A tensile aluminum alloy power cable

A technology for power cables and aluminum alloys, which is applied to power cables with shielding/conducting layers, insulated cables, cables, etc., which can solve the problems that cannot meet the needs of use, poor tensile strength and shielding performance, and can not generate resource loss, etc. problem, to achieve the effect of enhancing the protection hardness, improving the tensile strength and improving the performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

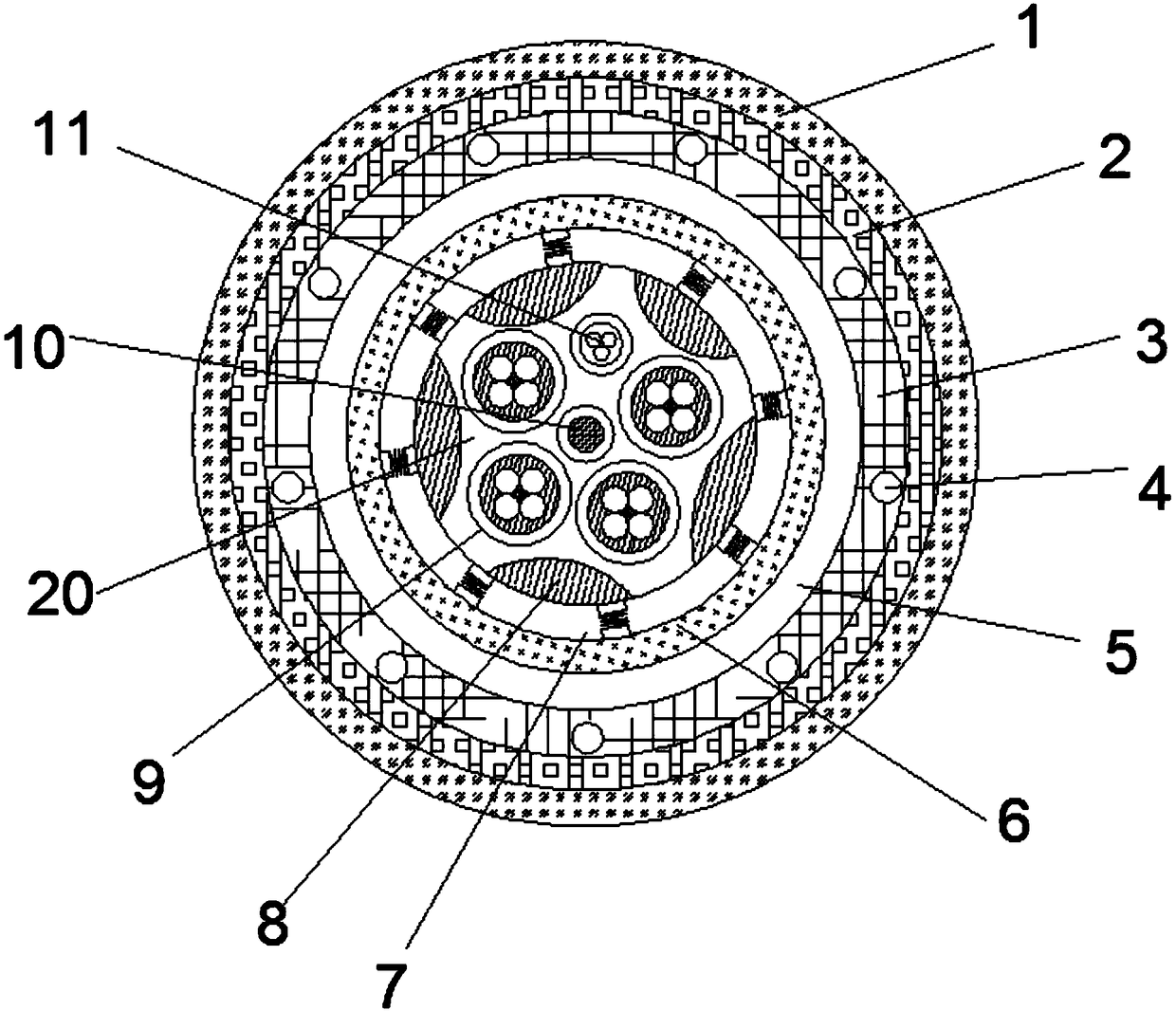

[0020] Such as Figure 1-Figure 3 As shown, a tensile aluminum alloy power cable proposed by the present invention includes an outer protective layer 1, a buffer layer 7 and a cable body 9, the inner side of the outer protective layer 1 is provided with a metal armor layer 2, and the inner side of the metal armor layer 2 is A reinforcing layer 3 is provided, and a plurality of reinforcing ribs 4 are arranged inside the reinforcing layer 3, a shielding layer 5 is arranged inside the reinforcing layer 3, an insulating layer 6 is arranged inside the shielding layer 5, and a buffer layer 7 is arranged inside the insulating layer 6;

