Expandable sieve pipe performance detection experiment apparatus and expandable sieve pipe performance evaluation method

An experimental device and screen tube technology, which is applied in the direction of measuring device, strength characteristics, and the use of stable tension/pressure test material strength, etc., can solve the problems of inability to evaluate the overall performance of expandable screen tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

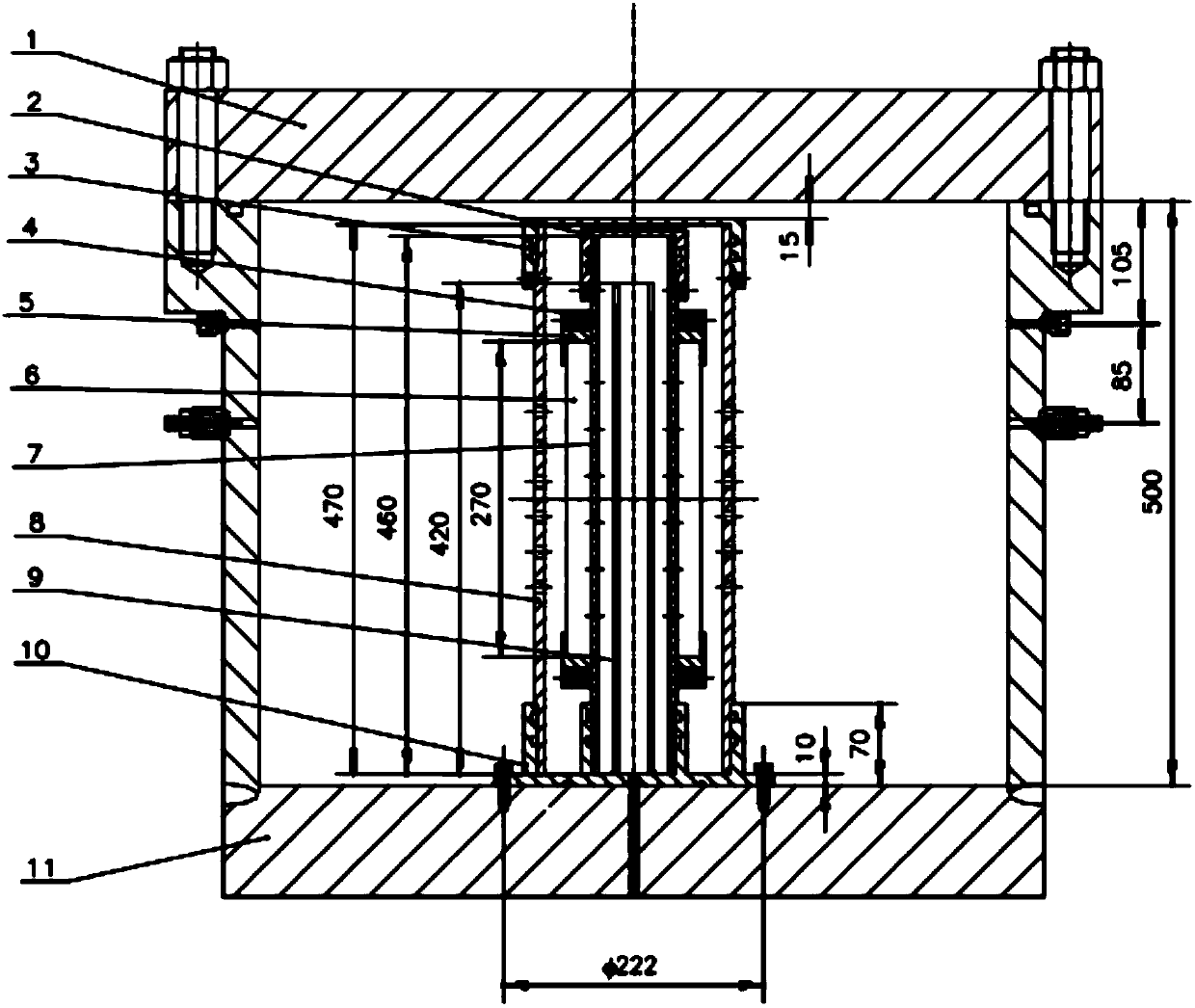

[0055] Below in conjunction with accompanying drawing, the present invention is described in further detail:

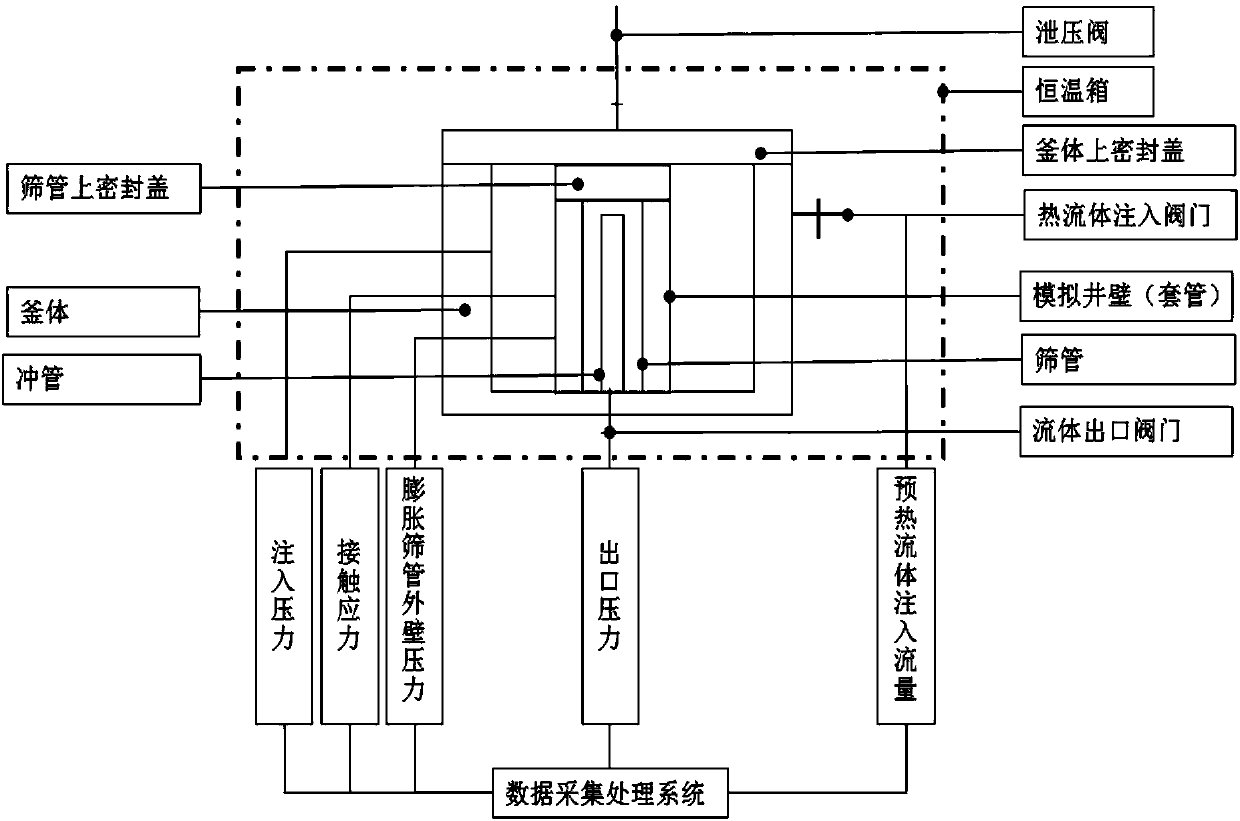

[0056] The device of the present invention accurately tracks the changes of temperature, pressure and flow by simulating the downhole temperature, sand control mode, and sand control parameter change conditions, using flowmeters, pressure sensors, sand collectors, and data acquisition and processing systems; through the evaluation method, the experimental The calculation and analysis of the data can intuitively reflect the flow capacity, anti-clogging ability, sand retaining precision and sand retaining ability of the screen, make an accurate judgment on the overall performance of the screen, and provide further support for the rational selection and application of the sand control screen. strong basis.

