High proportion psendomonas syringae production strain and its fermentation method to produce psendomonas syringae

A technology of coronatin and bacterial strains, which is applied in the field of microorganisms and their fermentation production compounds, can solve the problems of high cost and unsuitability for industrial production, and achieve the effect of high coronatin production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Take the Y-2018 strain and the starting strain 011 slant strains, inoculate them on the slant medium, and culture them at 26-28°C for 2 days before use. The slant medium is: glucose 1g, beef extract 0.3g, peptone 0.5g, agar 1.5g, water 100mL, pH 7.4, sterilized at 121°C for 30 minutes.

[0046] Make 2 bottles of 100ml seed medium in 500mL Erlenmeyer flasks, one bottle is inserted into the Y-2018 strain, and the other bottle is inserted into the starting strain 011, cultivated on a shaker at 26°C for 24 hours, the speed of the rotary shaker is 160r / min, and the seeds of the shaker flask are long Ready to use later. The seed medium is: 1g of white sugar, 2g of corn steep liquor, 0.1g of ammonium sulfate, 0.1g of yeast extract, 0.15g of dipotassium hydrogen phosphate, 0.08g of magnesium sulfate, 100mL of water, pH7.4, sterilized at 121 for 30 minutes.

[0047] Make two kinds of fermentation medium, one is No. 1 medium without organic nitrogen, the formula is: white sugar ...

Embodiment 2

[0052] The formula of the culture medium used in this test is the same as that of Example 1.

