Test device for simulating tunnel excavation process

A technology of tunnel excavation and test device, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of difficult excavation, difficult collection, insufficient mold accuracy, etc., and achieves convenient disassembly, accurate and reliable test data, and contour. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

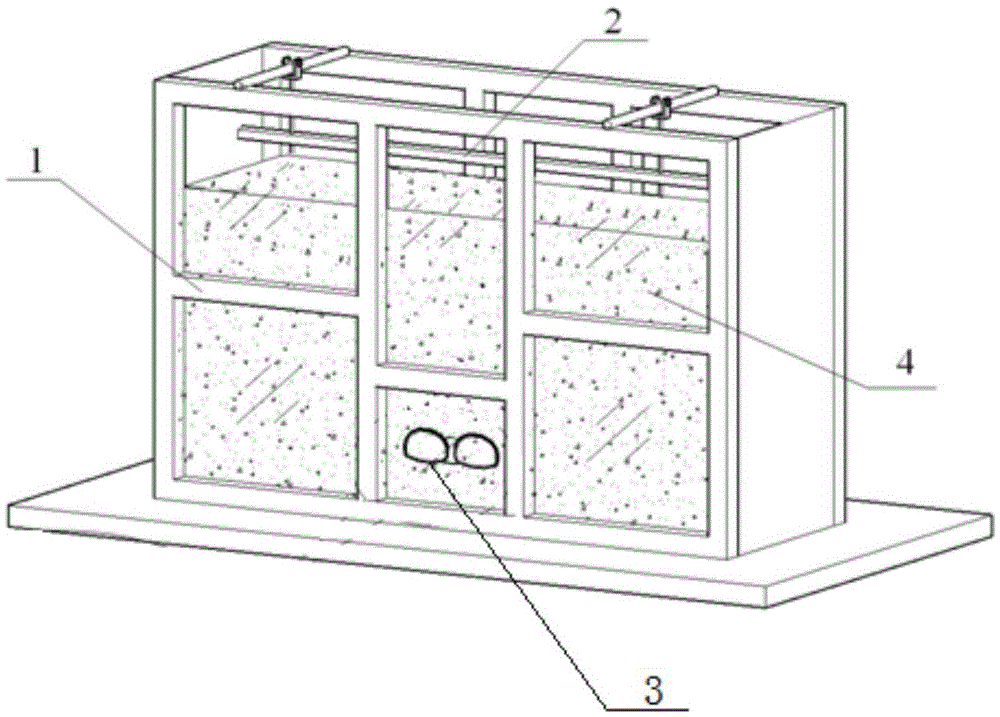

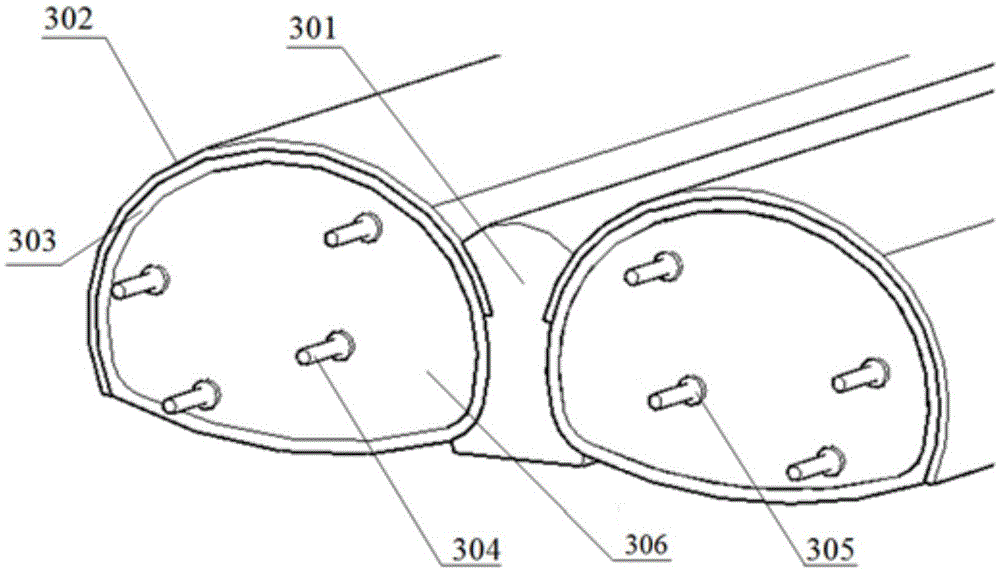

[0067] Taking the excavation simulation of a multi-arch tunnel as an example, the single tunnel span is 9m and the tunnel height is 7m. The initial support of the prototype tunnel is 30cm, the secondary lining is 40cm, the middle partition wall is 150m thick, the surrounding rock grade of the tunnel construction area is grade IV, the tunnel burial depth is 60m, and the excavation footage of the tunnel is 3m / cycle.

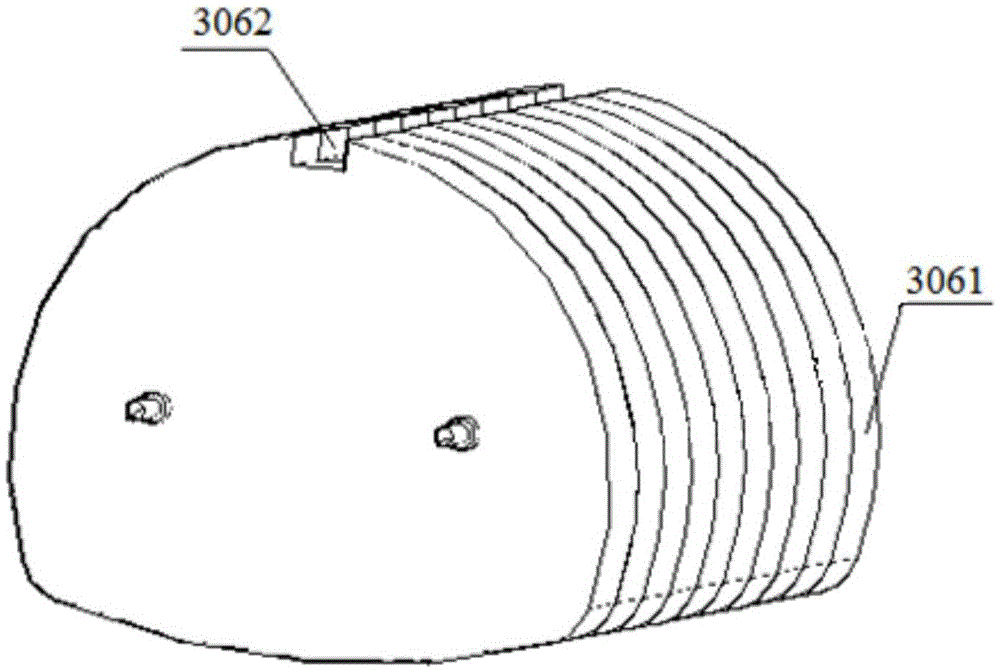

[0068] The similarity ratio is 50, the single hole span of the model tunnel is 18cm, the height is 14cm, the thickness of the initial support simulation layer 302 of the primary support is 6mm, the thickness of the secondary lining simulation layer 303 is 8mm, and the thickness of the middle partition wall test body 301 is 30mm, and the embedding depth of the soil simulation material 4 above the pre-embedded body 3 is 1.2m.

[0069] 1. Sculpture model making mold and excavation and pre-embedded parts:

[0070] In CAD, according to the model size and shape, draw th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com