Deep cooling and film coupled ethylene cyclic refrigeration system non-condensed effluent gas separating and recycling technology

A refrigeration system, separation and recovery technology, applied in the field of petrochemical industry, can solve the problems of ineffective recovery, unfavorable discharge of non-condensable gas, easy occurrence of total condensation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

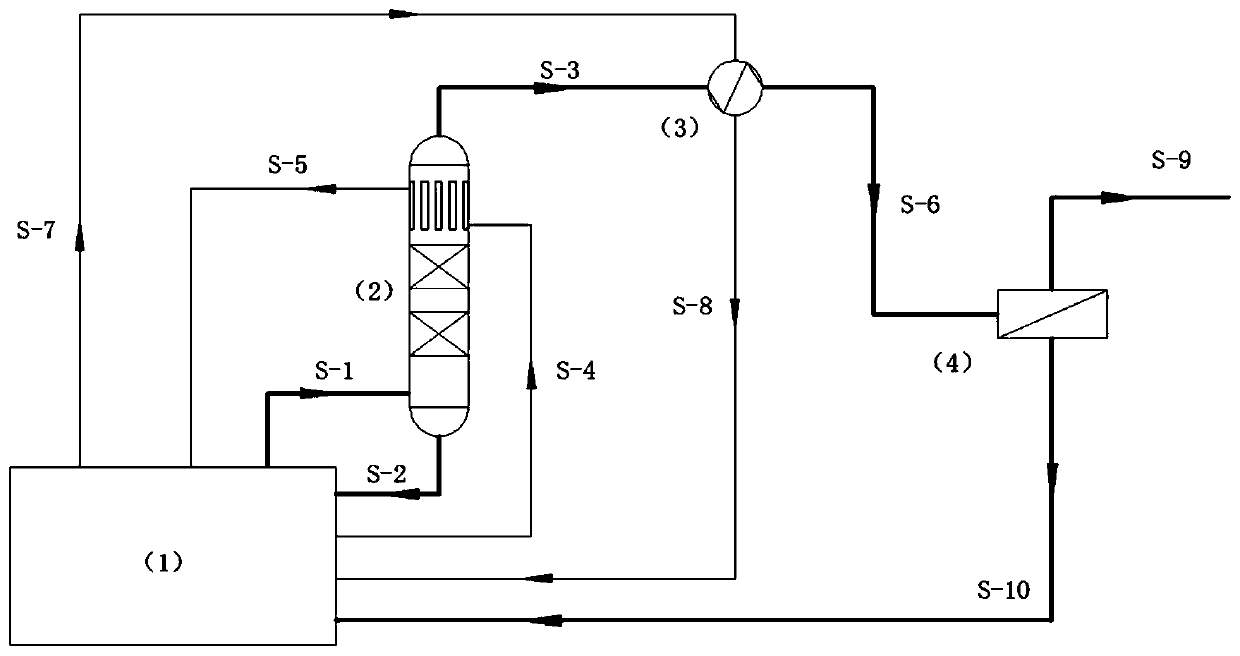

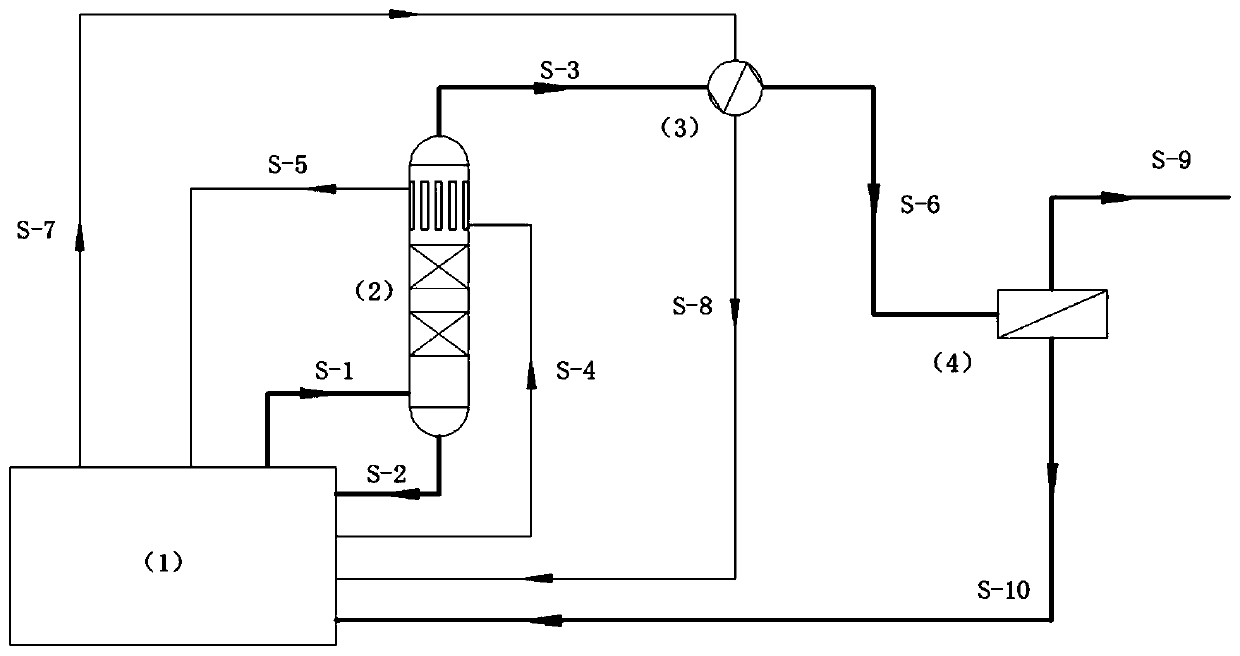

[0015] The separation and recovery process provided by the invention is used to treat the non-condensable exhaust gas produced by the ethylene circulation refrigeration system of a 60,000-ton / year butyl rubber plant. The pressure of the non-condensable exhaust gas is 1.64MPaG, the temperature is -38°C, and the ethylene content is about 97mol%, so the annual loss of ethylene is about 212 tons of ethylene.

[0016] The non-condensable exhaust gas S-1 discharged from the ethylene circulation refrigeration system 1 first enters the bottom of the rectification tower 2, and contacts with the deep condensate returning from the top of the tower in countercurrent, and the heavy component ethylene in the gas phase is cooled and liquefied, and dissolved in the deep condensate The absorbed non-condensable oxygen and nitrogen are desorbed; the liquid ethylene S-2 separated in the rectification tower 2 is returned to the ethylene circulation refrigeration system 1 from the bottom of the towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com