Method for monitoring friction drag and torque of large-displacement well

A technology for extended-reach wells and torque resistance, which is used in surveying, earthmoving, wellbore/well components, etc. It can solve the problems of immature real-time monitoring of friction torque and torque, and achieve the effect of broadening the application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

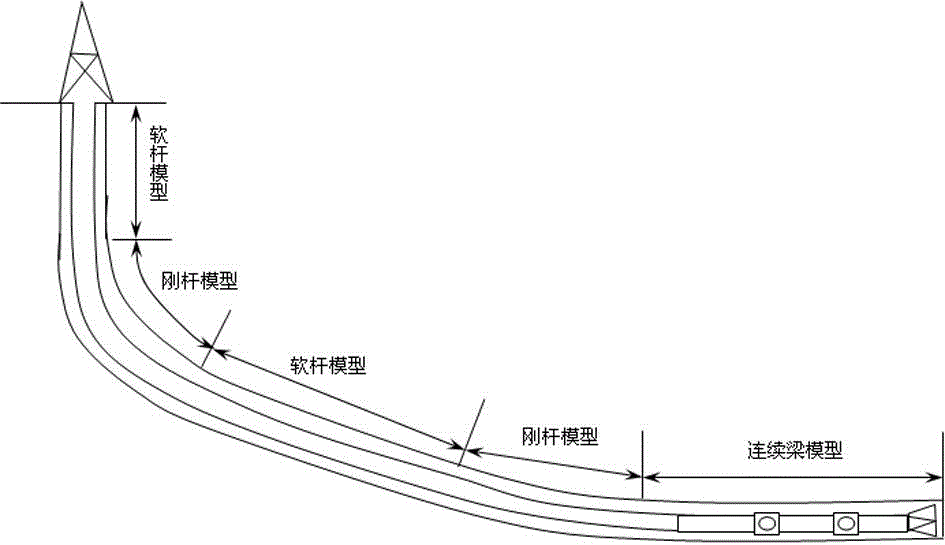

[0048] Attached below Figure 1-5 This design method is further explained.

[0049] (1) According to the characteristics of extended-reach wells, the calculation of friction torque of extended-reach well strings is divided into five parts, and the corresponding mechanical models are established: For the drill pipe section of the straight well section, due to the small change in borehole curvature, the soft pipe model of the extended reach well is established by ignoring the influence of the stiffness of the drill string; The curvature of the wellbore in the build-up section is large, and the drill string is prone to bending to cause large bending stress. In order to make the calculation more accurate, a rigid rod model is used; In the stabilizing section, the borehole curvature changes little, and the drill string is generally a drill pipe with low bending stiffness, so the soft rod model is adopted; Increase the weight of the drill pipe section, ignoring the influence o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com