Denitrification filter combined packing and application thereof

A denitrification filter and combined packing technology, which is applied in the field of nitrogen-containing domestic sewage and industrial wastewater treatment, can solve the problems of no accumulation of nitrite nitrogen and high pH, so as to avoid sludge bulking and produce less sludge , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

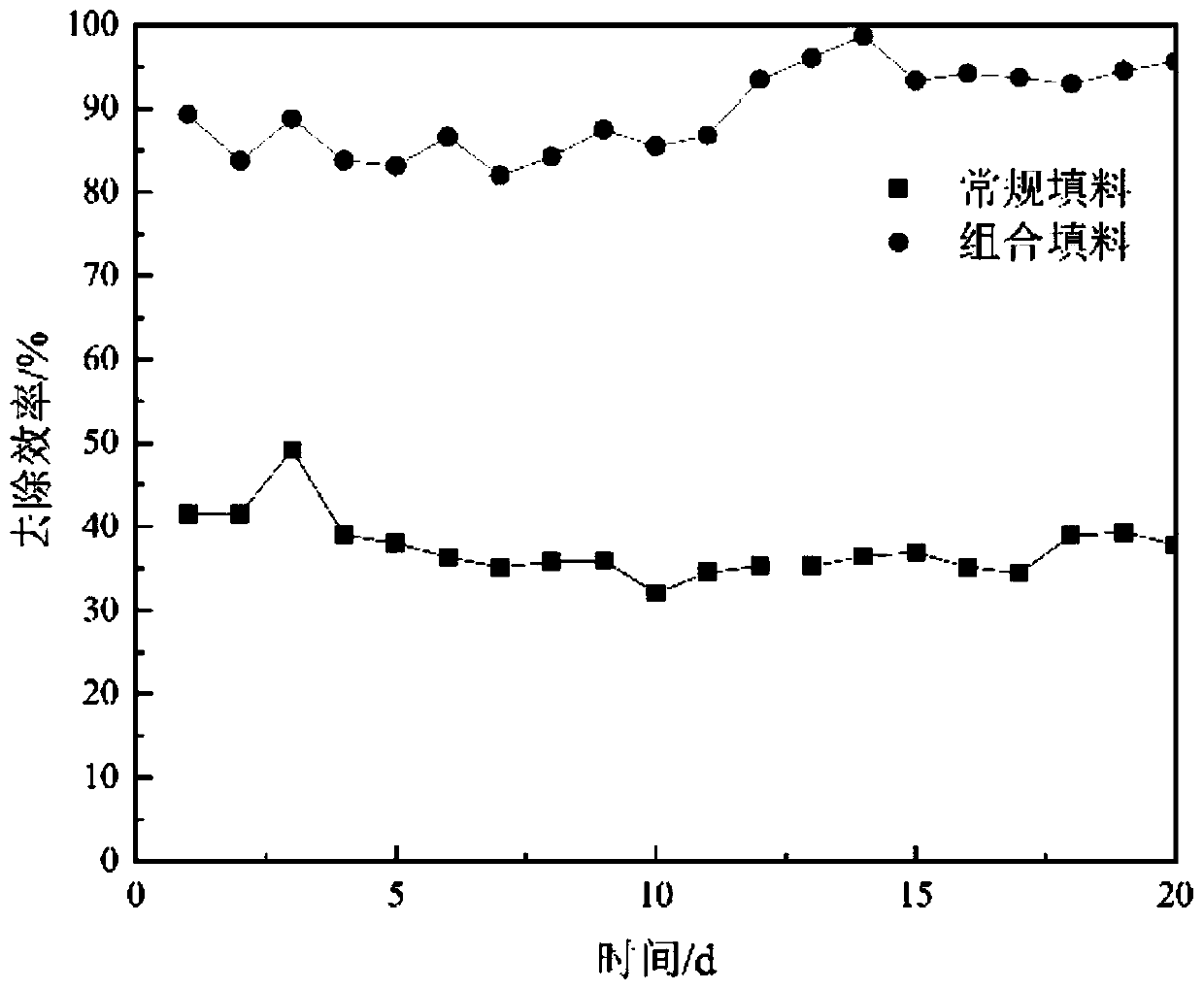

[0060] The low-carbon source in embodiment 1 adds the combined packing of high-efficiency denitrification filter, and is made up of iron-carbon filler, sulfur, porous material, wherein the mass ratio of each component of iron-carbon filler is reduced iron powder 45%, activated carbon 15% , copper powder 10%, calcium sulfate 20%, ammonium bicarbonate 5%, sodium bicarbonate 5%.

[0061] (1) Blend and mix the reduced iron powder, activated carbon, copper powder, calcium sulfate, ammonium bicarbonate and sodium bicarbonate, slowly add water with 20% of the raw material mass and mix to form a viscous mixture;

[0062] (2) Fill the mixture obtained in step (1) into a spherical mold with an inner diameter of 9mm, and dry it in a vacuum oven at 60°C for 8 hours;

[0063] (3) The product obtained after vacuum drying in step (2) was calcined at 400° C. for 2 hours under high-purity nitrogen to make iron-carbon filler.

[0064] (4) Static film-hanging stage: the combined filler is the i...

