Organic silicon modified epoxy composite resin with fluorescence characteristics

A composite resin, fluorescent technology, applied in luminescent materials, luminescent coatings, coatings, etc., can solve the problems of poor stress cracking resistance, poor heat resistance, low impact resistance, etc., and achieve low surface energy and thermal stability. Good, low temperature and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

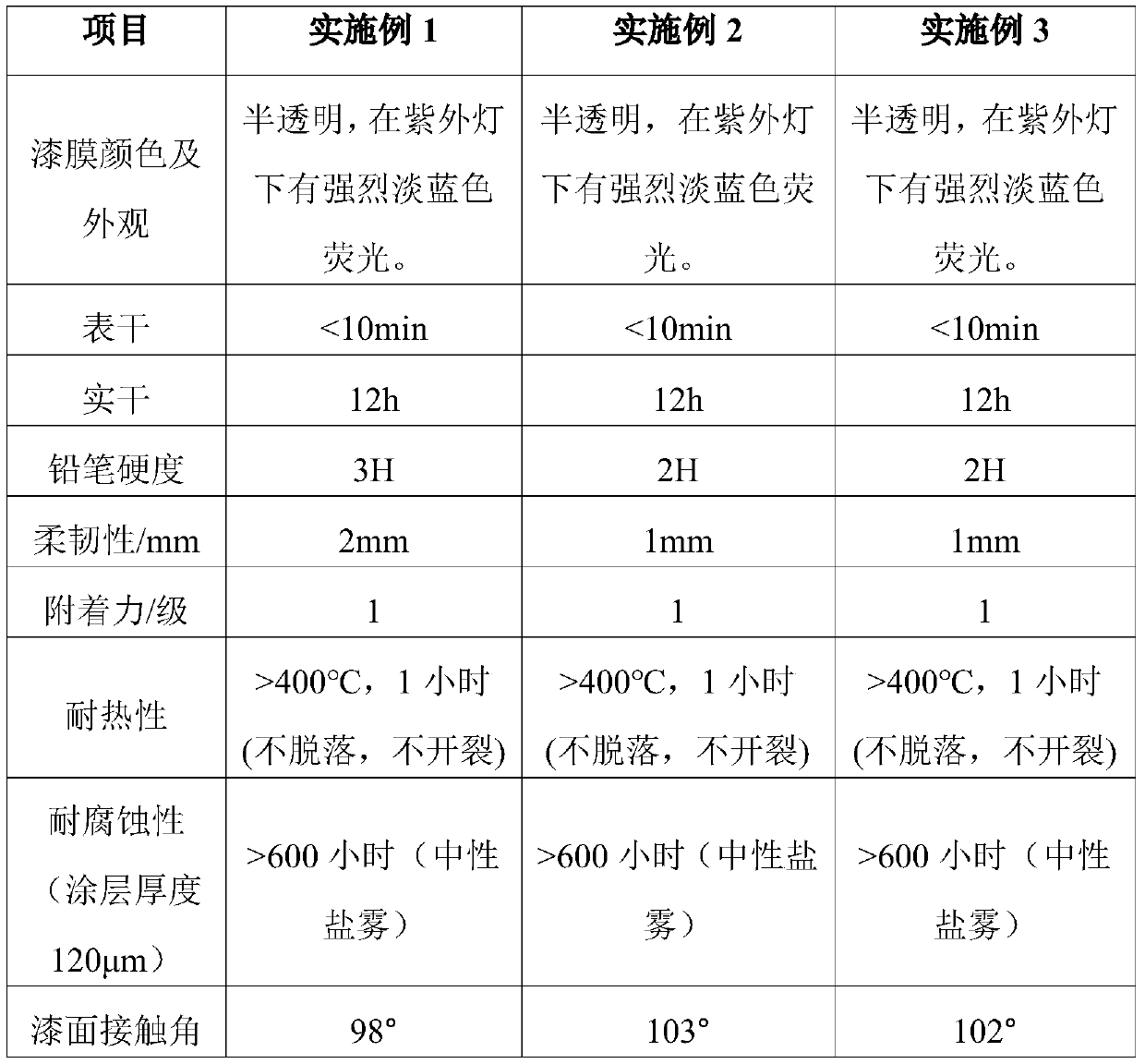

[0023] A silicone-modified epoxy composite resin with fluorescent properties, in terms of mass percentage, the silicone-modified epoxy composite resin is made of the following raw materials:

[0024] Amino silicone oil, 10wt%;

[0025] Four p-carboxytetraphenylethene, 1wt%;

[0026] Bisphenol A type epoxy resin, 89wt%;

[0027] Wherein, the organosilicon-modified epoxy composite resin is obtained through the following steps:

[0028] Step 1: Mix amino silicone oil and tetra-p-carboxytetraphenylethylene according to the designed amount to prepare a mixed solution, add dibutyltin dilaurate catalyst to the mixed solution, raise the temperature to 60°C, stir and heat for 24 hours to obtain the modified Intermediate of amino silicone oil;

[0029] Step 2, mix the modified amino silicone oil intermediate prepared in step 1 with the designed amount of bisphenol A epoxy resin, raise the temperature to 200°C, stir and heat for 12 hours, and cool to obtain the fluorescent characteris...

Embodiment 2

[0034] A silicone-modified epoxy composite resin with fluorescent properties, in terms of mass percentage, the silicone-modified epoxy composite resin is made of the following raw materials:

[0035] Amino silicone oil, 24wt%;

[0036] Four-p-carboxytetraphenylethene, 0.1wt%;

[0037] Bisphenol A type epoxy resin, 75.9wt%;

[0038] Wherein, the organosilicon-modified epoxy composite resin is obtained through the following steps:

[0039] Step 1: Mix amino silicone oil and tetra-p-carboxytetraphenylethylene according to the designed amount to prepare a mixed solution, add dibutyltin dilaurate catalyst to the mixed solution, raise the temperature to 75°C, stir and heat for 16 hours to obtain the modified Intermediate of amino silicone oil;

[0040] Step 2, mix the modified amino silicone oil intermediate prepared in step 1 with the designed amount of bisphenol A epoxy resin, raise the temperature to 180°C, stir and heat for 18 hours, and cool to obtain the fluorescent charact...

Embodiment 3

[0045] A silicone-modified epoxy composite resin with fluorescent properties, in terms of mass percentage, the silicone-modified epoxy composite resin is made of the following raw materials:

[0046] Amino silicone oil, 23wt%;

[0047] Four p-carboxytetraphenylethene, 2wt%;

[0048] Bisphenol A type epoxy resin, 75wt%;

[0049] Wherein, the organosilicon-modified epoxy composite resin is obtained through the following steps:

[0050] Step 1: Mix amino silicone oil and tetra-p-carboxytetraphenylethylene according to the designed amount to prepare a mixed solution, add dibutyltin dilaurate catalyst to the mixed solution, raise the temperature to 90°C, stir and heat for 4 hours to obtain the modified Intermediate of amino silicone oil;

[0051] Step 2, mix the modified amino silicone oil intermediate prepared in step 1 with the designed amount of bisphenol A epoxy resin, raise the temperature to 150°C, stir and heat for 24 hours, and cool to obtain the fluorescent characterist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com