Hydraulic lifter

A lift and lift mechanism technology, applied in the field of hydraulic lifts, can solve the problems of difficulty in ensuring the level, damage to multi-stage telescopic oil cylinders, and unfavorable climbing and operation of operators, and achieve the effect of ensuring levelness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

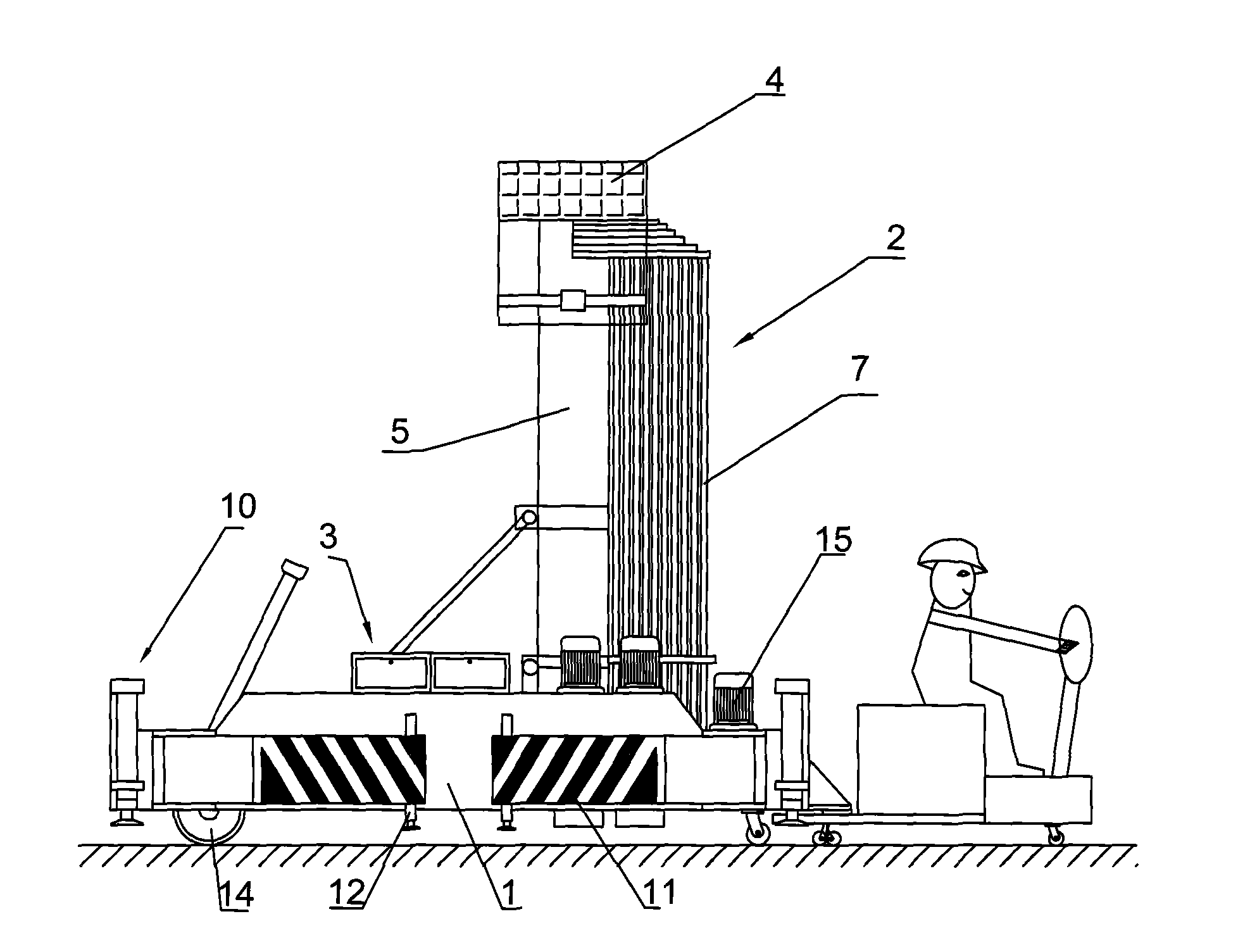

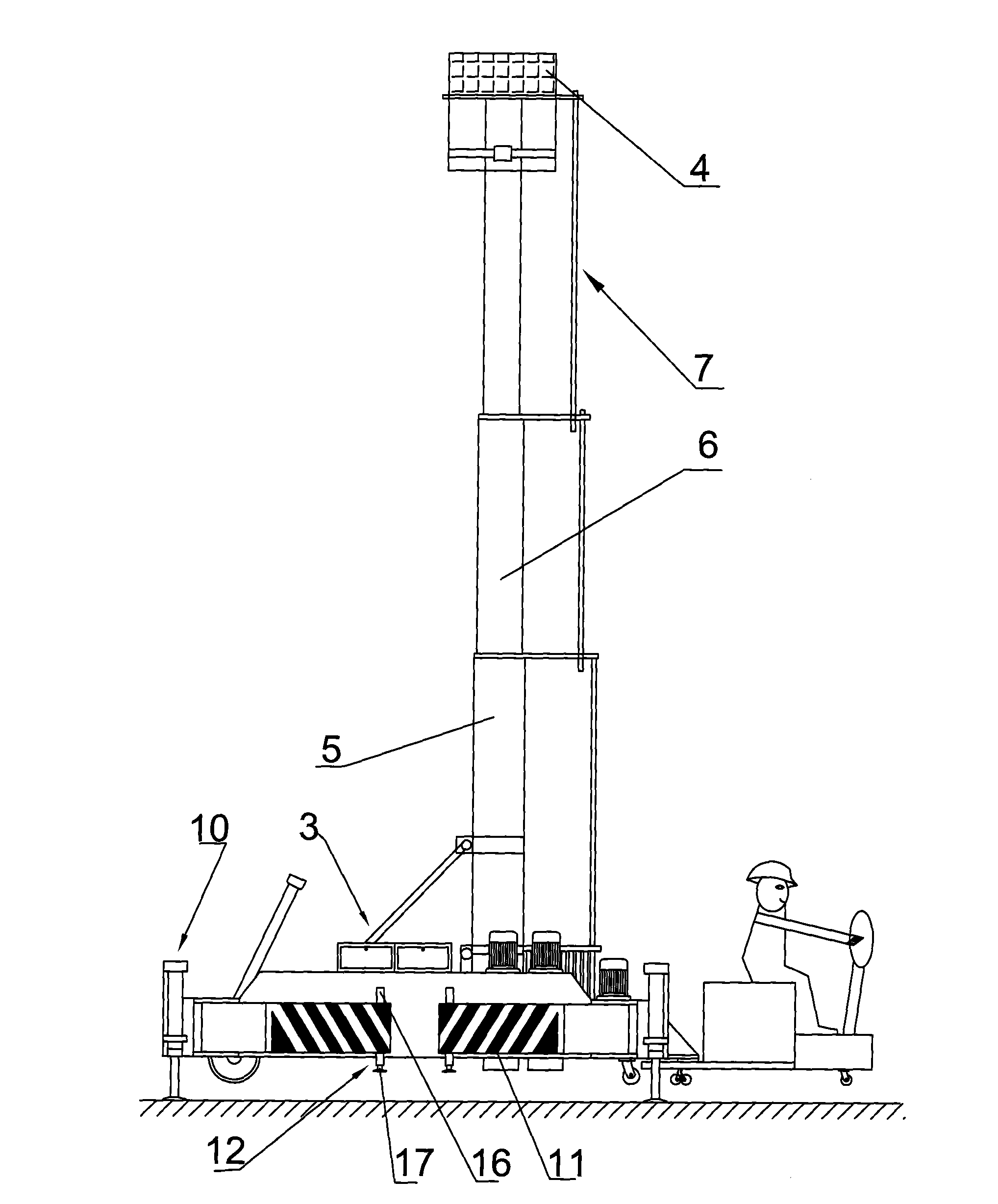

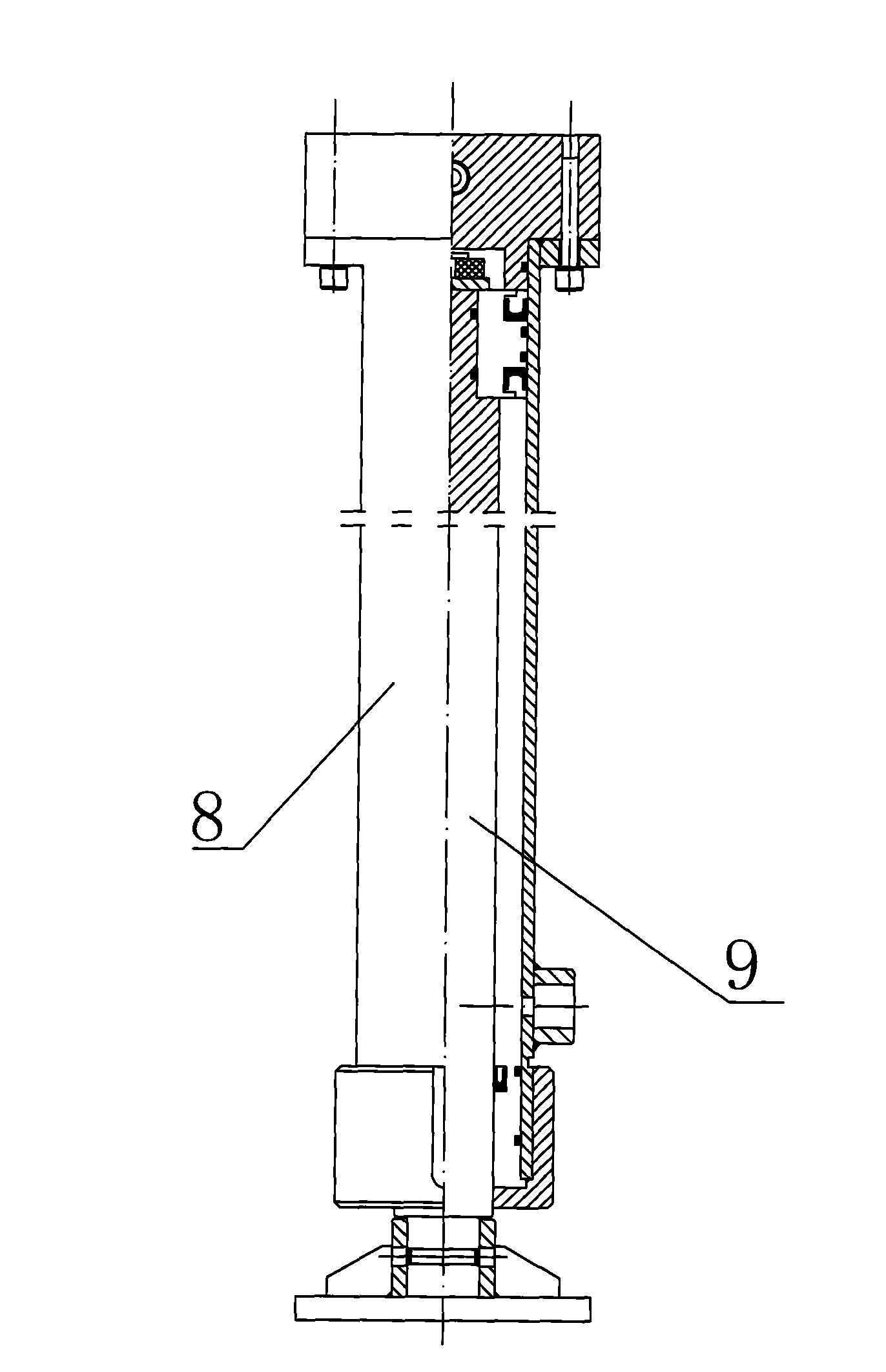

[0019] A hydraulic lift, comprising: a base 1, a lifting mechanism 2 with multi-stage telescopic oil cylinders, a work platform 4 arranged on the top of the lifting mechanism, an electro-hydraulic control mechanism 3 for driving the lifting mechanism. The lifting mechanism 2 includes The outer casing cylinder 5 fixedly arranged on the base 1, the multi-stage telescopic oil cylinder is slidably arranged in the outer casing cylinder 5, the multi-stage telescopic oil cylinder includes a plurality of cylinder sleeves 6 which are socketed step by step, and the inner cavities of the plurality of cylinder sleeves 6 are connected And it communicates with the outer casing oil cylinder 5, and with the radius reduction of each cylinder liner 6, its cross-sectional area also gradually reduces. The working platform 4 is lifted.

[0020] The bottom of the base 1 has wheels 14, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com