Construction method of prefabricated segment type pier

A construction method and segmental technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of difficult construction, short construction period, immaturity, etc., to shorten the construction period, save project cost, and reliable force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The construction method of the prefabricated segmental pier of the present invention comprises the following steps:

[0028] The first step is to prefabricate the positioning block 1, the upper segment 2 and the lower segment 3 in batches at the prefabrication site, and then transport them to the construction site;

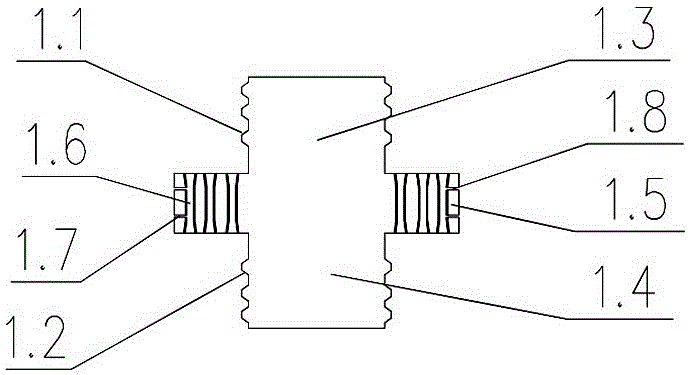

[0029] Such as figure 1 As shown, the positioning block 1 includes an upper connecting portion 1.3 and a lower connecting portion 1.4 with first shear keys 1.1, 1.2 on the surface respectively, and an annular wing 1.5 is arranged between the upper and lower connecting portions 1.3, 1.4, and the annular wing Grouting sleeves 1.6 with a length of about 40-100 cm are evenly distributed longitudinally on 1.5, and the grouting sleeves 1.6 are connected through internal grouting channels. On the outer wall of the upper and lower connecting parts 1.3, 1.4 and the annular wing 1.5 are perpendicular to each other;

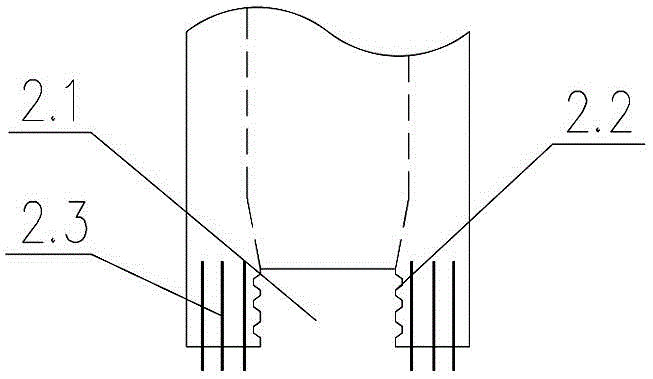

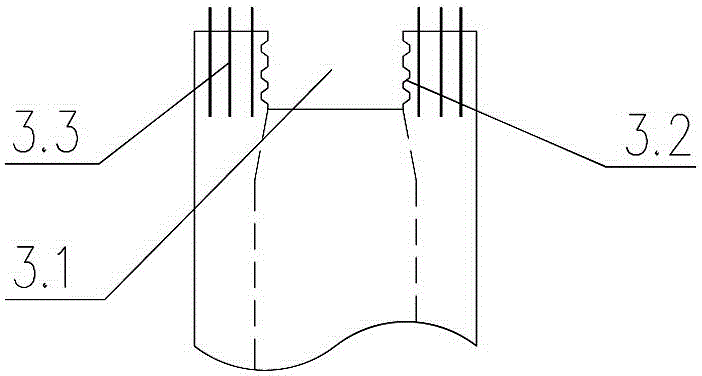

[0030] Such as figure 2 As shown, the upper se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com