Leveling device and leveling robot with leveling device

A leveling device and driving device technology, applied in the field of leveling robots, can solve the problems of low efficiency and poor leveling effect, and achieve the effects of high leveling efficiency, fast speed and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

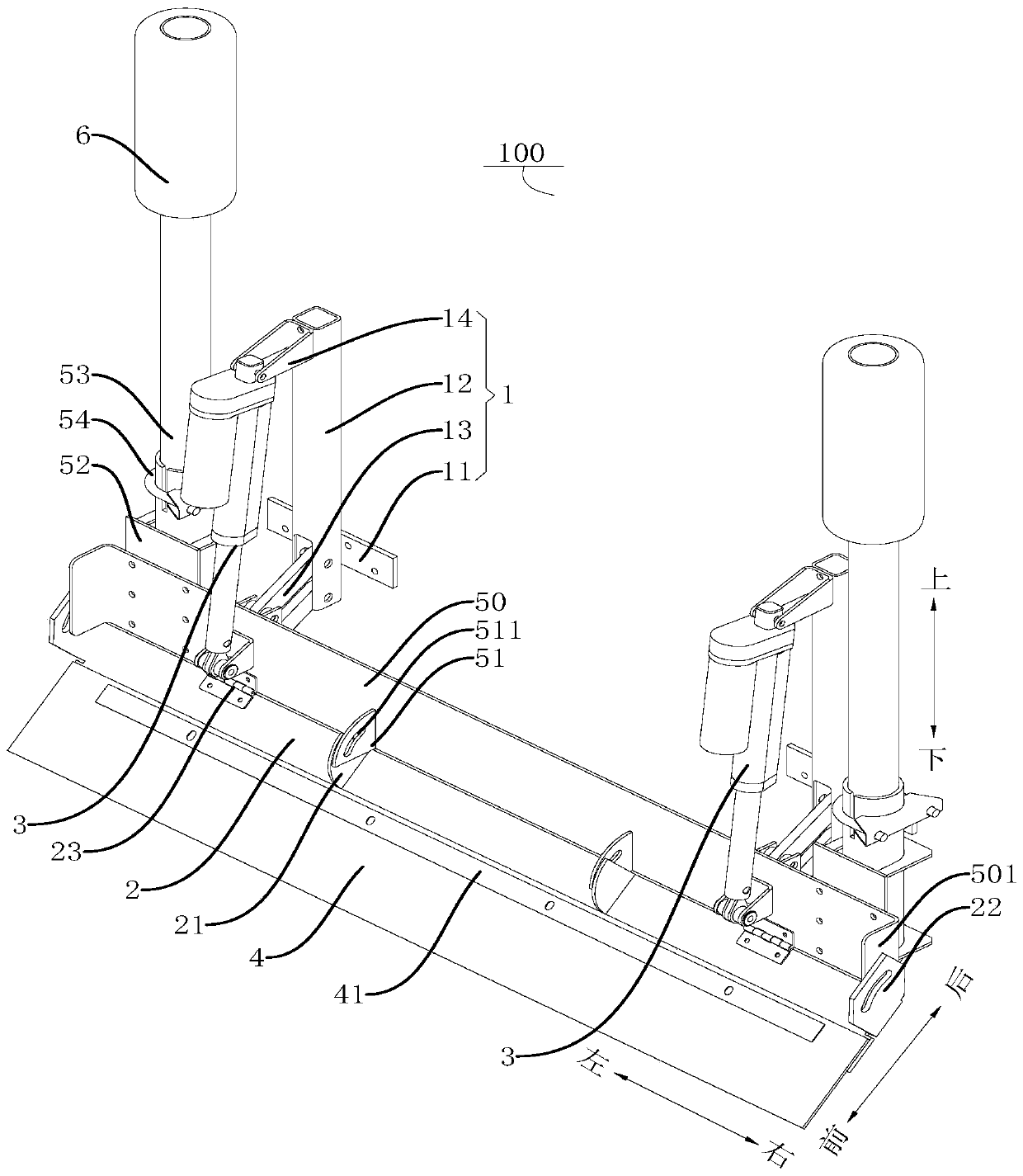

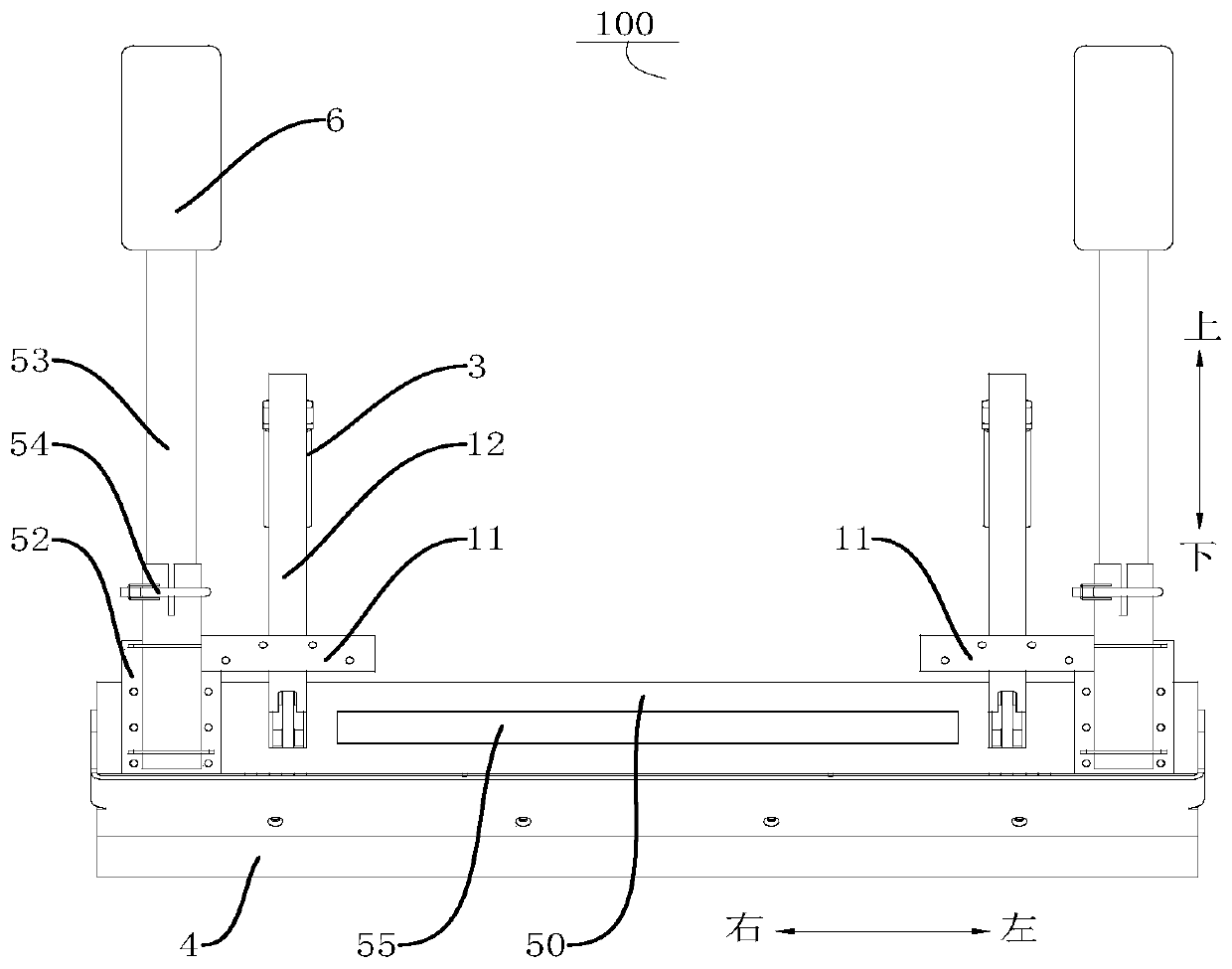

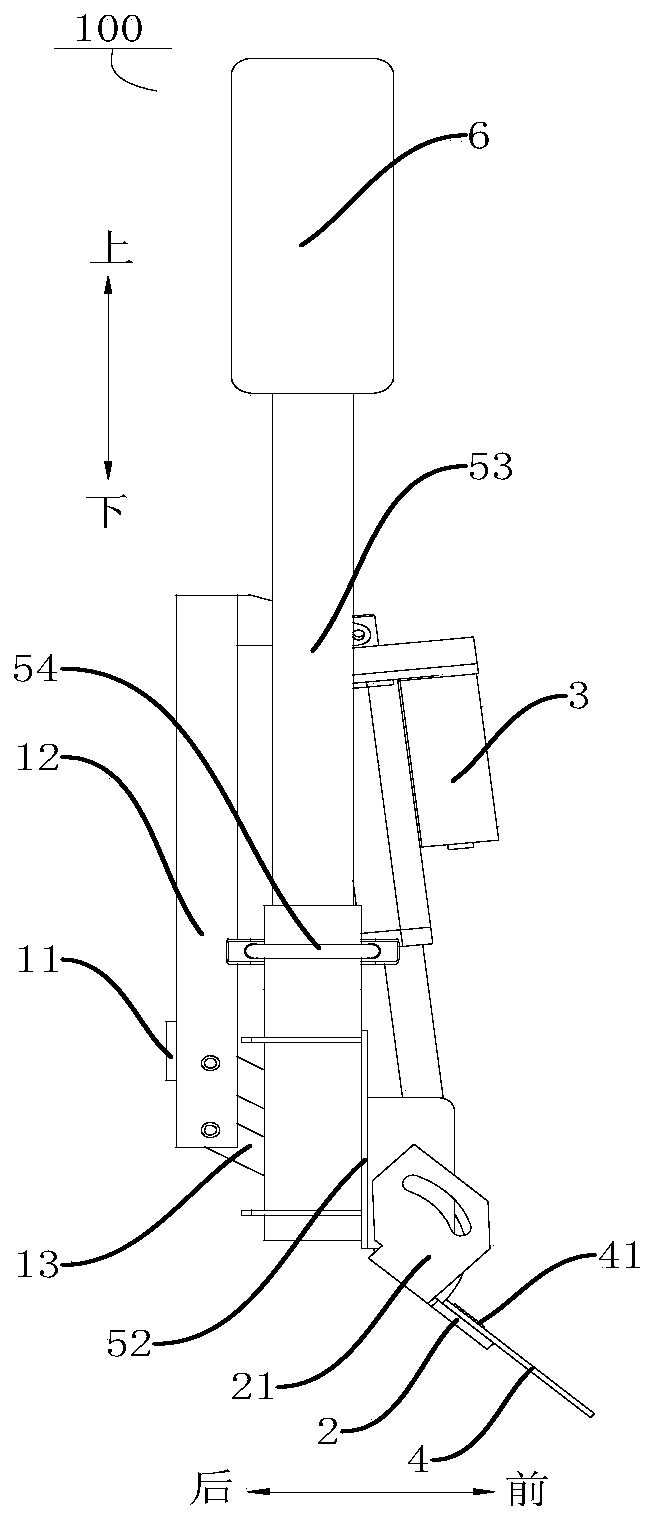

[0073] A leveling device 100, such as figure 1 As shown, it includes: a mounting frame 1 , a scraper 2 , a driving device 3 , a smoothing sheet 4 , a scraper connecting plate 50 and a laser receiver 6 .

[0074] Among them, such as figure 1 As shown, the mounting bracket 1 is used for connection and fixing. The installation frame 1 comprises two groups of fixed frames 11, the