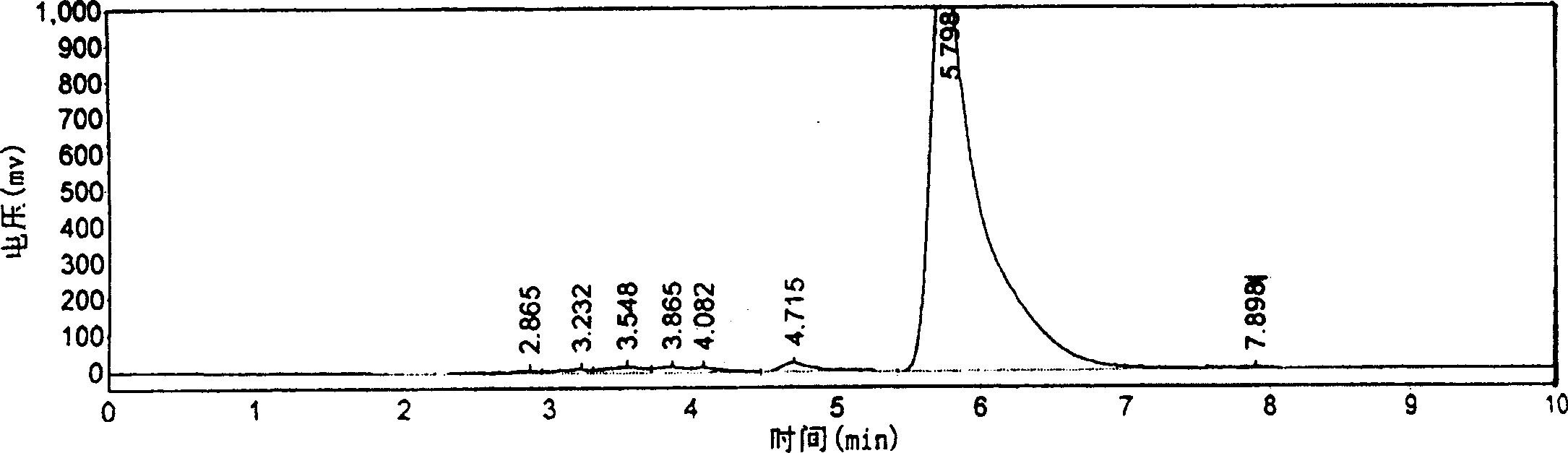

[0053] Inoculate the strains of the Y-2018 strain stored in a refrigerator at 4°C on the slant medium, and cultivate them at 28°C for 48 hours to activate them. Then connect two bacterial loops to 100mL seed medium in 500mL Erlenmeyer flasks, inoculate 3 bottles, and culture on a shaker at 26°C for 24 hours. After the seeds grow well, insert in 500mL Erlenmeyer flask 100mL fermentation medium (No. 2 medium), the inoculum size is 2%, 100 bottles in total, 28 ℃ shaker culture 4 days, merge 100 bottles to get 10L fermented liquid, use The peak area of coronatine was measured by high performance liquid chromatography. As in Example 1, the concentration of coronatin obtained from the standard sample was 36ug / mL, and the total amount of 10L coronatin was 360mg. The fermented liquid is adjusted to pH 3 and filtered, then flows through the macroporous resin (Yangzhou Pharmaceutical Factor...

Embodiment 3

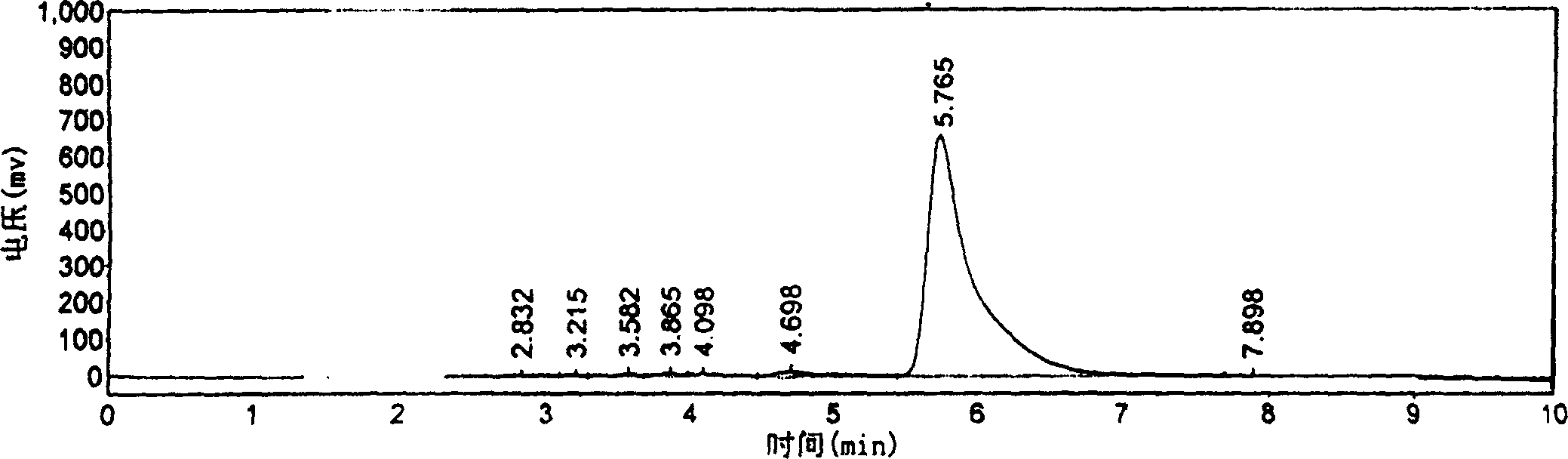

[0055] According to the seed cultivation method of Example 2, obtain 3 bottles of logarithmically grown seeds (100 mL in 500 mL Erlenmeyer flasks), then make 3 bottles of 1000 mL seed culture medium in 3000 mL Erlenmeyer flasks, and insert 100 mL of long-growing seeds respectively, at 26 ° C. Cultivate on a shaker for 18-20 hours before use. Then make the fermentation medium (i.e. No. 2 medium) of the fermenter, and add 0.03% foam enemy, prepare 150L fermentation culture liquid in the 200L fermenter, cool to 28 ℃ through sterilization, insert 3 bottles of 3000mL 1000mL long Good seeds, cultivated at 26°C for 4 days, the ventilation rate is 0.8v.v.m for 0-16 hours, 1.2v.v.m for 17-80 hours, and 0.9v.v.m for 81-96 hours. The mature fermented liquid was determined by high performance liquid chromatography, and the content of coronatin obtained by the same method as in Example 1 was 41.42ug / mL, and the total content of 150L was 6.213g. The fermented liquid is adjusted to pH 3, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com