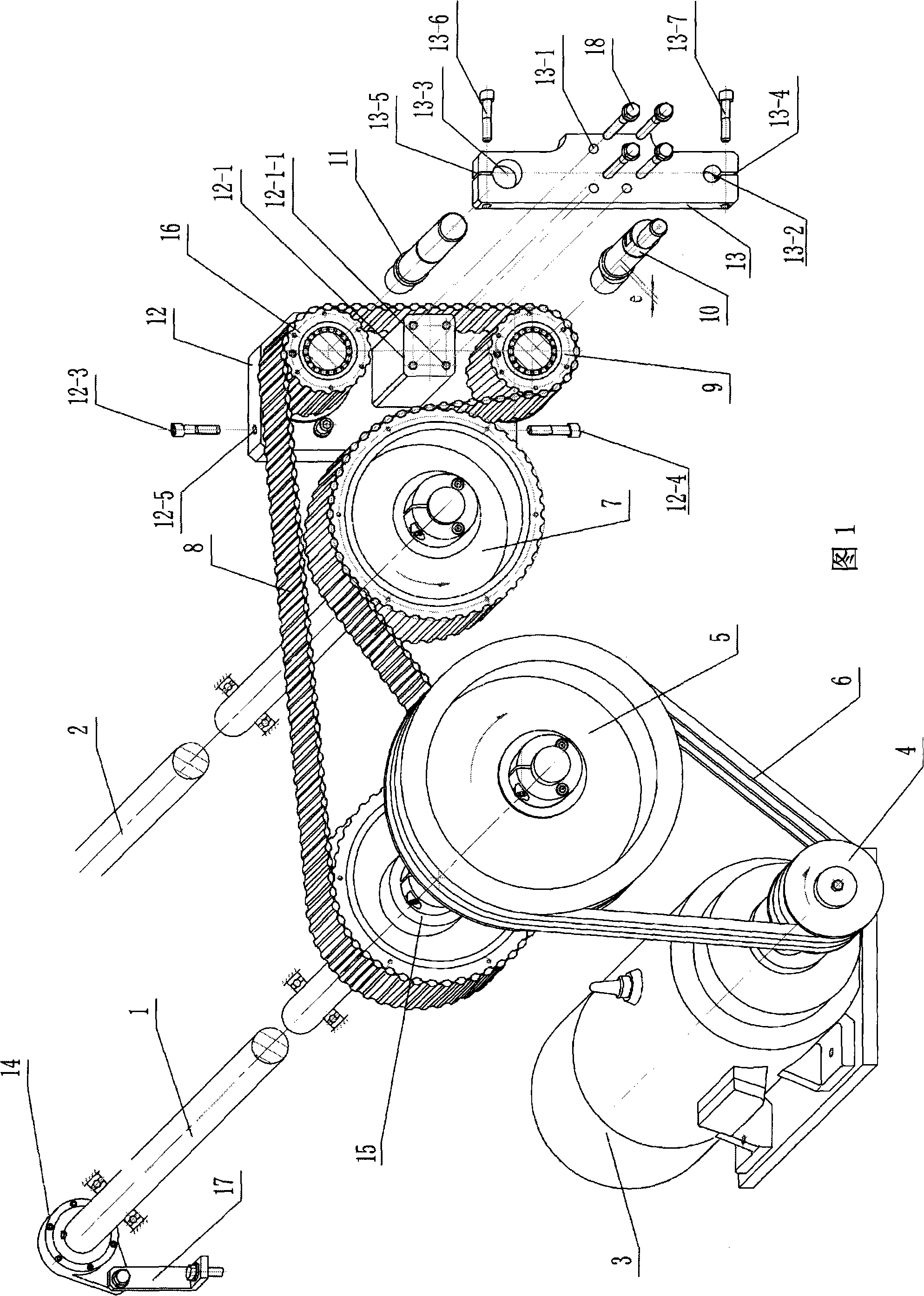

[0025] See Fig. 1, the main transmission device of the double-needle warp knitting machine of the present embodiment comprises: first main shaft 1, second main shaft 2, motor 3, the small belt pulley 4 that is fixed on the output shaft of motor 3, is fixed on the first main shaft 1 Large pulley 5 on the front end head, the first synchronous pulley 15, the second synchronous pulley 7, guide shaft holder 12, upper guide wheel 16, lower guide wheel 9, upper guide shaft 11, lower guide shaft 10, double Surface synchronous belt 8, connecting block 12-1, front end plate 13, first clamping bolt 13-6, second clamping bolt 13-7, one-way clutch 14, mounting bolt 18 and frequency conversion circuit.

[0026] Both the first main shaft 1 and the second main shaft 2 are supported on the frame through bearings, the first main shaft 1 and the second main shaft 2 are arranged parallel to the same height, and the second main shaft 2 is located on the right side of the first main shaft 1; The be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com