Multifunctional photocatalytic reaction device

A photocatalytic reaction, multi-functional technology, applied in the field of chemical engineering, can solve the problems of high recovery cost, unfavorable post-processing, complex processing, etc., and achieve the effects of convenient product detection, improved light utilization rate, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

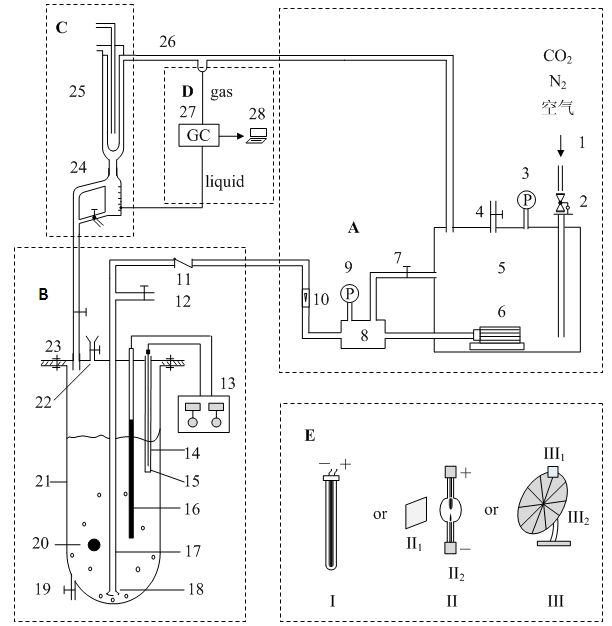

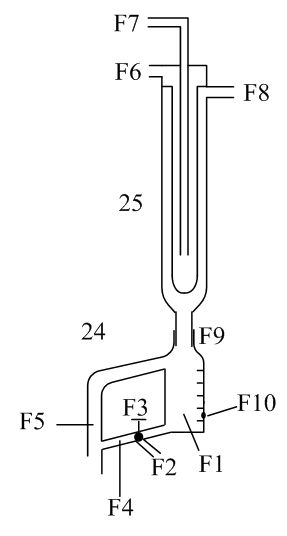

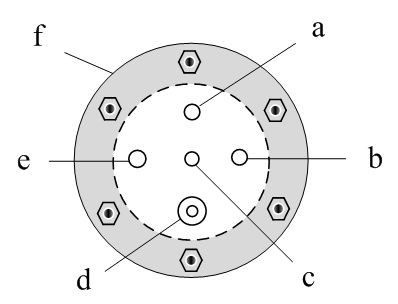

[0030] see figure 1 , The multifunctional photocatalytic reaction device of the present invention is composed of a gas circulation system, a photoreaction system, a separation system, a detection system and a light source system. The entire device is connected by pipelines, and the airtightness of the device is particularly critical. with CO 2 in H 2 Using photocatalytic reduction in O as an example, each system will be described.

[0031] 1. Gas circulation system (A)

[0032] The gas circulation system (A) includes a sealed box 5, on which a pressure reducing valve 2, a first pressure gauge 3, a vent valve 4 and a bypass regulating valve 7 are installed, and the bypass regulating valve 7 communicates with gas through a pipeline. Buffer tank 8, the second pressure gauge 9 is installed on the gas buffer tank 8, the gas buffer tank 8 is connected with the gas compressor 6, the gas buffer tank 8 is also connected to the non-return of the photoreaction system through the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com