Automatic rheological direct-shear apparatus and experimental operation method thereof

A direct shear instrument, fully automatic technology, applied in the direction of non-electric variable control, instruments, scientific instruments, etc., can solve the problems of reducing the utilization rate of test equipment, increasing test cost, and difficulty in combining the two into one, so as to reduce test cost, Increased utilization, full-featured results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

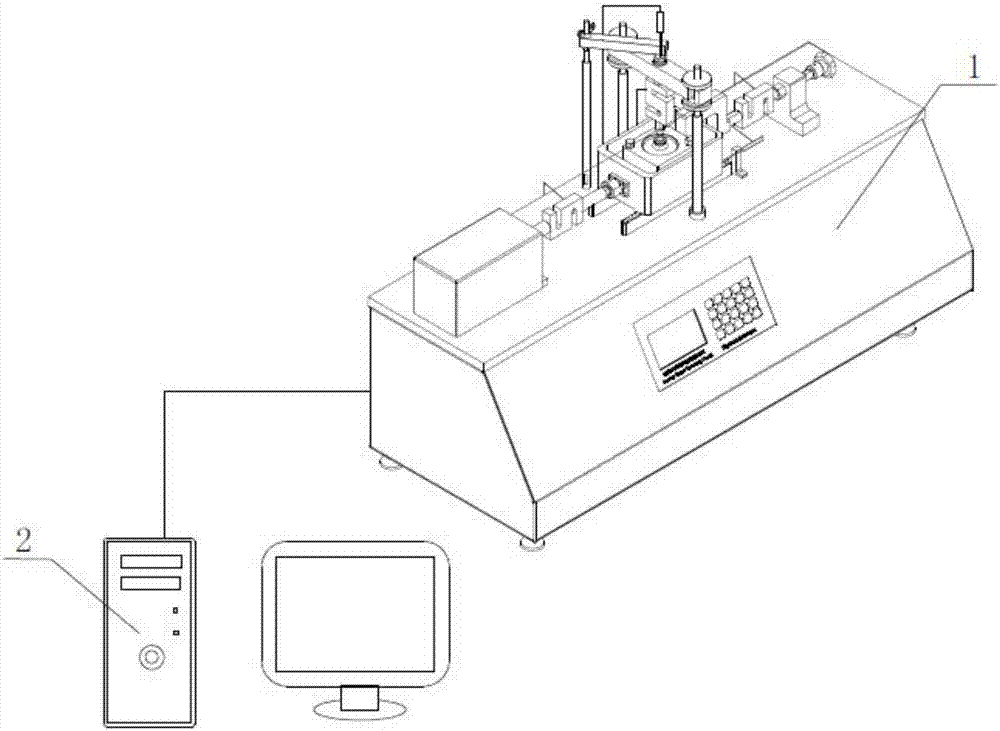

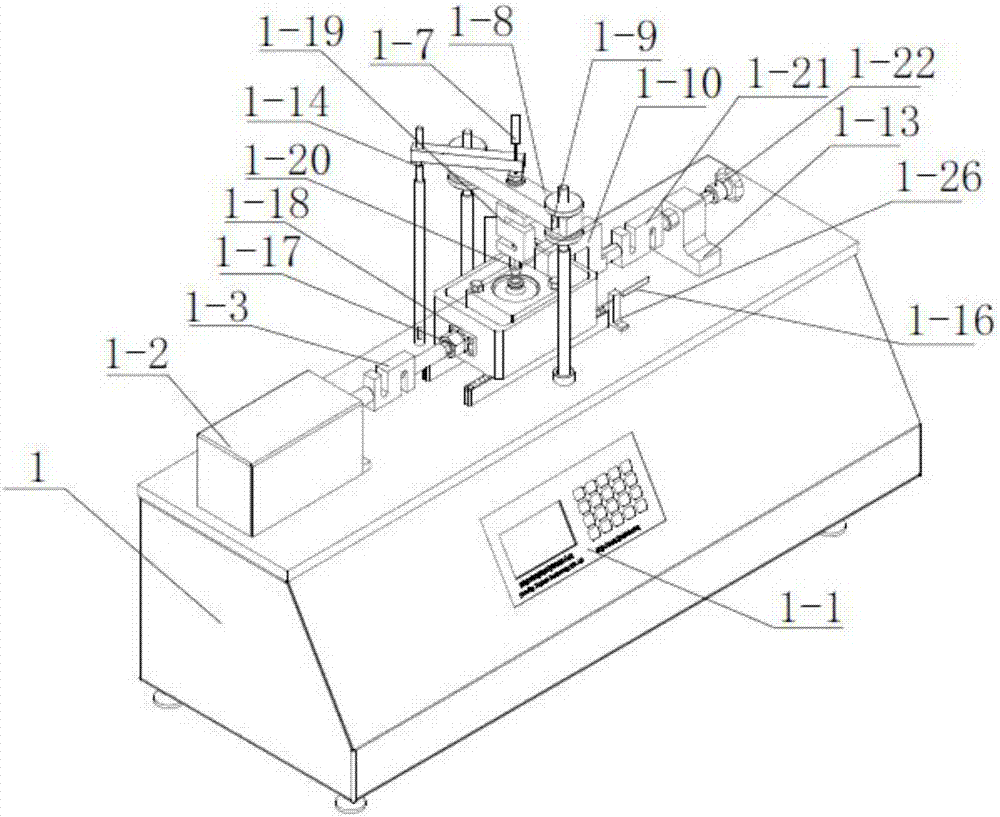

[0048] Such as Figure 1-13 Shown, a kind of automatic rheological direct shear instrument, it comprises rheological direct shear instrument 1 and computer 2, described rheological direct shear instrument 1 is connected with computer 2 through communication protocol, can pass computer 2 or rheological The control panel 1-1 on the direct shear instrument 1 realizes the control of the test process.

