Sugarcane juice clarifying method

A sugarcane juice and floating cleaning technology, which is applied in the fields of sucrose production, sugar juice purification, sugar production, etc., can solve the problems affecting the quality of clear juice, white sugar quality, human health, and large amount of raw materials, so as to avoid reversible reactions , Conducive to post-processing, increase the effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

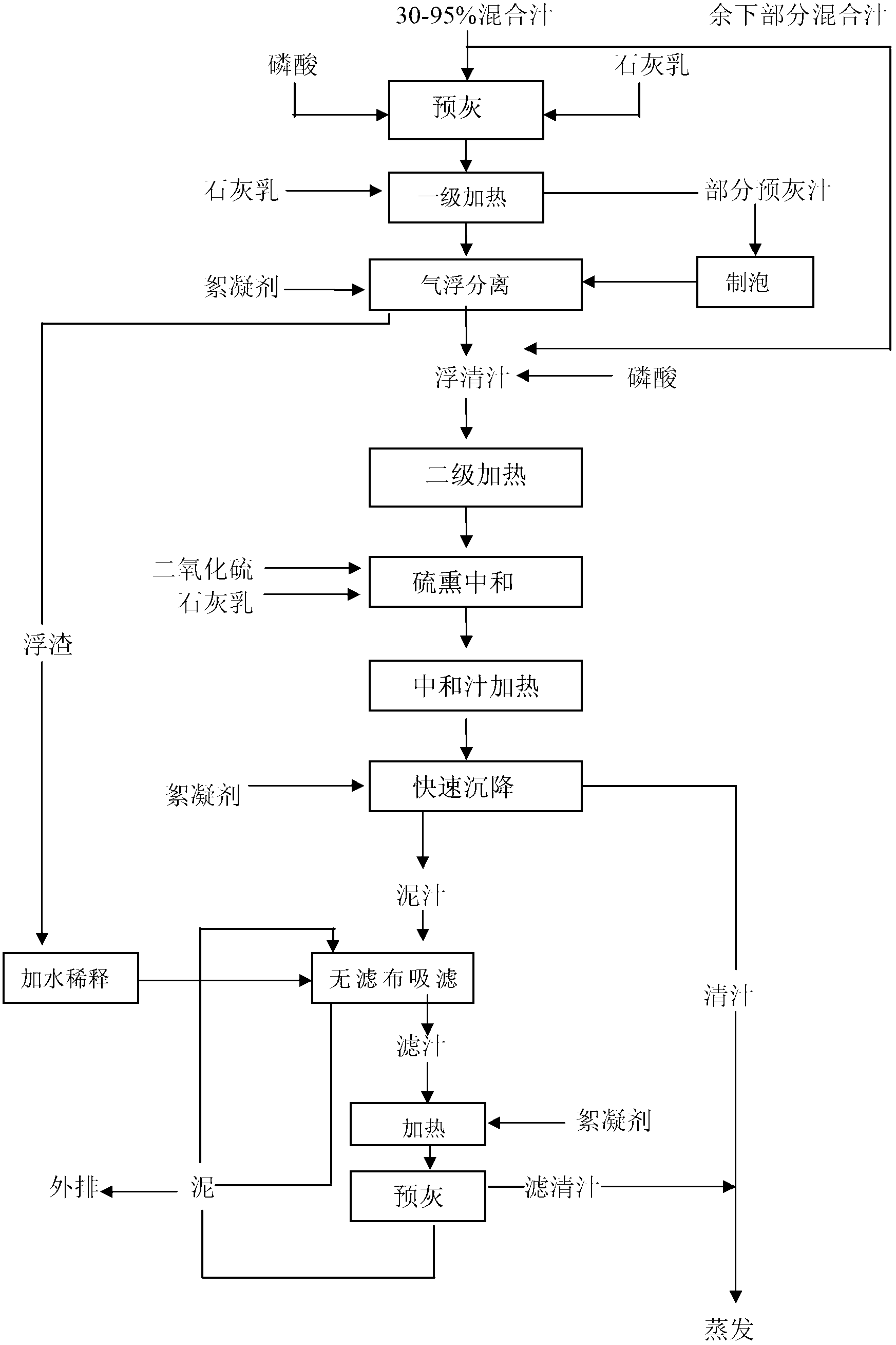

[0031] A kind of cane juice clarification method, comprises the following steps:

[0032] 1. Pre-lime: Take the mixed juice accounting for 95% of the total weight of the mixed juice, add 0.020% phosphoric acid to sugarcane ratio, and adjust the pH value of the solution to 7.2 with milk of lime to obtain pre-lime juice.

[0033] 2. Primary heating: add milk of lime to the pre-lime juice, adjust the pH value of the solution to 8.5, pump it into the primary heater for heating, and the temperature is 45°C.

[0034] 3. Bubble making: The pre-lime juice after primary heating flows into the storage tank above the floater, part of the pre-lime juice enters the bubble maker to make bubbles, and the obtained fine, uniform and active bubbles are obtained, and the remaining part of the pre-lime juice is used for future use.

