Fast pugging equipment in ceramic technology and application method thereof

A kind of ceramic technology and clay refining technology, which is applied in the direction of clay processing equipment, chemical instruments and methods, and clay preparation equipment, etc. It can solve the problems of slow process, affecting artistic effect, product shrinkage, and increased deformation rate, so as to increase output, The effect of simplifying the process and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

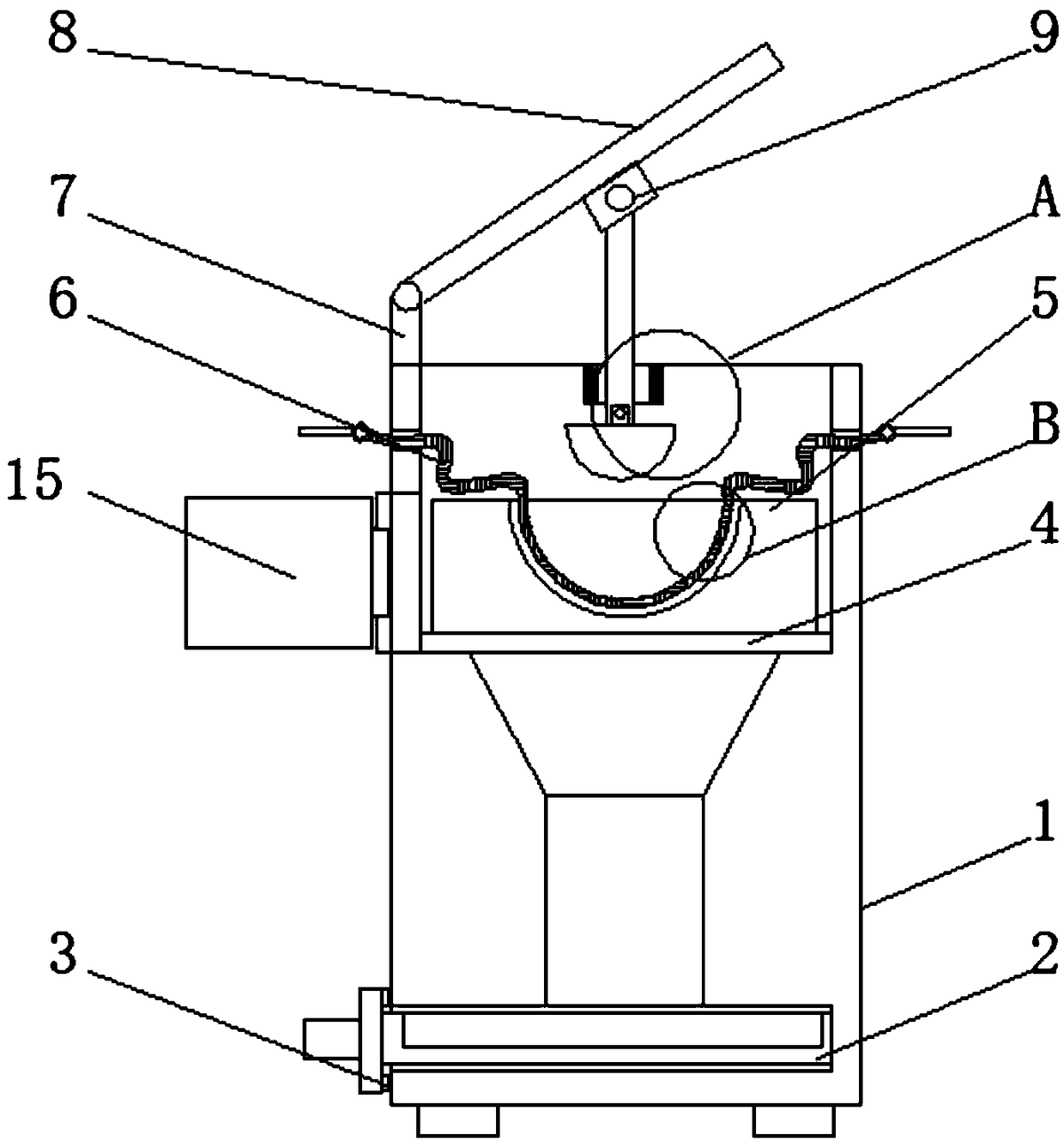

