Efficient washing equipment applicable to thin-diameter thin-wall long metal tubes

A long tube and metal technology, which is applied in the field of high-efficiency washing equipment, can solve the problems of inconvenient draining and drying, time-consuming and labor-intensive cleaning, and incomplete cleaning, so as to improve the ultrasonic cavitation effect, improve the cleaning effect, and reduce the cleaning difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

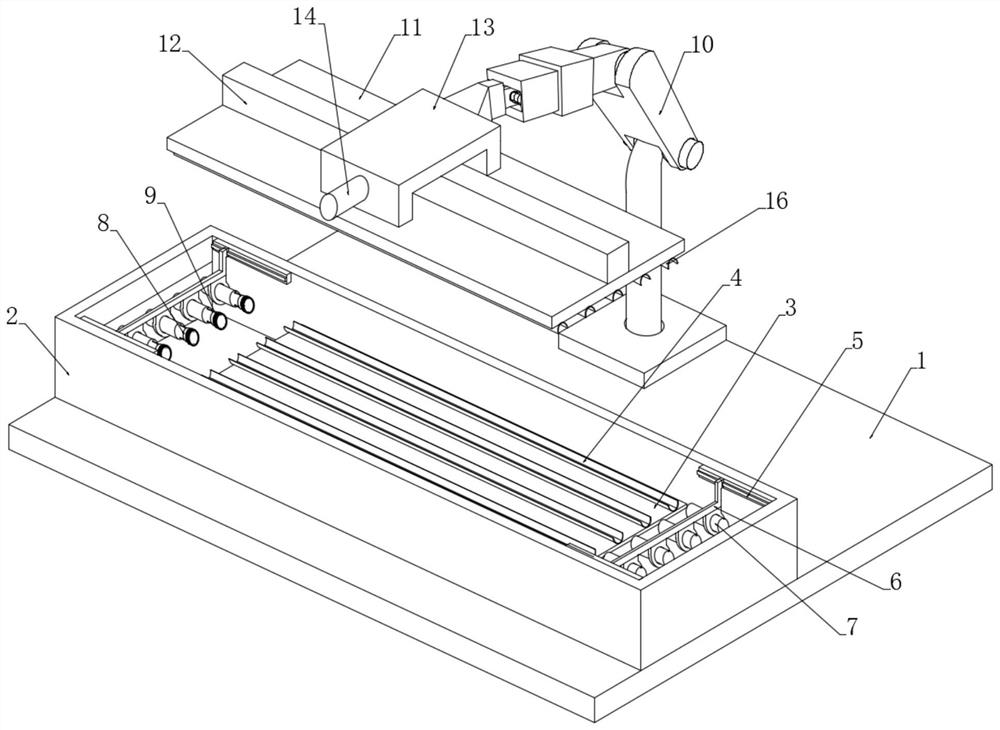

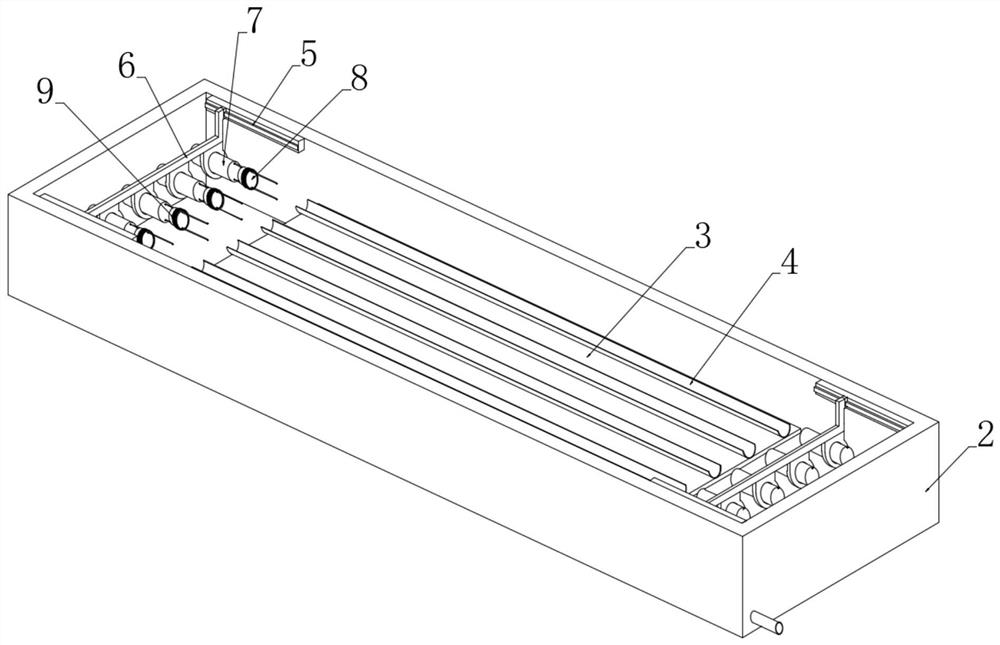

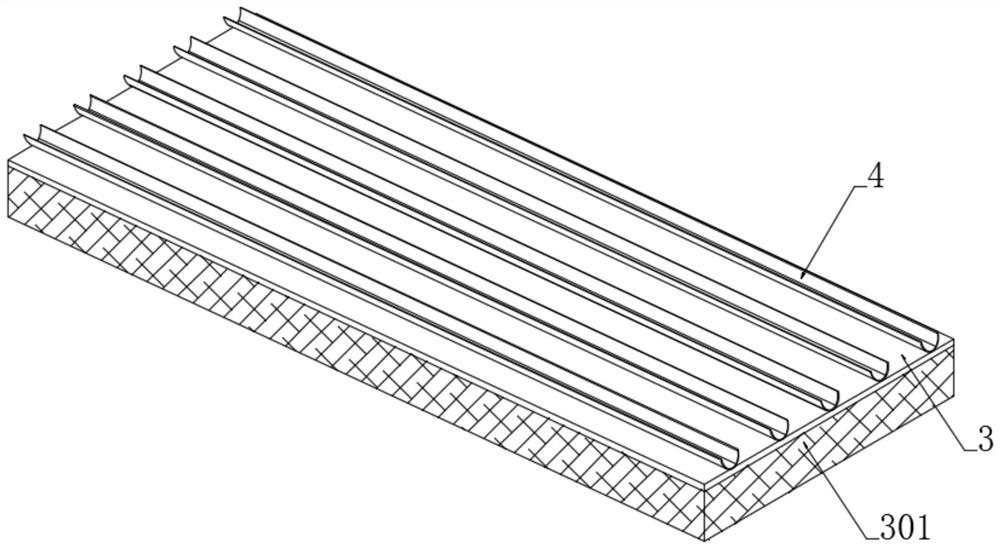

[0038] see Figure 1-3 , a high-efficiency scrubbing equipment suitable for thin-diameter and thin-walled metal long pipes, including a cleaning box 2 fixedly installed on the operating table 1, a metal long tube positioning plate 3 is fixedly installed on the inner middle of the cleaning box 2, and the metal long tube The upper end of the positioning plate 3 is horizontally provided with a plurality of evenly distributed arc-shaped long tube limit sleeves 4, and the inner end side walls of the multiple arc-shaped long tube limit sleeves 4 are embedded with a first electromagnet, and the multiple After the long tube is placed in the arc-shaped long tube limit sleeve 4, the first electromagnet is energized, so that the long tube can be firmly fixed in the arc-shaped long tube limit sleeve 4, effectively preventing the long tube from shifting during scrubbing .

[0039] Specifically, the cleaning box 2 is an ultrasonic cleaning box, and the bottom end of the metal long tube pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com