Method for controlling spontaneous combustion of underground coal and developing and utilizing

A coal spontaneous combustion and ground control technology, applied in underground mining, ground mining, earth drilling and mining, etc., can solve the problems of ineffectiveness, waste of resources, pollution, etc., and achieve the effects of slowing down the spread, saving money, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

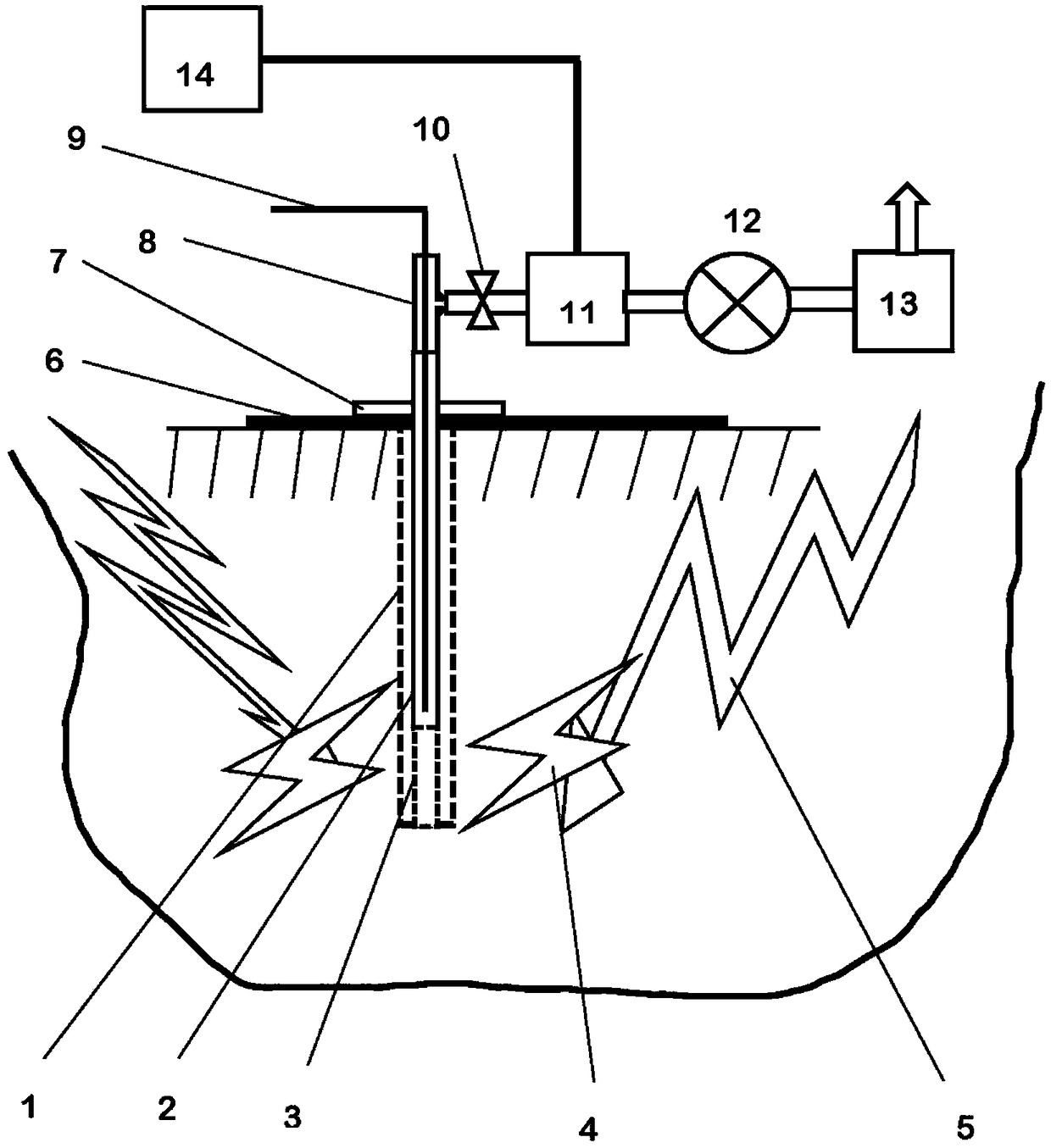

[0046] Embodiment 1 controls ground fire and utilizes the method for its thermal energy

[0047] Principle: artificially intervene in the combustion conditions of the ground fire 4, control the air entering the passage underground to participate in the combustion of the ground fire 4, and form a certain negative pressure in the high-temperature area of the ground fire by the induced draft fan 12, thereby collecting the high-temperature smoke of the ground fire 4, Through the screen pipe 3, it is pumped to the ground by the sleeve pipe 2, and after exchanging heat with the heat exchanger 11, the heat energy of the ground fire 4 can be utilized through the waste heat utilization device 14, and the flue gas of the ground fire 4 can be treated by the environmental protection treatment device 13 Environmental protection treatment to achieve pollution control.

Embodiment approach

[0049] 1. Carry out geological exploration and ground temperature surveys in the area where ground fires occur, according to the geological structure and distribution of ground fires, as well as the conditions of coal seams that may participate in fires, ground topographical conditions, surface soil permeability and surface cracks, etc. Factors, divide the Earthfire 4 area into several blocks.