front end of the fixed frame 11 is horizontally hinged with a first hinge plate 13, the front end of the fixed frame 11 is vertically connected with a support frame 12, and the top of the support frame 12 is horizontally connected with a second hinge The connecting plate 14, the second hinged plate 14 is hinged with the driving device 3, and one end of the first hinged plate 14 is hinged with the scraper connecting plate 50, the first hinged plate 13, the driving device 3, the second hinged plate 14, The fixing frame 11 forms a quadrilateral. The driving device 3 adopts an electric push rod, the drivin...

Embodiment 2

[0079] A leveling robot 1000 includes a car body 200 and a leveling device 100. The car body 200 includes a vehicle frame 210 and a running mechanism 220. The bottom of the vehicle frame 210 is provided with a running mechanism 220 for walking during the scraping operation. The vehicle frame 210 The front part of is connected with mounting frame 1. The leveling device 100 is the leveling device 100 in the aforementioned first embodiment.

[0080] During the leveling process, the leveling robot 1000 of the present invention drives the leveling device 100 to drive through the driving of the car body 200, and the laser receiver 6 receives the laser signal fed back from the surface of the structure at any time, and controls the drive on the same side as the laser receiver 6. The device 3 adjusts up and down, and when the two sets of laser receivers 6 adjust the scraper 2 at the same time, the scraper 2 moves up and down. When there is only one group of laser receivers 6 to adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com