X-ray imaging stretching fault automatic detection method for steel cable core conveying belt joint

A steel cord core and automatic detection technology, applied in image enhancement, image data processing, instruments, etc., can solve the problems of relying on manual detection, unintuitive display, low reliability, etc., achieve good use value, facilitate accurate positioning, and effectively The effect of robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

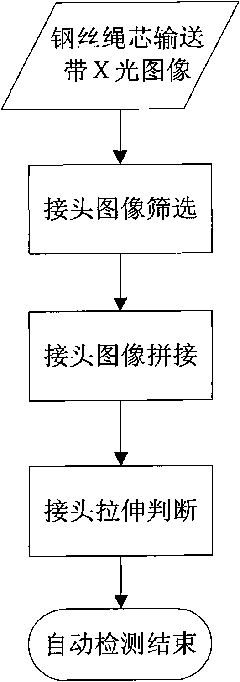

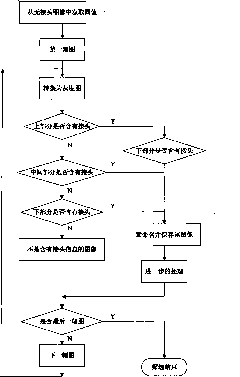

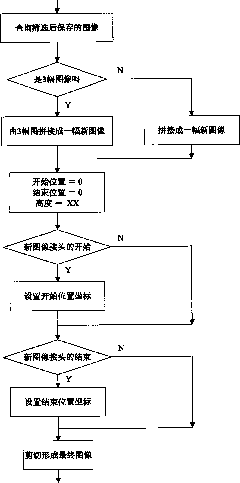

[0037] The general flowchart of the automatic detection method for the stretching failure of the steel cord conveyor belt joint proposed by the present invention is as attached figure 1As shown, for the X-ray images of a whole steel cord conveyor belt collected and saved by the X-ray imaging system, three steps are required to realize the automatic detection of joint stretching faults, namely, the screening of joint images and the splicing of joint images and joint stretch judgment. The joint image screening flow chart is attached figure 2 As shown, the joint image mosaic flow chart is attached image 3 As shown, the flow chart of judging joint stretching is as attached Figure 4 shown.

[0038] Firstly, screen the joint image, the flow chart is attached figure 2 shown. First obtain the histogram information from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com