Anti-corrosion self-cleaning composite coating as well as preparation method and application thereof

A composite coating and self-cleaning technology, used in anti-corrosion coatings, coatings, anti-fouling/underwater coatings, etc. Excellent chemical resistance, enhanced stability, increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

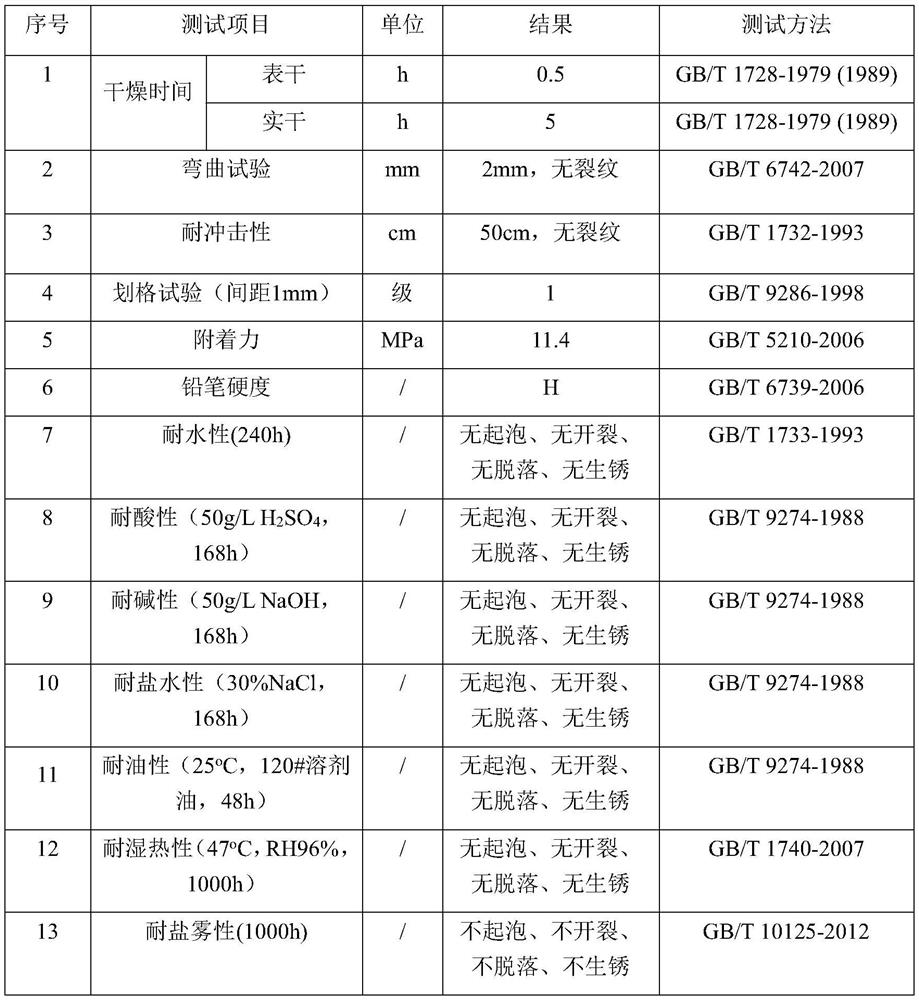

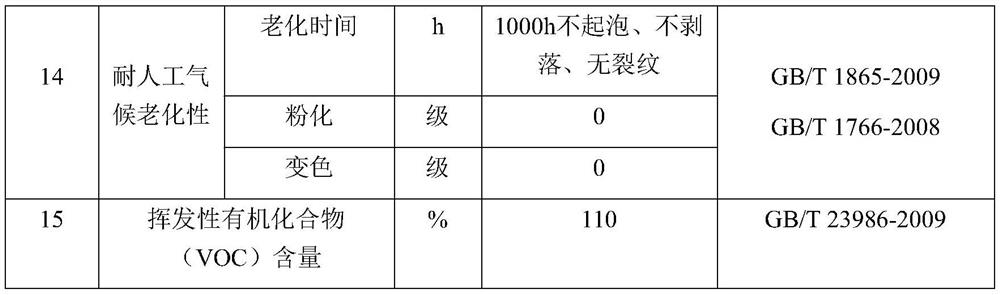

Examples

Embodiment 1

[0042] This embodiment provides an anti-corrosion self-cleaning composite coating, which includes an epoxy resin layer and a polyurethane layer in contact. in,

[0043] The epoxy resin composition is prepared from the following raw materials:

[0044] The first component includes the following raw material components in parts by weight: 40 parts of water-based epoxy emulsion, 12 parts of deionized water, 12 parts of aluminum corrosion inhibitor, 19 parts of filler, 4 parts of coupling agent, 1.5 parts of wetting and dispersing agent , 5 parts of defoamer, 1.5 parts of anti-settling dispersant, 1.5 parts of thickener, 1.5 parts of film-forming aid, 1 part of leveling agent, and 1 part of adhesion promoter;

[0045] The second component includes the following components by weight: 65 parts of water-based epoxy curing agent, 33 parts of deionized water and 2 parts of reactive diluent.

[0046] Among them, the ratio of the epoxy equivalent of the water-based epoxy emulsion to th...

Embodiment 2

[0066] This embodiment provides an anti-corrosion self-cleaning composite coating, which includes an epoxy resin layer and a polyurethane layer in contact. in,

[0067] The epoxy resin composition is prepared from the following raw materials:

[0068] The first component, including the following raw material components by weight: 25 parts of water-based epoxy emulsion, 15 parts of deionized water, 15 parts of aluminum corrosion inhibitor, 25 parts of filler, 5 parts of coupling agent, 2 parts of wetting and dispersing agent , 5 parts of defoamer, 2 parts of anti-settling dispersant, 2 parts of thickener, 2 parts of film-forming aid, 1 part of leveling agent, 1 part of adhesion promoter;

[0069] The second component includes the following components by weight: 65 parts of water-based epoxy curing agent, 33 parts of deionized water and 2 parts of reactive diluent.

[0070] Among them, the ratio of the epoxy equivalent of the water-based epoxy emulsion to the active hydrogen e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com