Automatic steel ladle nitrogen adding device and automatic steel ladle nitrogen adding method

A ladle and automatic technology, applied in the field of steelmaking technology, can solve the problems that the nitrogen content is difficult to meet the requirements of nitrogen-containing steel types, the nitrogen increase amount is not accurately controlled, and human factors are greatly affected, so as to avoid manual nitrogen increase and eliminate human factors. , The effect of improving the qualified rate of steel grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

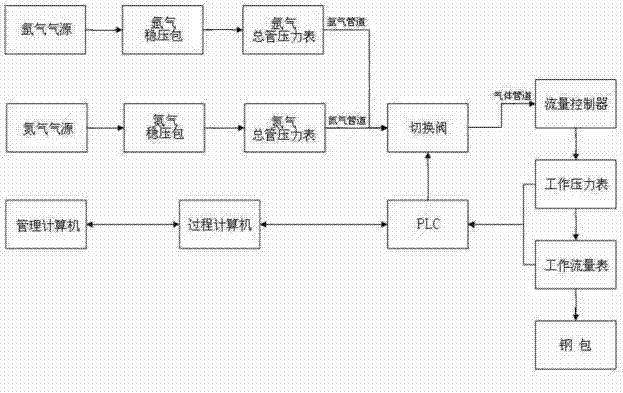

[0016] Depend on figure 1 It can be seen that the ladle automatic nitrogen increasing device of the present invention is based on the original argon gas source, argon pressure stabilizing bag, argon main pipe pressure gauge, flow controller, working pressure gauge, working flow meter, argon pipeline and gas pipeline , adding nitrogen gas source, nitrogen pressure stabilizing package, nitrogen main pipe pressure gauge, switching valve, management computer, process computer, PLC and nitrogen pipeline, and connecting the argon pipeline with the nitrogen pipeline to realize the automatic conversion between argon and nitrogen .

[0017] The specific connection method is as follows: the nitrogen gas source of the newly added nitrogen system is connected to the nitrogen pressure stabilizing package, the nitrogen main pipe pressure gauge and the switching valve in turn through the nitrogen pipeline, and the switching valve is connected to the flow controller, the working pressure gaug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com