Embodiment 2

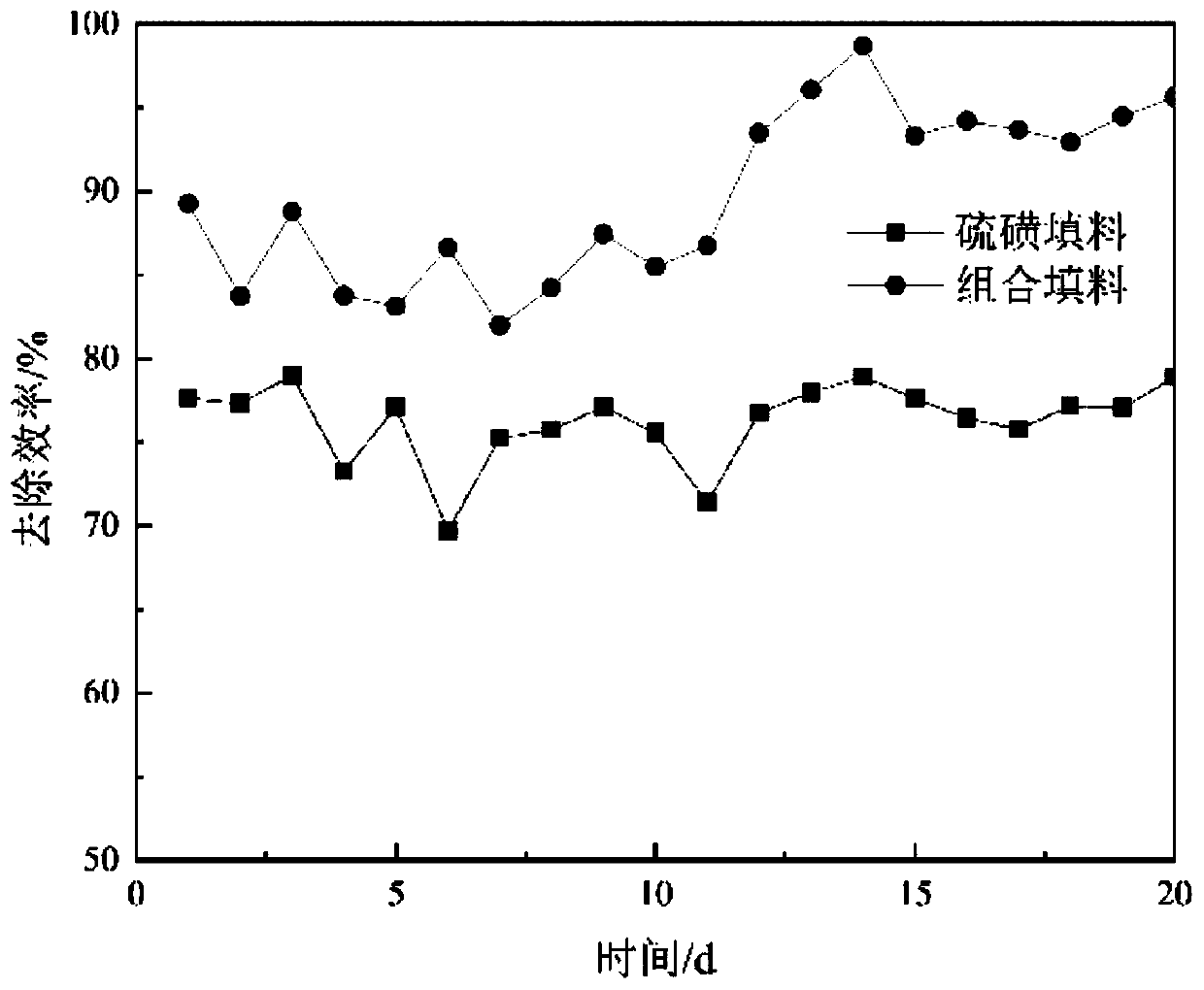

[0068] The low-carbon source in Example 2 is added with the combined filler of the high-efficiency denitrification filter. The combined filler in the reactor is iron-carbon filler, sulfur, oyster shell and volcanic rock from bottom to top, and its volume ratio is: iron-carbon filler: Sulfur: oyster shell: volcanic rock = 1:1:1:1, the combined filler accounts for 50% of the reactor volume, and the preparation method of the iron-carbon filler is the same as in Example 1.

[0069] Through the same static film-hanging stage as in Example 1, after the continuous culture stage and the stable operation stage, the average influent nitrate nitrogen concentration is 30 ± 5mg / L, C / N=1.5-2, and the influent dissolved oxygen DO= Under the conditions of 1.0-2.0mg / L and hydraulic retention time HRT=4h, the average concentration of nitrate nitrogen in the effluent is 1.8-3mg / L, the removal rate of nitrate nitrogen is 90-94%, and there is no ammonia nitrogen and nitrite nitrogen accumulation, ...

Embodiment 3

[0071] The low-carbon source in Example 3 is added with the combined filler of the high-efficiency denitrification filter. The combined filler in the reactor is iron-carbon filler, sulfur, medical stone and volcanic rock from bottom to top, and its volume ratio is: iron-carbon filler : sulfur: medical stone: volcanic rock=1:1:1:1, the combined filler accounts for 50% of the reactor volume, wherein the preparation method of the iron-carbon filler is the same as in Example 1.

[0072] Through the same static film-hanging stage as in Example 1, after the continuous culture stage and the stable operation stage, the average influent nitrate nitrogen concentration is 30 ± 5mg / L, C / N=1.5-2, and the influent dissolved oxygen DO= Under the conditions of 1.0-2.0mg / L and hydraulic retention time HRT=4h, the average concentration of nitrate nitrogen in the effluent is 2.3-3.2mg / L, the removal rate of nitrate nitrogen is 89-92%, and there is no ammonia nitrogen and nitrite The accumulation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com