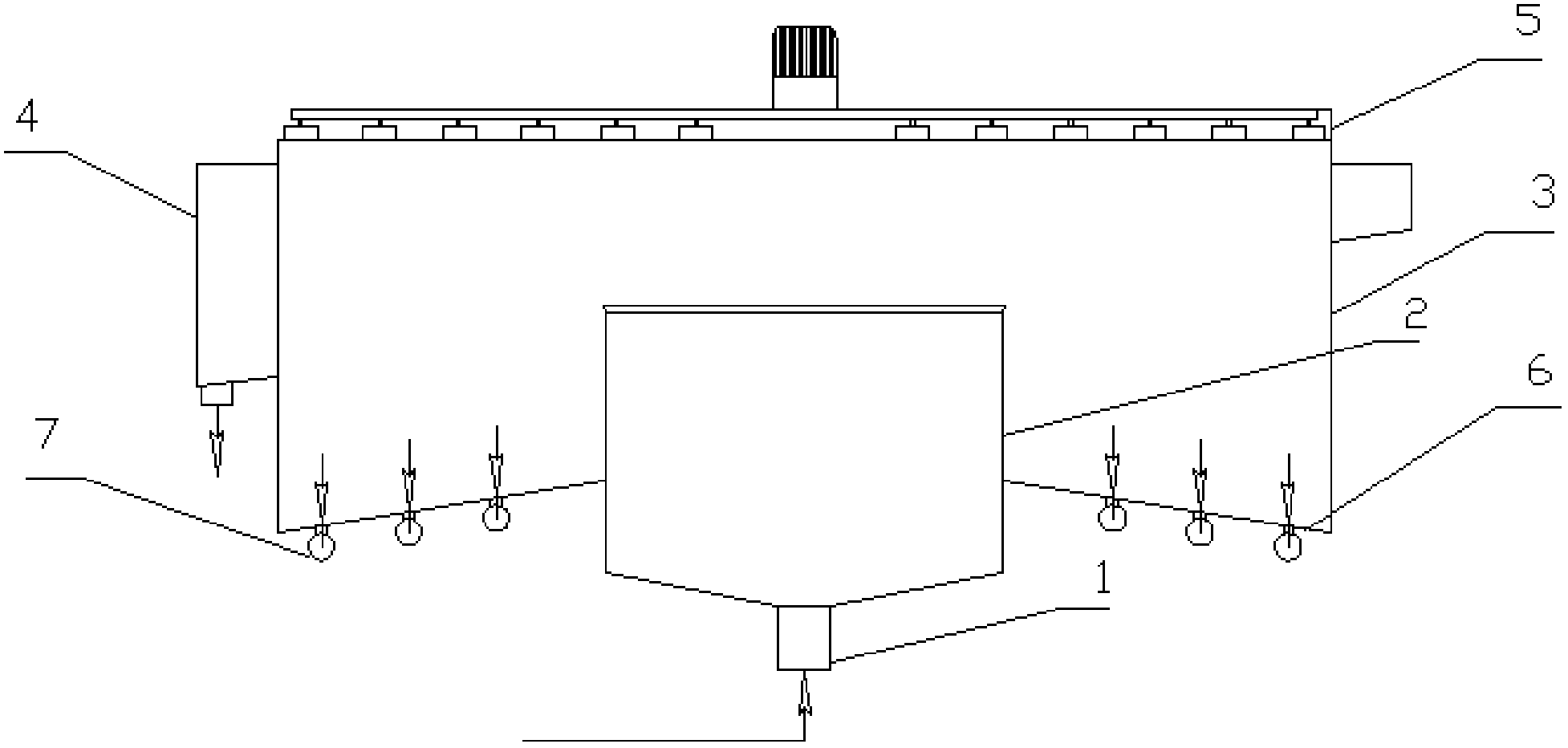

[0035] 4. Air flotation separation: Add 5PPM polyacrylamide to the remaining part of the pre-lime juice, add the prepared air bubbles, mix well, pump it into the jui...

Embodiment 2

[0042] A kind of cane juice clarification method, comprises the following steps:

[0043] 1. Pre-lime: Take the mixed juice accounting for 40% of the total weight of the mixed juice, add 0.018% phosphoric acid to sugarcane ratio, and adjust the pH value of the solution to 7.0 with milk of lime to obtain pre-lime juice.

[0044] 2. Primary heating: add milk of lime to the pre-lime juice, adjust the pH value of the solution to 8.2, pump it into the primary heater for heating, and the temperature is 48°C.

[0045] 3. Bubble making: The pre-lime juice after primary heating flows into the storage tank above the floater, part of the pre-lime juice enters the bubble maker to make bubbles, and the obtained fine, uniform and active bubbles are obtained, and the remaining part of the pre-lime juice is used for future use.

[0046] 4. Air flotation separation: Add 2PPM chitosan to the remaining part of the pre-lime juice, add the prepared air bubbles, mix well, pump into the juice inlet ...

Embodiment 3

[0053] A kind of cane juice clarification method, comprises the following steps:

[0054] 1. Pre-lime: Take the mixed juice accounting for 30% of the total weight of the mixed juice, add 0.015% phosphoric acid to sugarcane ratio, and adjust the pH value of the solution to 6.8 with milk of lime to obtain pre-lime juice.

[0055] 2. Primary heating: Add milk of lime to the pre-lime juice, adjust the pH value of the solution to 8.0, pump it into the primary heater to heat, and the temperature is 50°C.

[0056] 3. Bubble making: The pre-lime juice after primary heating flows into the storage tank above the floater, part of the pre-lime juice enters the bubble maker to make bubbles, and the obtained fine, uniform and active bubbles are obtained, and the remaining part of the pre-lime juice is used for future use.

[0057] 4. Air flotation separation: Add 1PPM polyacrylamide to the remaining part of the pre-lime juice, add the prepared air bubbles, mix well, pump it into the juice i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com