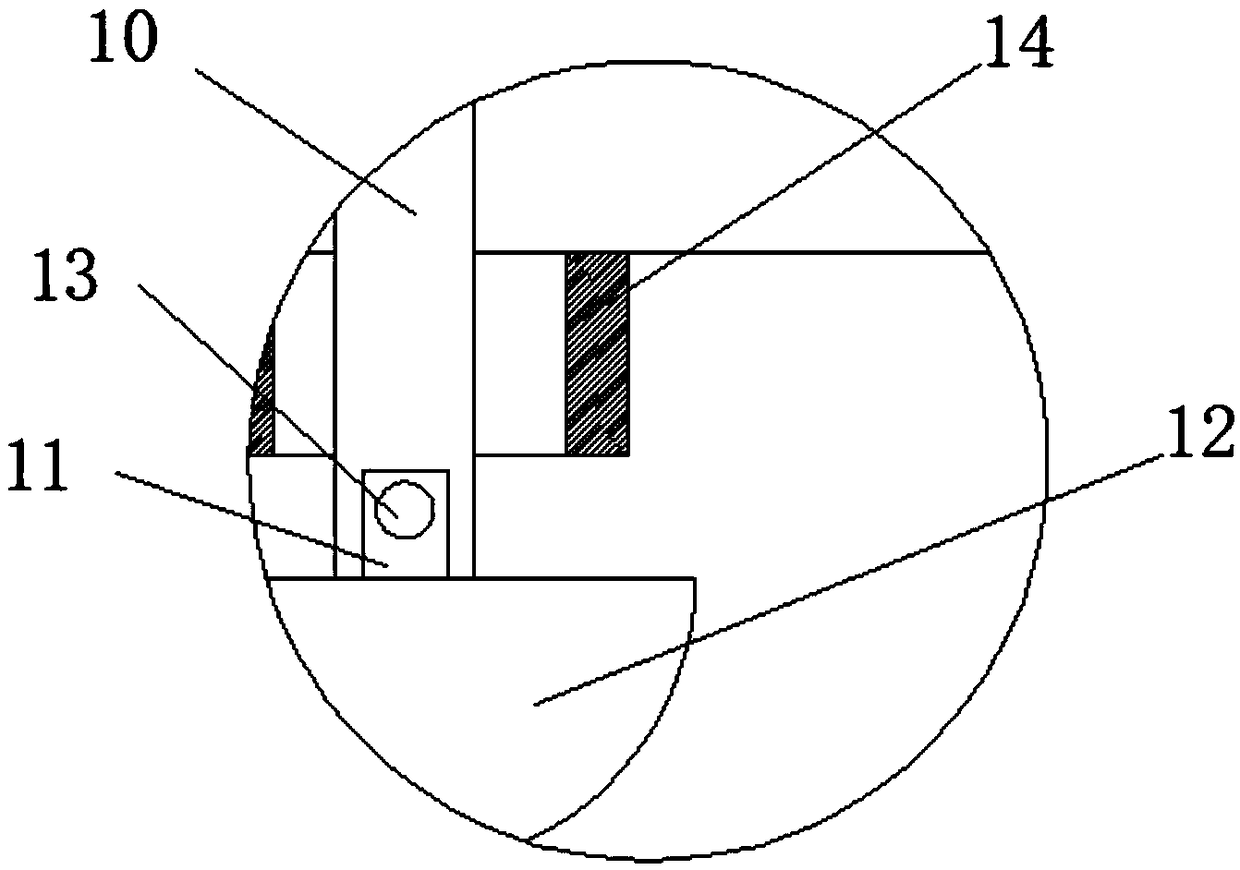

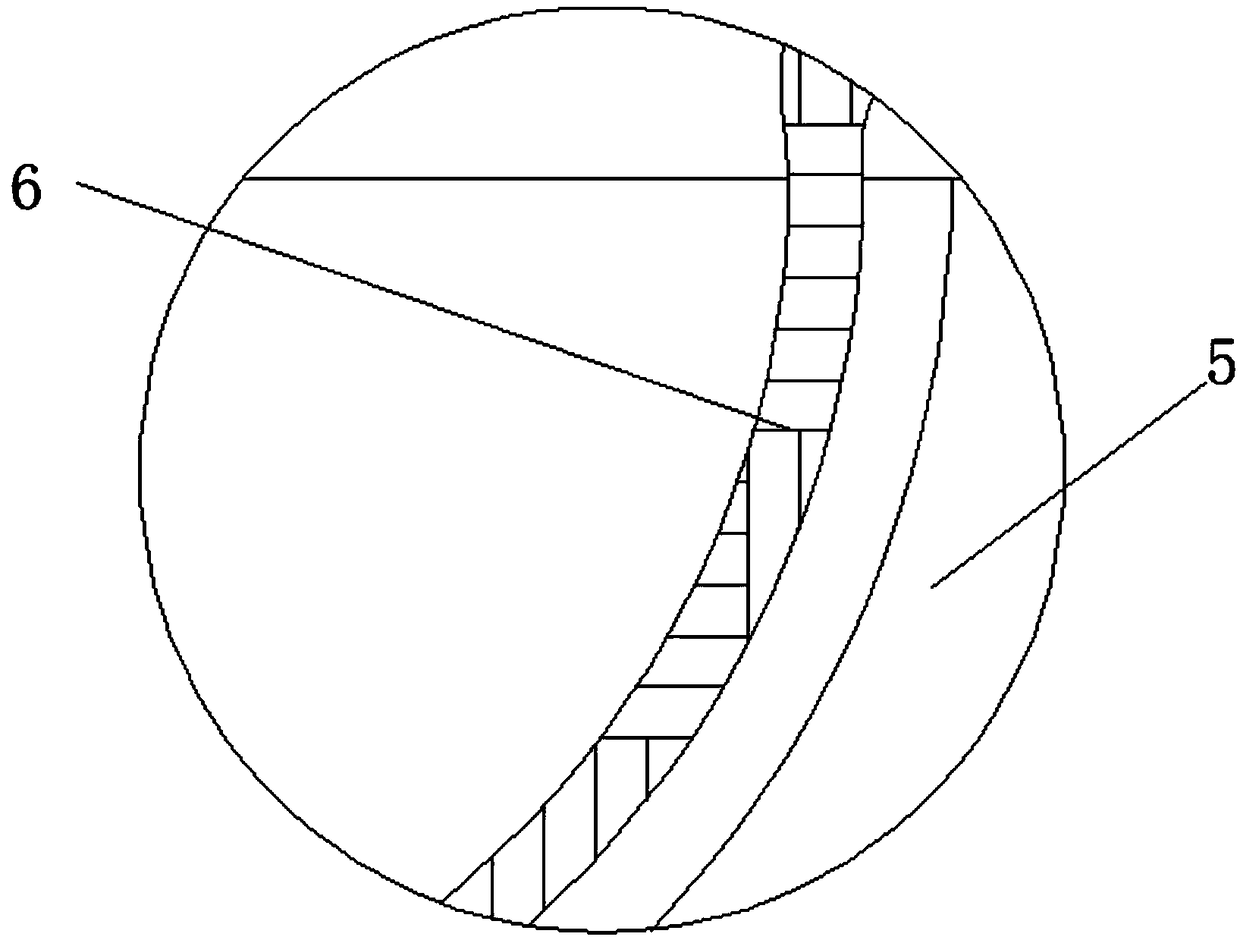

[0041] see Figure 1-7 , a kind of rapid mud refining equipment in the ceramic process, including a dual-purpose mud refining base 1, a mineral powder shifting chute is excavated at the lower end of the mud refining dual-purpose base 1, and purple sand mineral powder is slidably connected in the mineral powder shifting chute The storage box 2, the dual-purpose base for practicing mud 1 is dug with an inclined funnel in the middle, the lower end of the inclined funnel is dug with a mineral powder drop hole, the inclined funnel communicates with the mineral powder shifting chute through the mineral powder drop hole, and the upper side of the inclined funnel is provided with a rear Arriving at the shaping limiting plate 4, the inclined funnel fits with the lower end of the rear shaping limiting plate 4, and the upper side of the rear shaping limiting plate 4 is provided with a plastic anti-stick bottom pressure plate oil sludge 5, and the shaping anti-stick bottom The pressure pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com