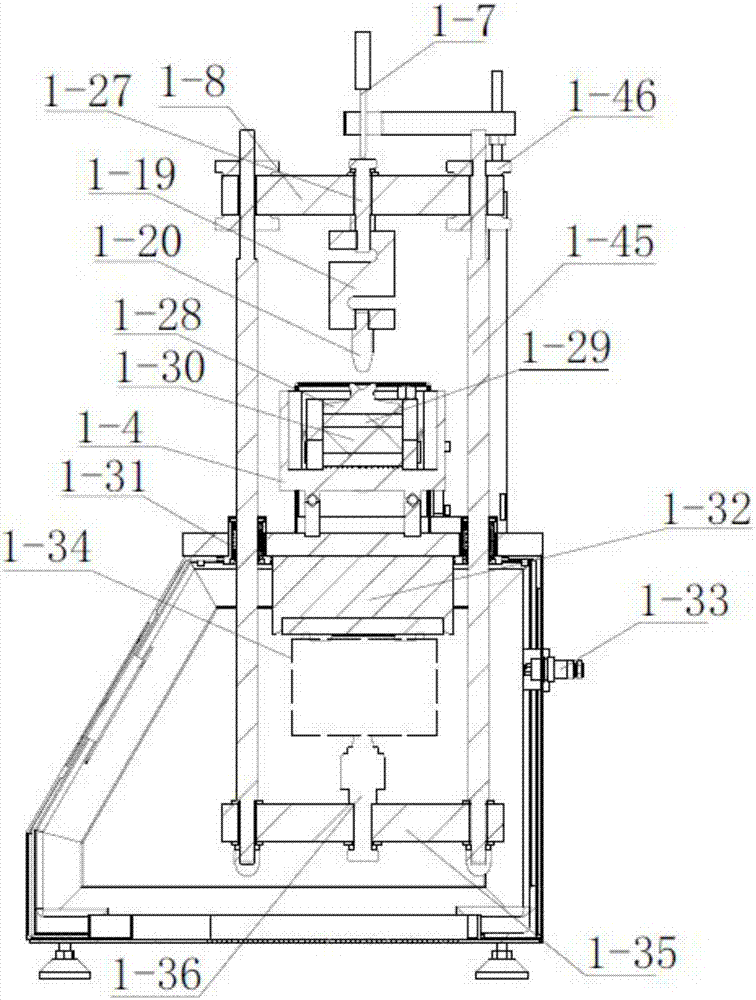

[0049] The rheological direct shear instrument 1 includes a control panel 1-1, a horizontal drive device 1-2, a first horizontal load sensor 1-3, a shear container 1-4, a track 1-5, and a vertical displacement sensor 1- 7. Upper loading beam 1-8, horizontal displacement sensor 1-16, vertical load sensor 1-19, second horizontal load sensor 1-21, lower shear box 1-23, upper shear box 1-24, bearing Gland 1-28, linear bearing 1-31, baffle plate 1-32, axial loading device 1-34, lower loading beam 1-35 and pull rod 1-45;

[0050] The horizontal driving device 1-2 is fixed on the top sur...

Embodiment 2

[0068] Such as Figure 12 As shown, the fully automatic rheological direct shear instrument, the working principle of the direct shear rheological test carried out by the fully automatic rheological direct shear instrument is:

[0069] Work operation instructions (vertical loading, horizontal shear rate, shear amount, shear force, etc.) are sent to the embedded microcomputer control system (MCU system) through the computer 2 or the control panel 1-1 buttons, and the embedded microcomputer control system will The commands are assigned to the corresponding systems of the invention:

[0070] Vertical servo loading system: The embedded microcomputer control system sends the target axial stress σ to the vertical servo loading drive device t Loading command, the vertical motor / pneumatic valve driving device drives the vertical motor 1-42 / electric control valve to work, and then the vertical worm gear reducer / air cylinder works, and pushes the lower loading beam 1 through the second...

Embodiment 3

[0073] Such as Figure 13 As shown, the fully automatic rheological direct shear instrument, the working principle of the direct shear stress relaxation test carried out by the fully automatic rheological direct shear instrument is:

[0074] Work operation instructions (vertical loading, horizontal shear rate, shear amount, shear force, etc.) are sent to the embedded microcomputer control system (MCU system) through the computer 2 or the control surface 1-1 buttons, and the embedded microcomputer control system will The commands are assigned to the corresponding systems of the invention:

[0075] Vertical servo loading system: The embedded microcomputer control system sends the target axial stress σ to the vertical servo loading drive device t Loading command, the vertical motor / pneumatic valve driving device drives the vertical motor 1-42 / electric control valve to work, and then the vertical worm gear reducer / air cylinder works, and pushes the lower loading beam 1 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com