Boiler secondary air damper characteristic test data processing method

A secondary air baffle and characteristic test technology, which is applied in special data processing applications, electrical digital data processing, instruments, etc., can solve the problems of increasing test costs, ignoring furnace pressure drop, and not being able to adjust with hot state operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

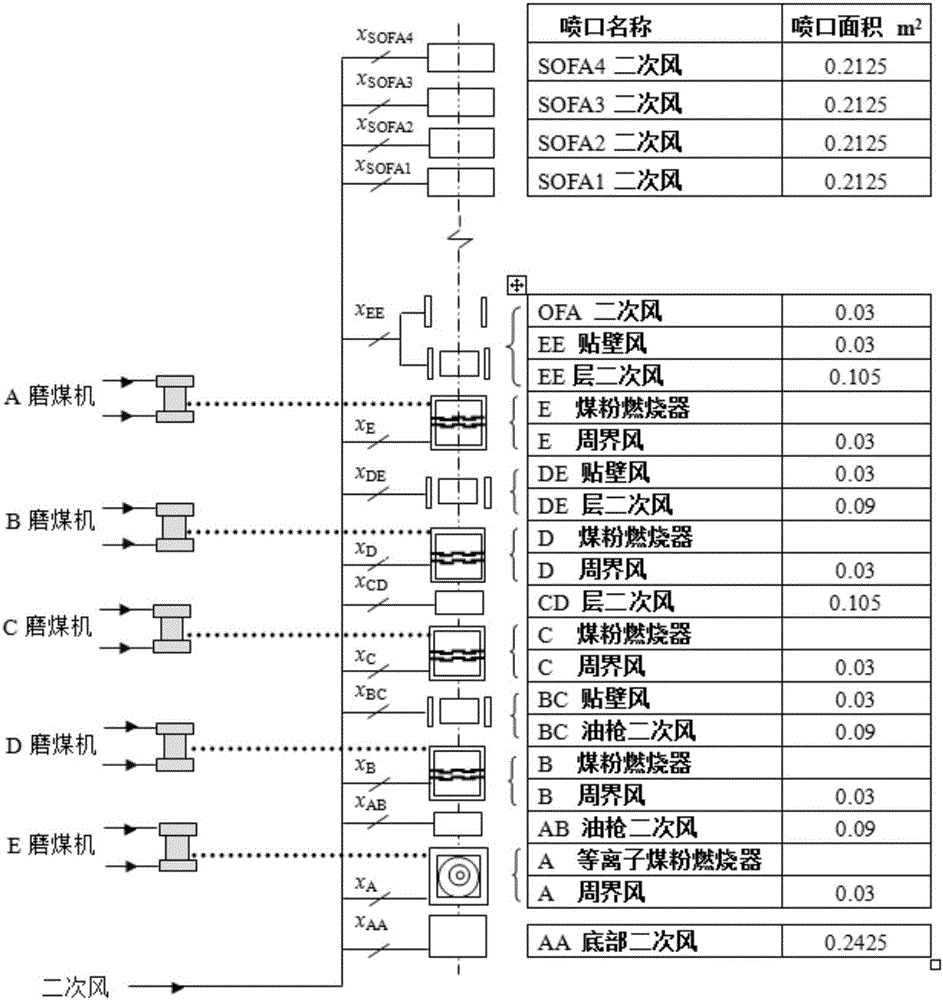

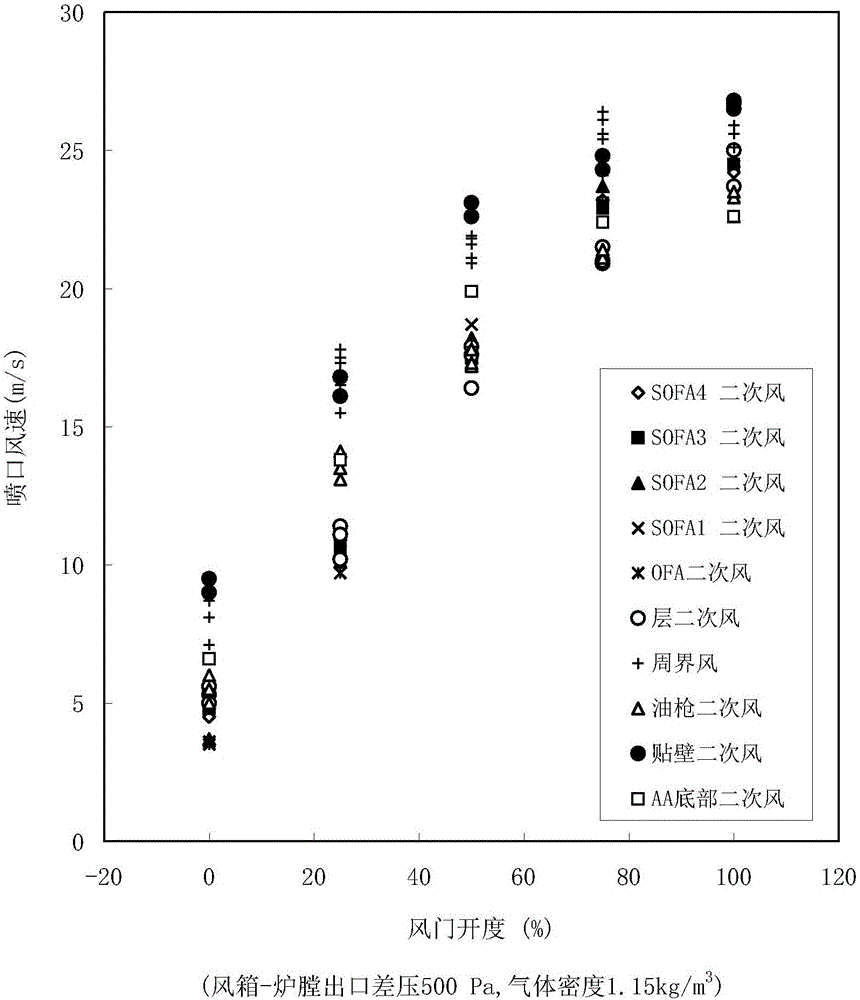

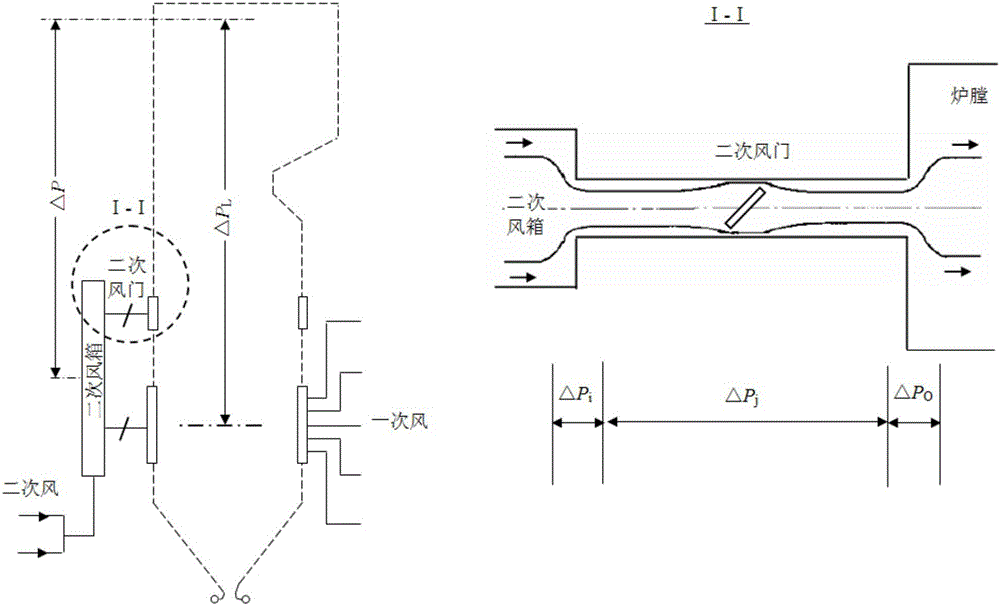

[0118] The object of implementation is a 300MW boiler, which is a subcritical, once-reheated, and controlled circulation boiler manufactured by Shanghai Boiler Factory. The boiler model is SG-1025.7 / 18.3-M840. Cut garden combustion, equipped with 5 sets of positive pressure direct blowing pulverizing system composed of RP923 coal mills, each pulverizing system supplies powder to four burners on the same floor, and the 5-layer pulverized coal burners are recorded as A, B, C, D, E, where A layer is a plasma pulverized coal burner; the layout of the secondary air nozzle is: the uppermost layer is 4 layers of separated overfire air (SeparatedOverfireAir, SOFA) nozzles, respectively SOFA1, SOFA2, SOFA3 and SOFA4; Perimeter winds are arranged around the pulverized coal burners in each layer, which are recorded as A peripheral wind, B peripheral wind, C peripheral wind, D peripheral wind, and E peripheral wind; layers AB and BC are the secondary air of the oil gun; there are 3 layers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com