2-functionality-degree polyether urethane acrylate and preparation method and application thereof

A technology of urethane acrylate and isocyanate ethyl acrylate, applied in the field of materials, can solve the problems of difficult control of the production process, many steps in the reaction process, cumbersome and other problems, and achieve the effects of easy control, reduction of reaction steps and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

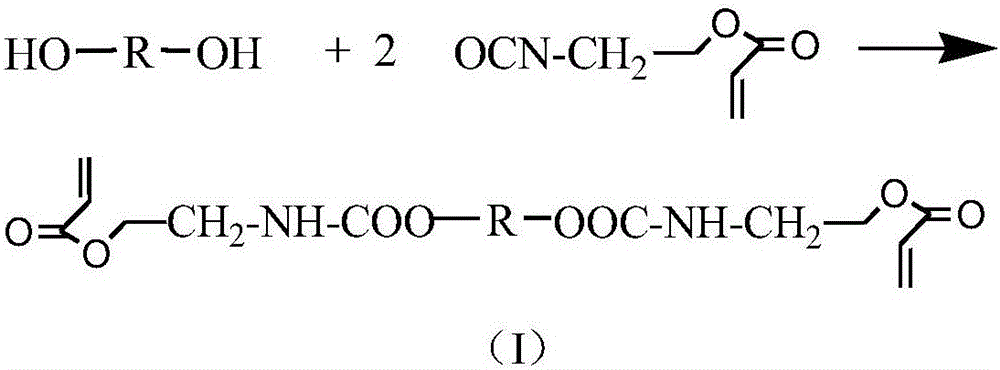

Method used

Image

Examples

Embodiment 1

[0031] In the 1000mL four-necked flask, drop into 600 grams of polyether glycol (Jiangsu Haian Petrochemical Plant, Polyethylene Glycol PEG600, molecular weight 600), 282 grams (2mol) of isocyanate ethyl acrylate, 0.1 gram of catalyzer dibutyltin dilaurate, The polymerization inhibitor p-hydroxyanisole is 0.9 g, and the temperature is slowly raised to 80°C-85°C for 0.5-4 hours, and the temperature is kept for 3-5 hours, and the material is discharged, and the bifunctional polyether polyurethane acrylate with the structure shown in the following formula is obtained.

[0032]

[0033] R is: -(CH 2 CH 2 O) n CH 2 CH 2 -;

[0034] n=(600-62) / 44=12.2273.

Embodiment 2

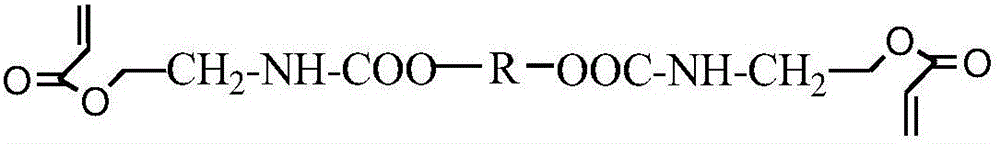

[0036] In a 1000mL four-necked flask, drop into 500 grams of polyether glycol (the third petrochemical plant of Tianjin Petrochemical Company, polypropylene glycol Tdiol-1000, molecular weight 1000), 141 grams (1mol) of isocyanate ethyl acrylate, catalyst dibutyltin dilaurate 0.1 g, 0.7 g of the polymerization inhibitor p-hydroxyanisole, slowly heating up to 80°C-85°C for 0.5-4 hours, heat preservation and reaction for 3-5 hours, and then the two-functionality polycaprolactone with the structure shown in the following formula is obtained Polyurethane acrylate.

[0037]

[0038] R is:

[0039] n=(1000-76) / 58=15.9310.

Embodiment 3

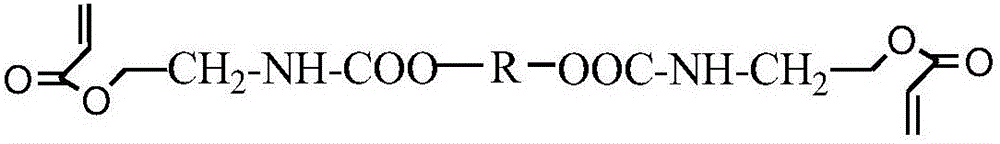

[0041] In a 1000mL four-necked flask, 500 grams of polyether diol (Chongqing Chiyuan Chemical Co., Ltd., polytetrahydrofuran ether glycol PTMEG2000, molecular weight 2000), 70.5 grams (0.5 mol) of isocyanate ethyl acrylate, and 0.1 dibutyltin dilaurate as a catalyst gram, 0.6 grams of polymerization inhibitor p-hydroxyanisole, slowly warming up to 80 ℃ to 85 ℃ for 3 to 5 hours and discharging in 0.5 to 4 hours to prepare the 2-functionality polycaprolactone polyurethane with the structure shown in the following formula Acrylate.

[0042]

[0043] R is: -(CH 2 CH 2 CH 2 CH 2 O) n CH 2 CH 2 CH 2 CH2 -;

[0044] n=(2000-90) / 72=26.5278.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com