Re-use agent for polymer after driving and injecting method thereof

A technology of polymers and fixatives, applied in drilling compositions, chemical instruments and methods, earthwork drilling and production, etc., can solve near-wellbore blockage, influence of deep profile control, influence of fixative injection and deep profile control Function and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

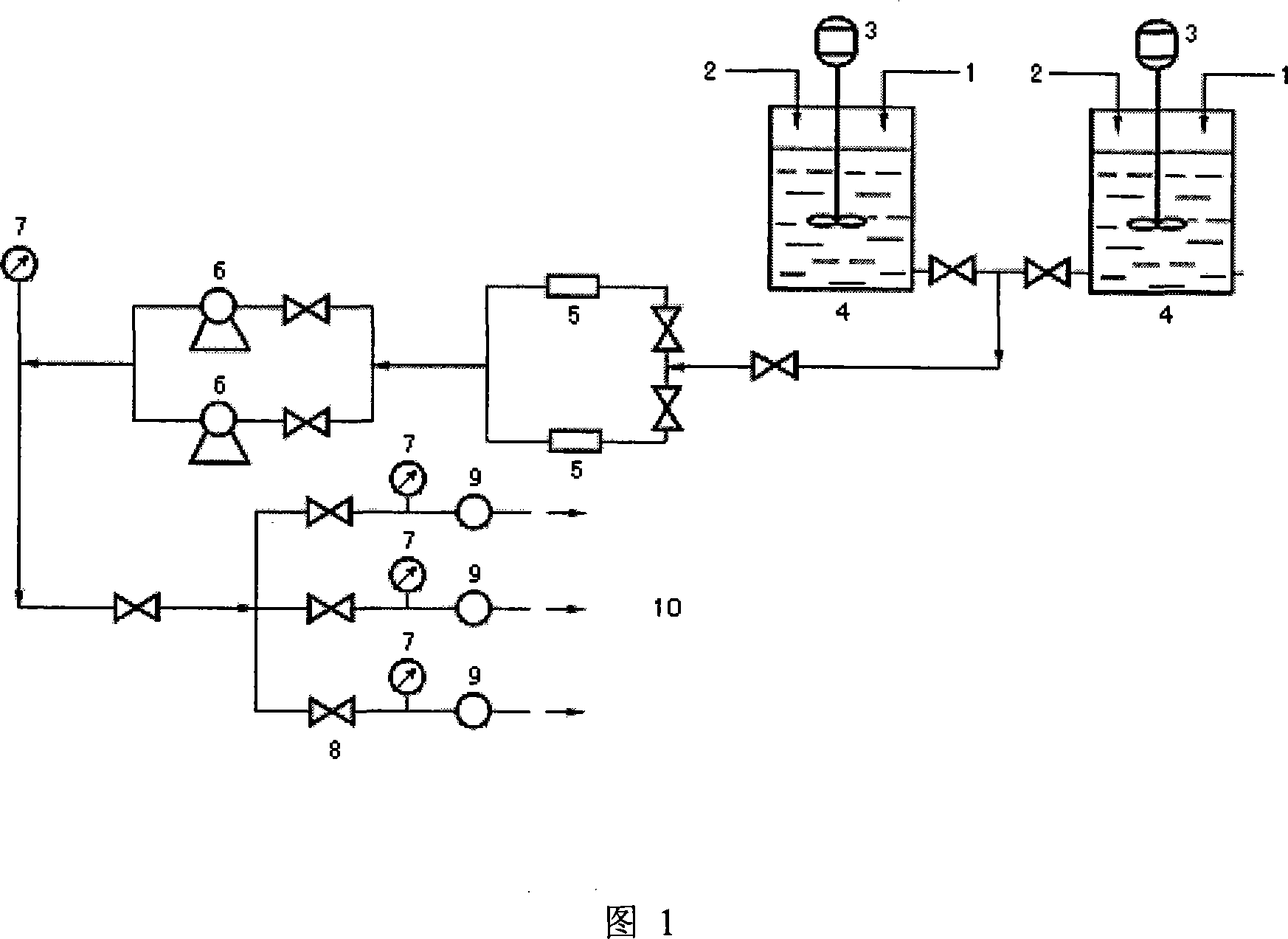

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the examples.

[0013] Since the fixative is suitable for formation residual polymer mass concentration exceeding 800mg·L -1 Formation, while the flocculant can be in the polymer mass concentration of 200 ~ 800mg L -1 Flocculation can still be performed within the range, so the fixative should be injected first, followed by the flocculant.

[0014] Under normal circumstances, the total amount of fixative required to penetrate the formation with a thickness of 1m is 40-80m 3 , the volume ratio of the two working fluids is (0.8-1.2): 1. The amount of flocculant required to penetrate the formation with a thickness of 1m is 140-180m 3 .

[0015] The volume of spacer fluid injected between the two working fluids is determined by the following formula:

[0016] V = π ( R 2 2 - ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com