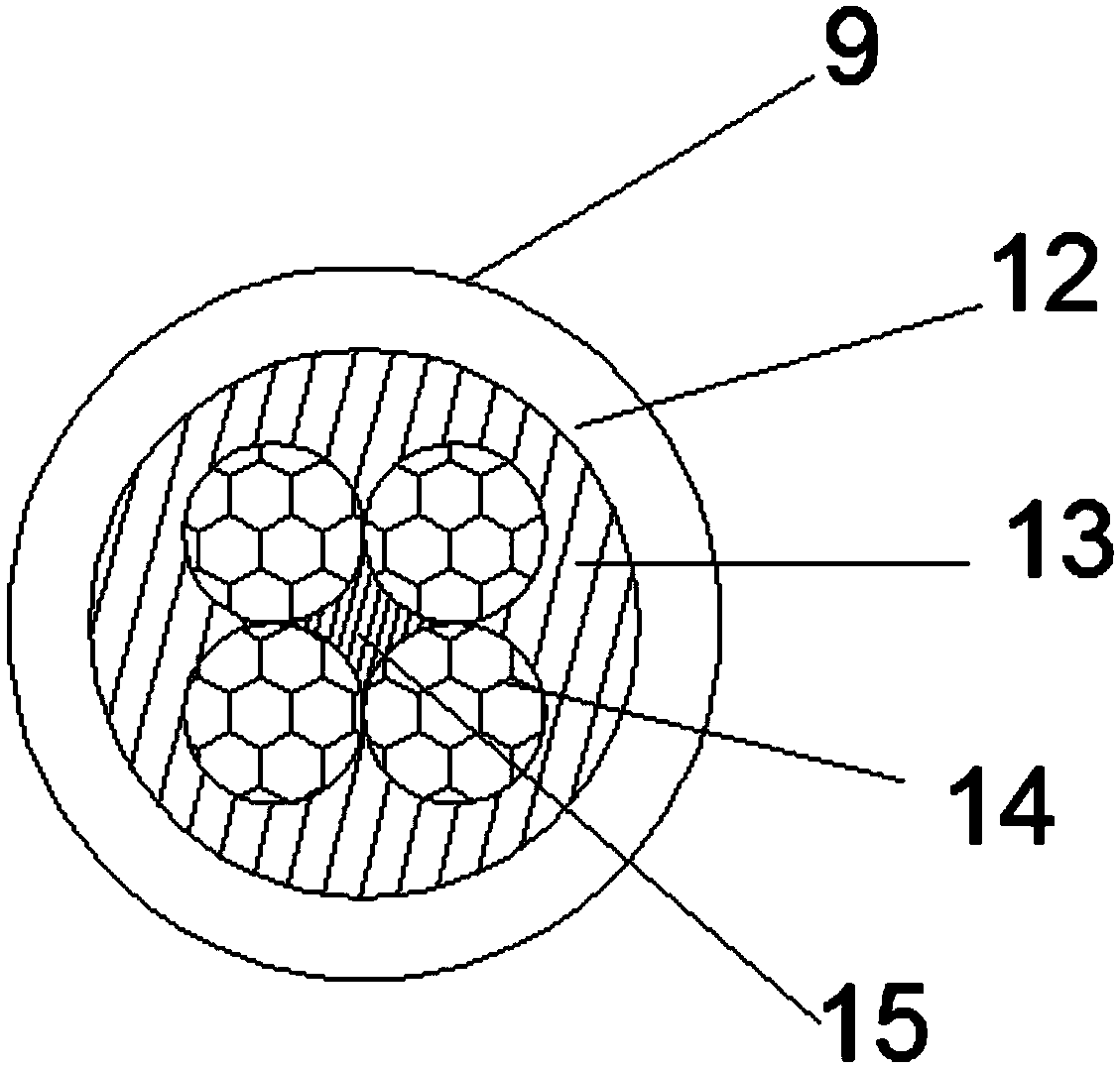

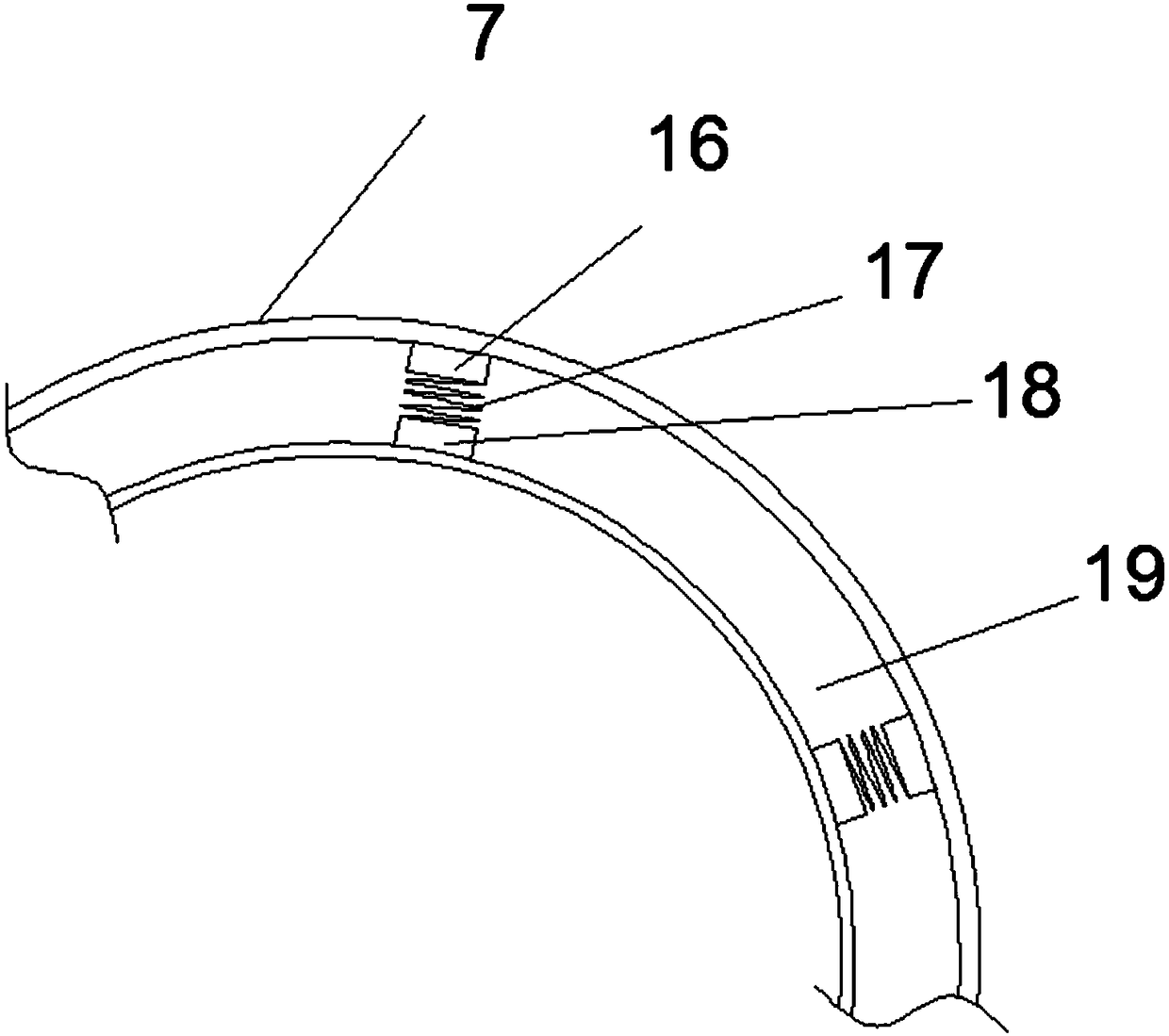

[0021] The inner wall of the buffer layer 7 is provided with a plurality of support blocks 8, and the center of the inner side of the buffer layer 7 is provided with a pull wire core 10, and a plurality of cable bodies 9 are arranged outside the pull wire core 10, and a filling layer 20 is arranged inside the buffer layer 7, and the pull wire The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com