Anti-seismic reinforcing method for bridge transverse check block

A stopper and transverse technology, which is applied in the field of seismic reinforcement of bridge transverse stoppers, can solve problems such as weak lateral restraint ability of stoppers, and achieve the effects of short construction period, reduced damage, and high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

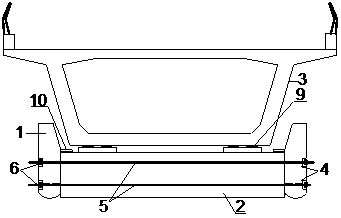

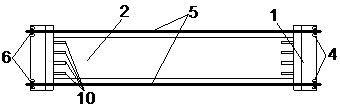

[0042] like Figure 4 , Figure 5 , Figure 9 Shown, a kind of anti-seismic strengthening method of bridge transverse stopper, in this embodiment, the method for quick anti-seismic reinforcement and repair after bridge transverse stopper damage. It is suitable for damaged stoppers 7 where common failures such as oblique shear failure, bending shear failure, and flat shear failure occur.

[0043] The seismic reinforcement method for the transverse block of the bridge includes the following steps:

[0044] S1, reset the laterally displaced main girder 3 and replace the bridge support 9

[0045] S2, cutting off the damaged transverse block 7 on the existing cover beam 2, and performing overlay treatment on the cut surface;

[0046] S3, design and prefabricate a new anti-seismic block assembly 1, and hoist it to the two ends of the existing cover beam 2 for positioning;

[0047] S4, the splicing of the new anti-seismic block assembly 1 and the existing cover beam 2 is realize...

Embodiment 2

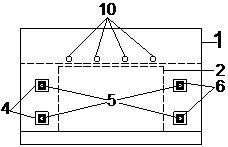

[0067] like Image 6 , Figure 7 , Figure 9 As shown, an aseismic reinforcement method for a bridge transverse block, in this embodiment, is suitable for the case where the designed weak block 8 is too weak in lateral restraint capacity.

[0068] An anti-seismic reinforcement method for a bridge transverse stopper is characterized in that it comprises the following steps:

[0069] S1, check whether the main beam 3 is displaced and whether the support 9 is damaged. If the main beam is displaced, reset the main beam 3 and replace it.

[0070] Change the support 9;

[0071] S2, cutting off the weakly designed transverse stopper 8 on the cover beam 2, and performing overlay treatment on the cut surface;

[0072] S3, design and manufacture a new anti-seismic block assembly 1, and hoist it to the two ends of the existing cover beam 2 for positioning;

[0073] S4, realizing the splicing of the new anti-seismic block assembly 1 and the existing cover beam 2 by stretching the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com