Automatic leveling system for vehicle body platform

An automatic leveling and platform technology, which is applied in the field of leveling system, can solve the problems of heavy objects slipping, tipping, real-time adjustment, etc., and achieve the effect of avoiding oscillation, ensuring stability, and ensuring levelness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation and working principle of the body platform automatic leveling system proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments .

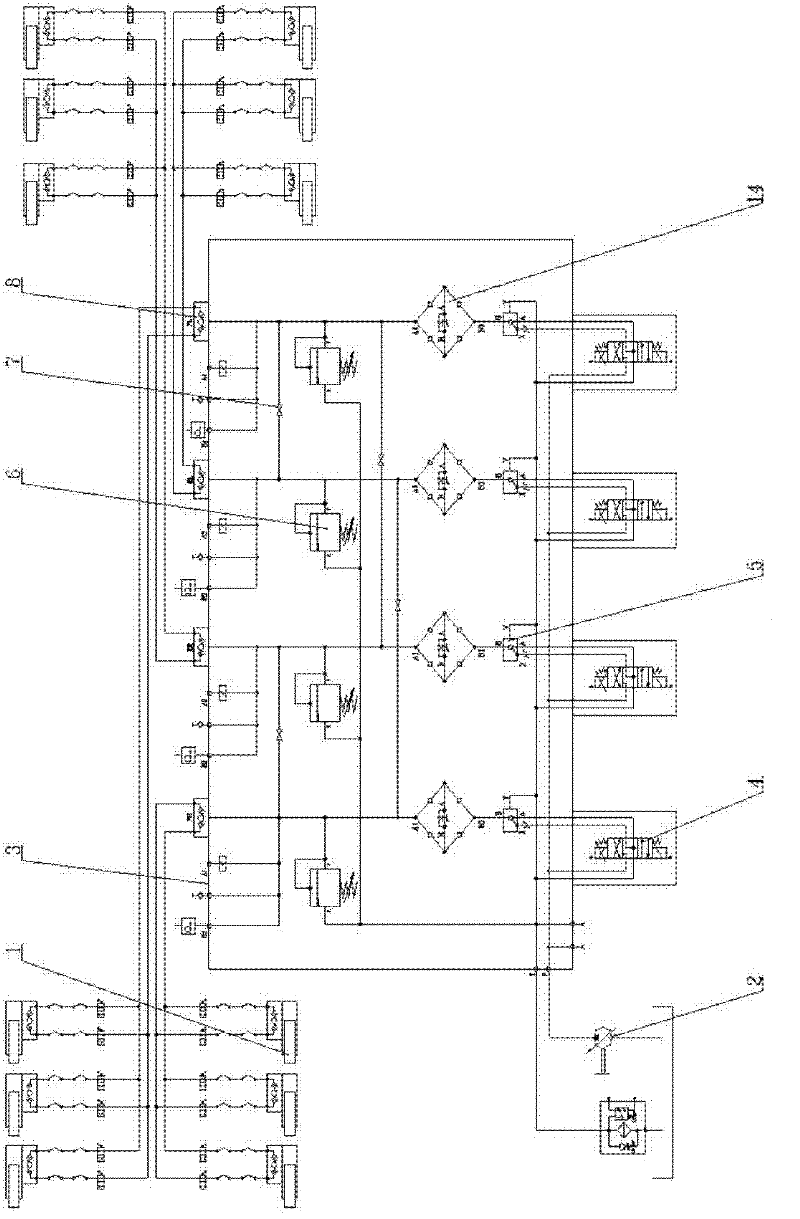

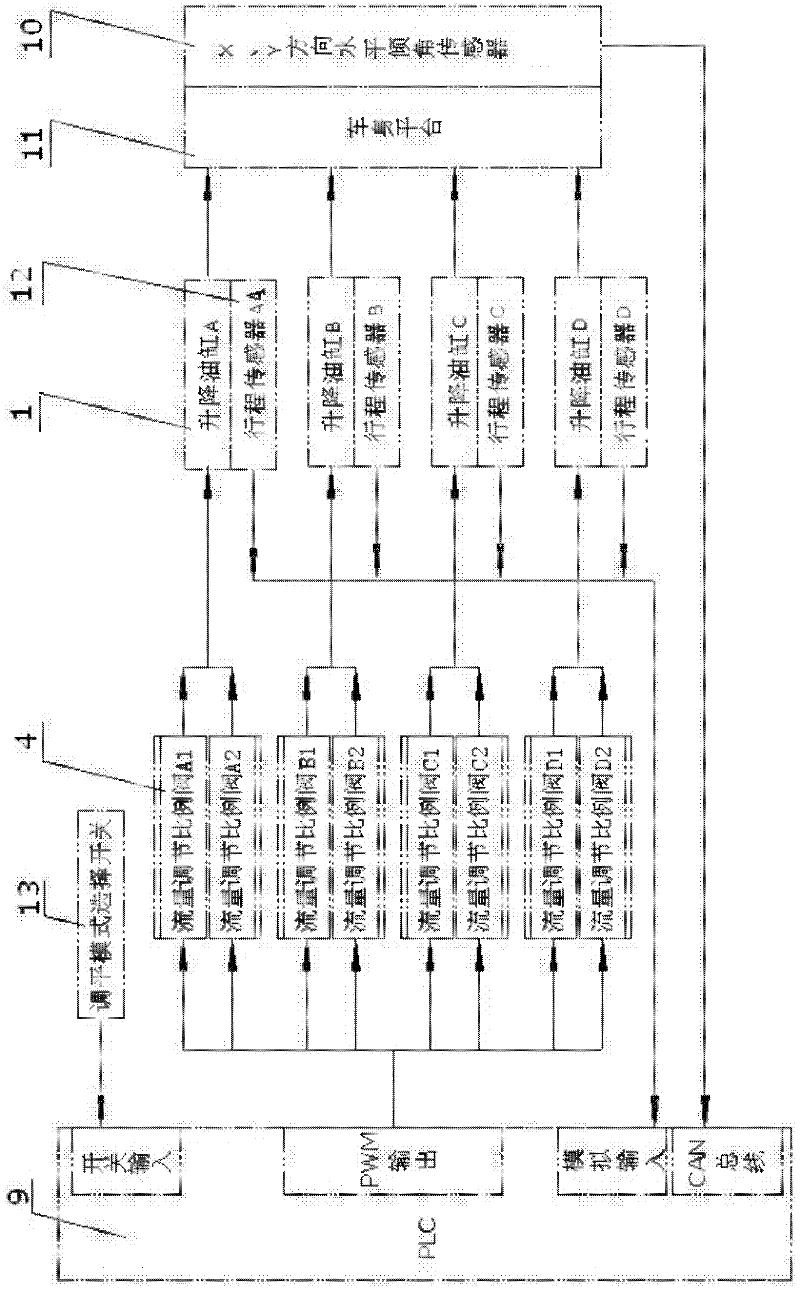

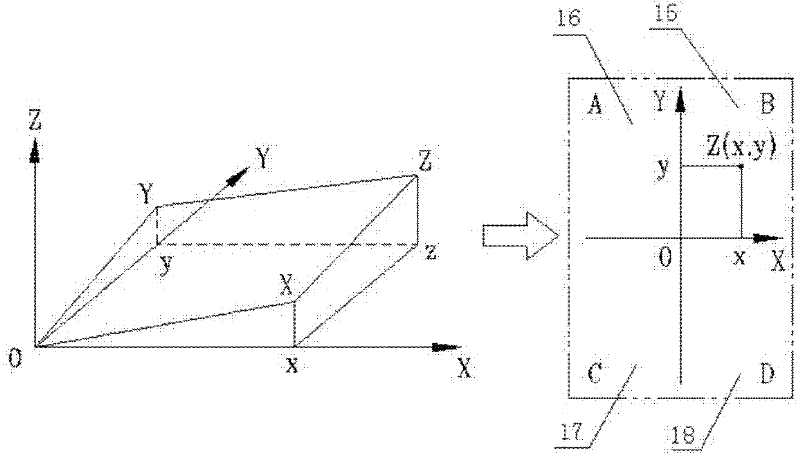

[0040] The automatic leveling system of the vehicle body platform provided by the present invention includes: a levelness detection element, a stroke sensor and a programmable controller 9 . Wherein, the level detection element is arranged on the vehicle body platform, preferably at the center of the vehicle body platform, and more preferably, the dual-axis inclination sensor 10 is used as the level detection element in the system. Divide the lifting cylinders of the body platform hydraulic lifting system into four groups according to the four corners of the body platform, that is, four supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com