Method for constructing ventilating permeable ecological concrete water-storage side slope

An ecological concrete and construction method technology, applied in the direction of coastline protection, etc., can solve the problems of large surplus height of embankment body, slope washing and excavation, erosion and erosion, etc., and achieve the effect of reducing surplus height, improving filter performance and reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

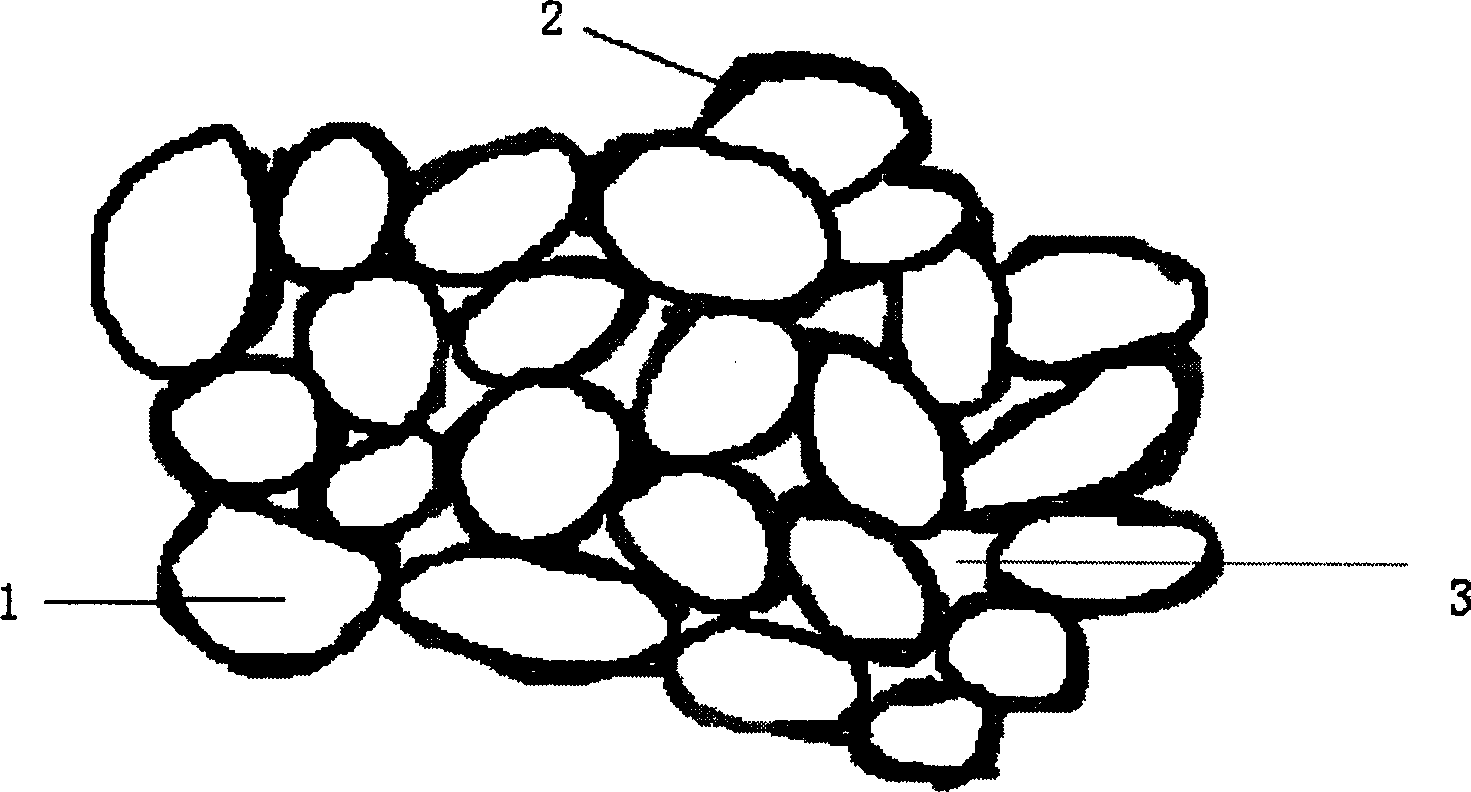

[0020] Such as figure 1 As shown, the ventilating and water-permeable concrete structure obtained by the method of the present invention includes granular aggregates 1 , cement hydrate 2 bonding the granular aggregates, and continuous voids 3 between the granular aggregates.

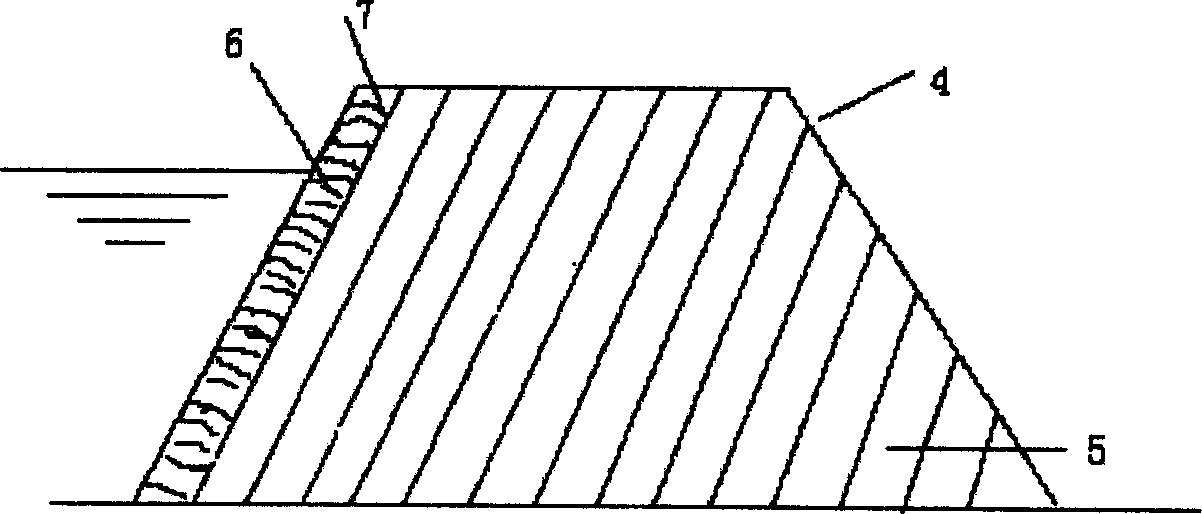

[0021] Such as figure 2 Shown, with the storage side slope of the embankment 4 of the reservoir of the inventive method construction or river, its structure is made of filling soil material 5, ventilating and permeable concrete 6 on the trapezoidal section.

[0022] In addition, in order to make the air-permeable concrete have a better filter effect, fine sand can also be injected into the gaps of the hardened air-permeable concrete to form a whole. In this case, the interstitial channels will not be blocked to reduce the permeability coefficient. Compared with existing techniques such as using stone materials, its construction is simple and the construction period is short, and it is easy to maintain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com