High-strength and high-conductivity rare-earth chromium-zirconium-copper spring contact finger and manufacturing method thereof

A spring-finger, high-conductivity technology, used in contacts, circuits, electrical switches, etc., can solve the problems of environmental pollution, low elasticity, easy deformation, etc., and achieve excellent comprehensive performance, small burning loss, and good resilience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

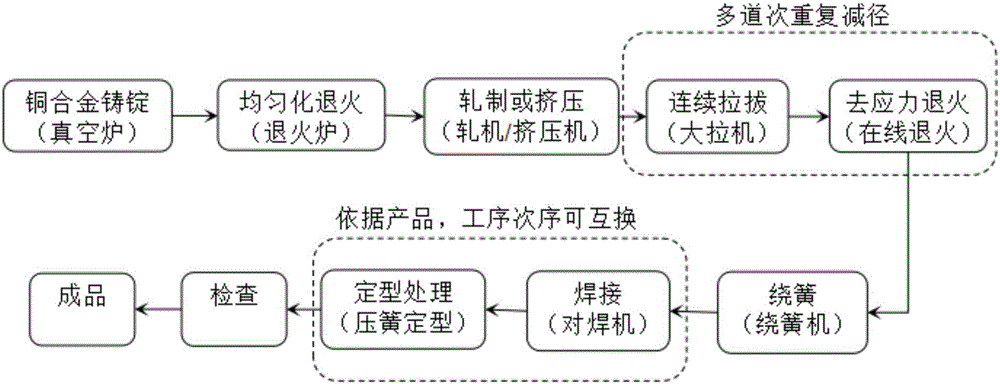

Method used

Image

Examples

Embodiment 1

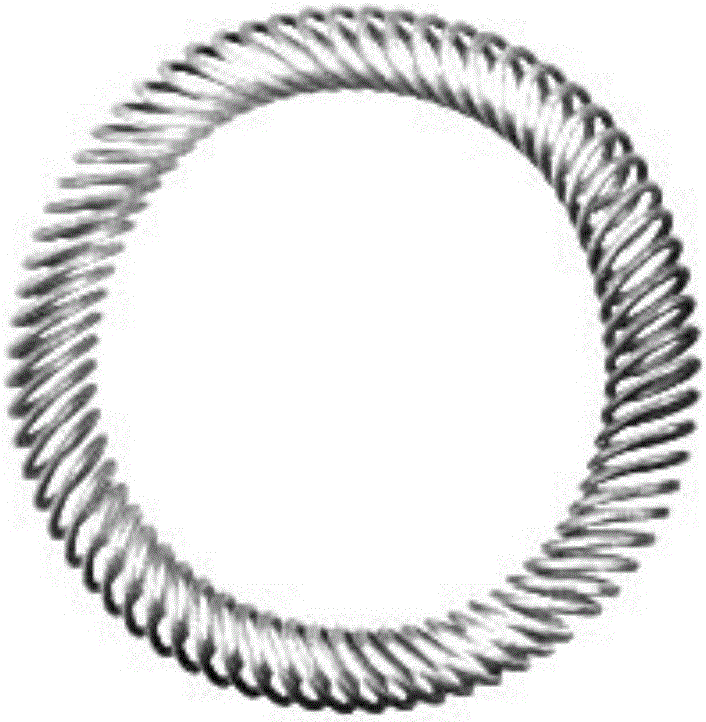

[0024] Metal copper (99.95%), metal zirconium (99.9%), metal chromium (99.9%) and industrial rare earth materials (cerium-rich rare earth silicon magnesium), the alloying ratio is: chromium 8%, zirconium 0.1%, rare earth 3 %, copper 88.9%, followed by vacuum smelting (vacuum degree 6.67×10 -2 Pa~6.67×10 -2 Pa; add copper into the furnace to be melted into copper water, add metal chromium wrapped in copper skin, and keep the furnace at 1330°C; secondly, metal zirconium wrapped in copper skin, keep the temperature of the furnace at 1310°C, keep warm and melt; finally add industrial rare earth materials, keep warm Casting after 20 minutes), homogenization annealing (temperature 900°C, time 1h), ingot extrusion billet opening (extrusion bar size Φ18mm), multi-pass continuous drawing and intermediate stress relief annealing (temperature 450°C), The main processes such as wire winding spring, fixed-length compression spring, and contact finger butt welding are used to make the fini...

Embodiment 2

[0027] Metal copper (99.95%), metal zirconium (99.9%), metal chromium (99.9%) and industrial rare earth materials (cerium-rich rare earth silicon magnesium), the alloying ratio is: chromium 10%, zirconium 0.2%, rare earth 6 %, copper 83.8%, followed by vacuum smelting (vacuum degree 6.67×10 -2 Pa~6.67×10 -2 Pa; add copper to the furnace to be melted into copper water, add metal chromium wrapped in copper skin, and keep the furnace at 1430 °C; secondly, metal zirconium wrapped in copper skin, keep the temperature of the furnace at 1410 °C, keep warm and melt; finally add industrial rare earth materials, keep warm Casting after 5 minutes), homogenization annealing (temperature 980°C, time 2h), ingot extrusion billet opening (extrusion bar size Φ30mm), multi-pass continuous drawing and intermediate stress relief annealing (temperature 580°C), The main processes such as wire winding spring, fixed-length compression spring, and contact finger butt welding are used to make the fini...

Embodiment 3

[0030] Metal copper (99.95%), metal zirconium (99.9%), metal chromium (99.9%) and industrial rare earth materials (cerium-rich rare earth silicon magnesium), the alloying ratio is: chromium 15%, zirconium 0.5%, rare earth 8 %, copper 76.5%, followed by vacuum smelting (vacuum degree 6.67×10 -2 Pa~6.67×10 -2 Pa; add copper to the furnace to be melted into copper water, add metal chromium wrapped in copper skin, and keep the furnace at 1400 °C; secondly, metal zirconium wrapped in copper skin, keep the temperature of the furnace at 1400 °C, keep warm and melt; finally add industrial rare earth materials, keep warm Casting after 5-20 minutes), homogenization annealing (temperature 950°C, time 1h-2h), ingot extrusion billet opening (extrusion bar size Φ18-Φ30mm), multi-pass continuous drawing and intermediate stress relief annealing (Temperature 500 ℃), wire winding spring, fixed-length compression spring, contact finger butt welding and other main processes to make the finished ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ultimate tensile strength | aaaaa | aaaaa |

| Ultimate tensile strength | aaaaa | aaaaa |

| Ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com