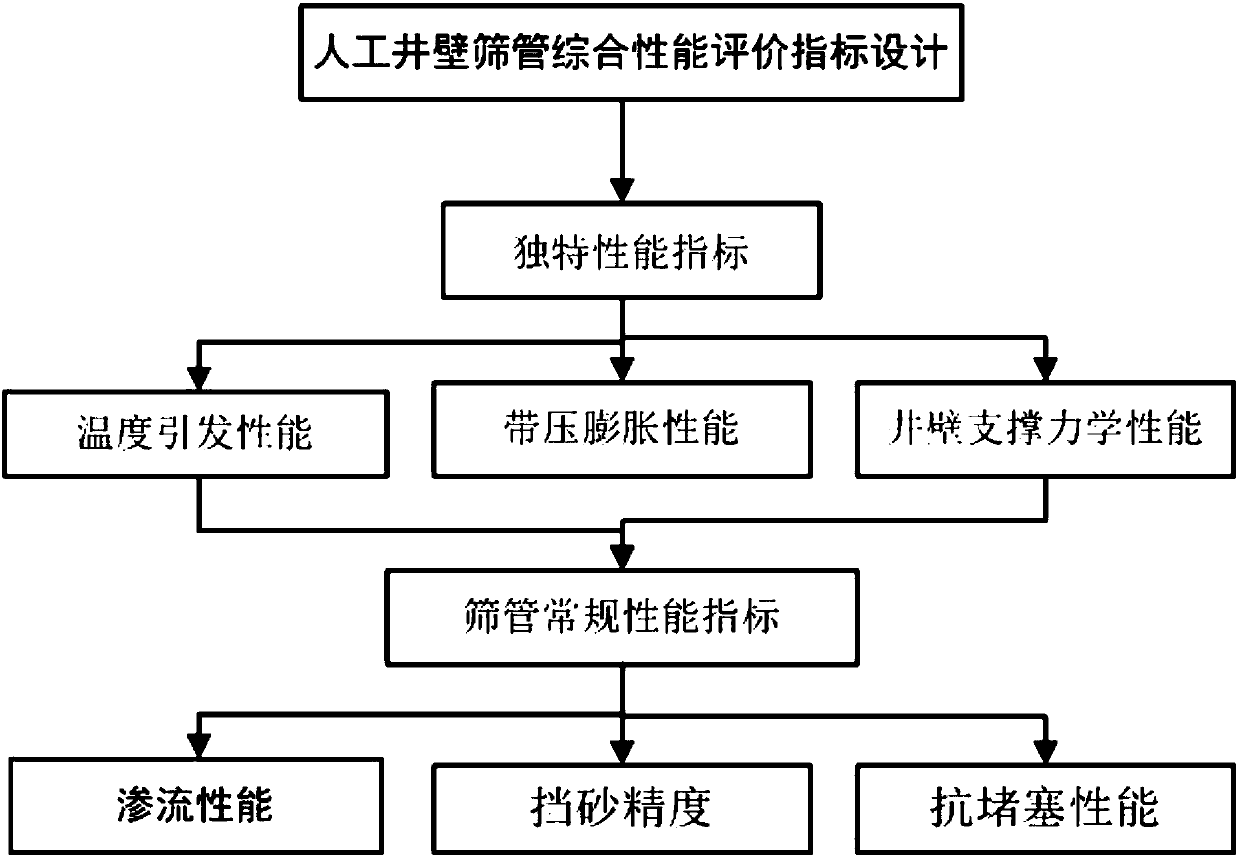

[0057] The experimental device in the present invention can simulate the downhole working principle and action of the expandable screen, and can detect the combinati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com