Compact anti-cracking waterproof agent capable of inhibiting early cracking of concrete and preparation method of dense anti-cracking waterproof agent

A technology of anti-cracking and waterproofing agent and concrete, which is applied in the field of building materials, can solve the problems of inability to improve early cracking and poor concrete impermeability, and achieve the goal of improving impermeability and waterproof performance, increasing ultimate tensile strength, and enhancing impermeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

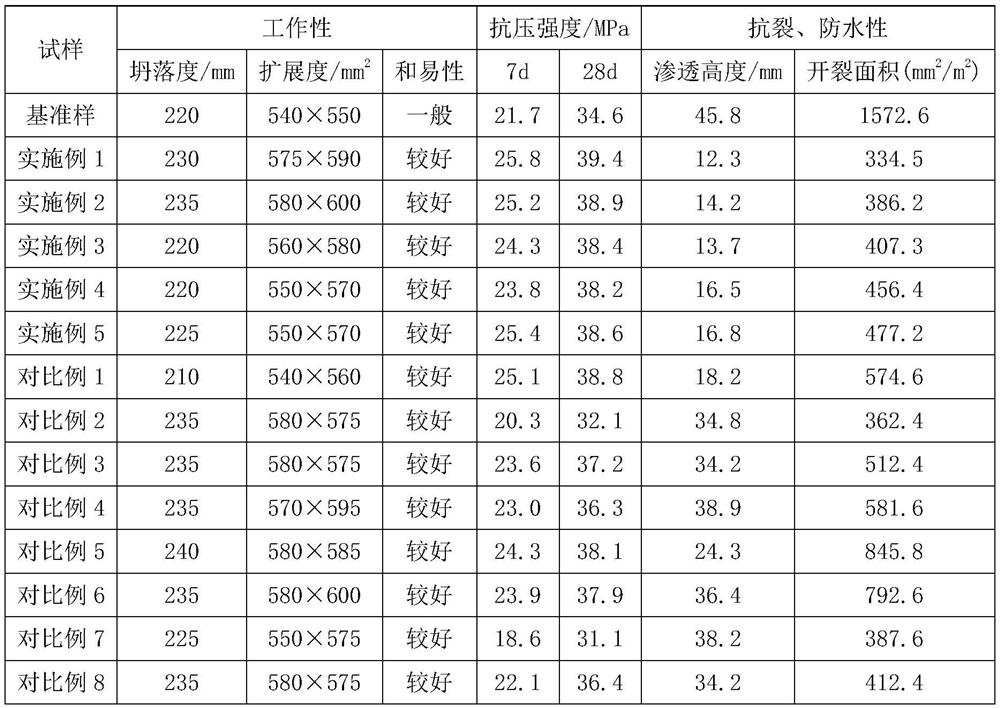

Examples

Embodiment 1-3 and comparative example 1、2

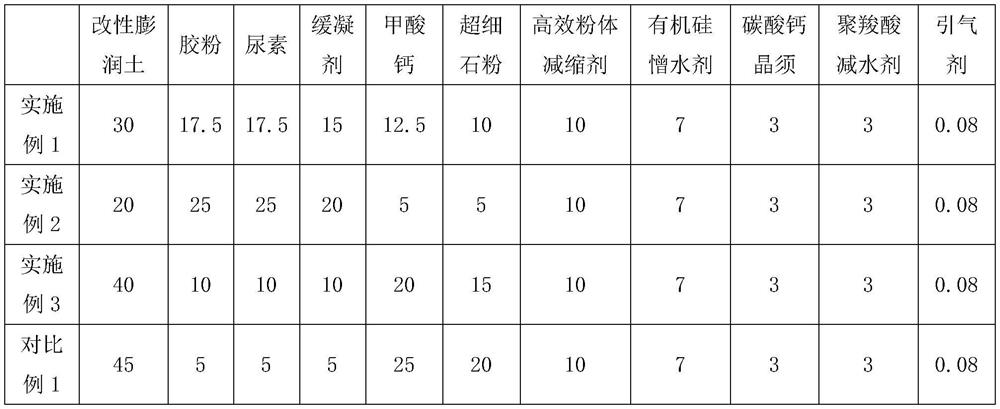

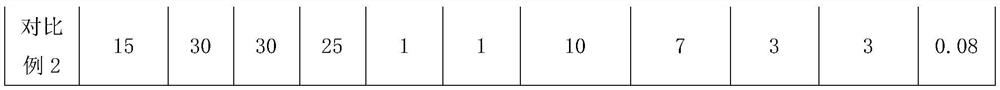

[0027] Examples 1-3 and Comparative Examples 1 and 2 provide early-stage concrete cracking-inhibiting compact anti-cracking waterproofing agents, and their raw material compositions are shown in Table 1 below in parts by weight.

[0028] The compact anti-cracking waterproofing agent raw material of table 1 embodiment 1-3 and comparative example 1,2, unit: part

[0029]

[0030]

Embodiment 4

[0032] The early cracking-inhibiting concrete anti-crack waterproofing agent provided in this example has the same raw material composition as in Example 1, the difference is that the preparation method of the modified bentonite used is: first mix sodium-based bentonite with 1mol / L Fe 2 (SO 4 ) 3 The solution is mixed according to the mass ratio of 1:10, stirred at 1000r / min for 1h until the mixture is uniform, and then aged at room temperature for 24h; then the aged slurry is filtered at room temperature, washed with water, dried and cooled at 105°C, and then Grinding treatment, and finally passing the powder through a 0.075um standard sieve to obtain modified bentonite.

Embodiment 5

[0034] The early cracking-inhibiting concrete anti-crack waterproofing agent provided in this example has the same raw material composition as in Example 1, the difference is that the preparation method of the modified bentonite used is: first mix sodium-based bentonite with 1mol / L Fe 2 (SO 4 ) 3 The solution is mixed according to the mass ratio of 1:20, stirred at 1000r / min for 1h until the mixture is uniform, and then aged at room temperature for 24h; then the aged slurry is filtered at room temperature, washed with water, dried and cooled at 105°C, and then Grinding treatment, and finally passing the powder through a 0.075um standard sieve to obtain modified bentonite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com