[0050] 2. At a reliable position in each block, one or more boreholes are drilled in the direction of the ground fire 4, and the depth reaches near the combustion center of the ground fire 4 or goes deep into the burning coal seam to form a production well 1.

[0051] 3. Place the screen 3 in each borehole of the production well 1. The screen 3 is made of a pipe (the material is required to be able to withstand high temperatures above 900°C) with an outer diameter smaller than the inner diameter of the production well (subject to being able to be placed in the well smoothly). Drill air...

Embodiment 2

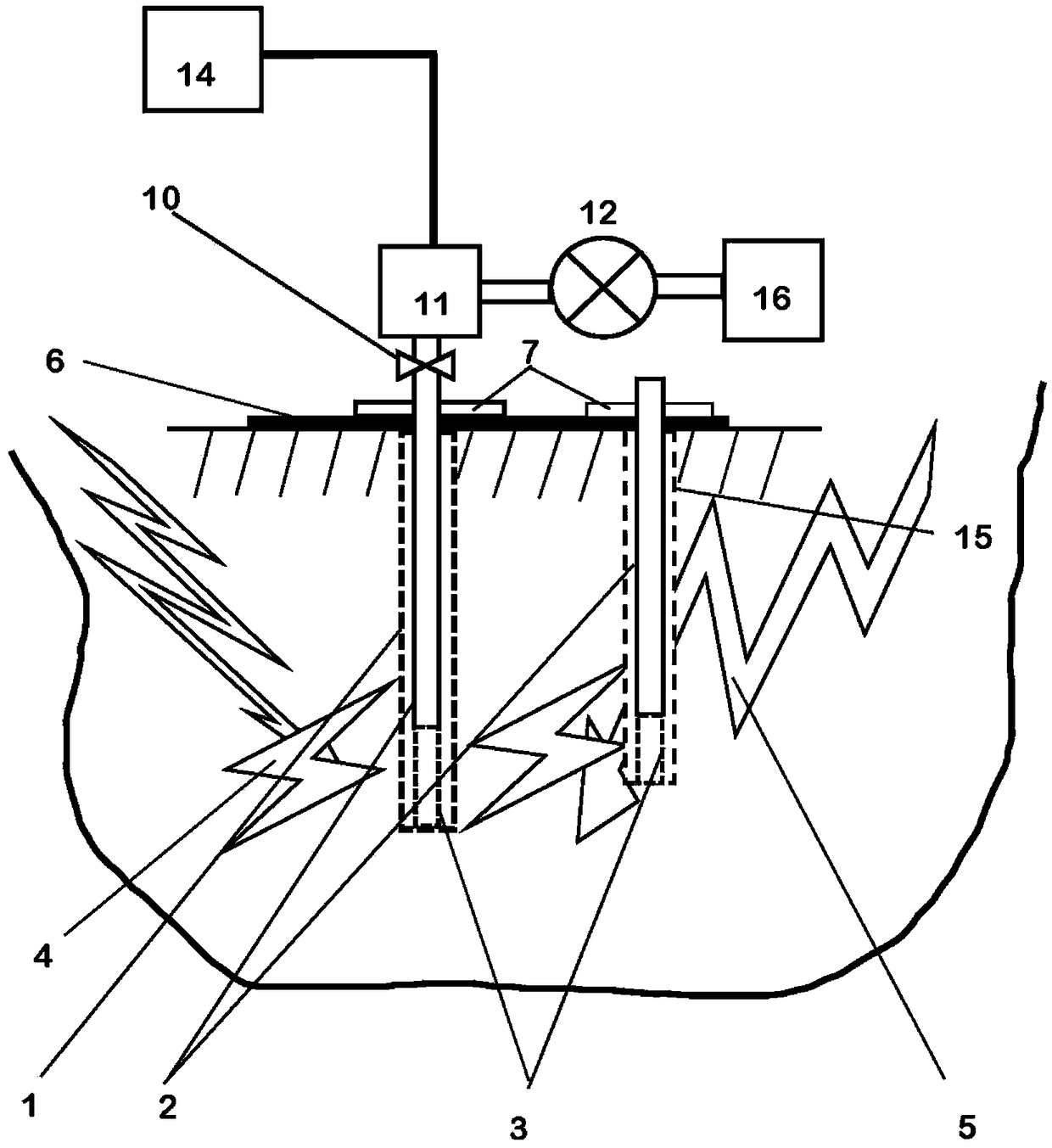

[0060] Embodiment 2 The method of controlling ground fire and adjusting flue gas components to produce syngas

[0061] Principle: After investigating the combustion conditions of the ground fire 4, man-made intervenes in its combustion conditions, controls the passage of air entering the ground to participate in the combustion of the ground fire 4, and drills one or more drill holes to the appropriate position of the ground fire 4 combustion bed to form an auxiliary Well 15, through the auxiliary well 15, transports water or steam and other tempered gases to the combustion bed of the ground fire 4 to participate in combustion, changes the carbon-hydrogen ratio of the flue gas components of the ground fire 4, and produces syngas that meets the needs of chemical production. The induced draft fan 12 is pumped to the ground through the screen pipe 3 and the sleeve pipe 2, and after exchanging heat with the heat exchanger 11, the heat energy is utilized through the waste heat utiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com