Asphalt sizing material for waterproof coiled material, preparation method of asphalt sizing material, and waterproof coiled material

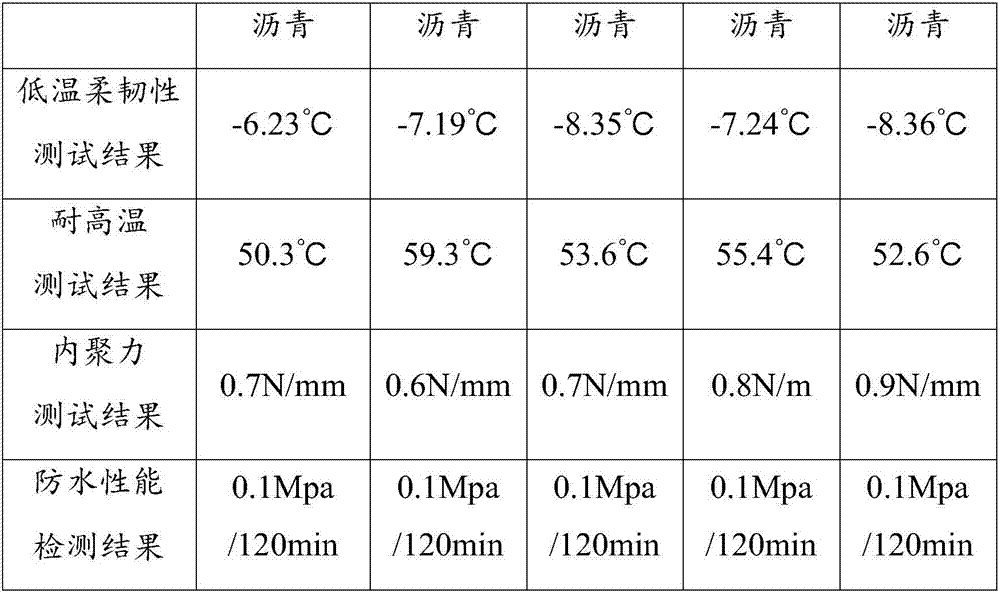

A waterproof membrane and asphalt glue technology, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of easy breakage, poor flexibility at low temperature, and inability to withstand high temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] According to one aspect of the present invention, a kind of preparation method of the bituminous compound that is used for waterproof membrane, described method comprises the following steps: first, mix asphalt, styrene-butadiene rubber, petroleum resin, polypropylene wax, erucamide and stabilizer After the agent is compounded and mixed, the temperature is raised to 200-250°C for reaction, and then the temperature is lowered to 130-170°C, and the softener is added and stirred to obtain a rubber compound.

[0048] The preparation method of the bituminous compound used for waterproof coils of the present invention comprises the steps of compounding asphalt, styrene-butadiene rubber, petroleum resin and a stabilizer, then raising the temperature for reaction, and then cooling down and adding a softener to stir to prepare the rubber compound. The method has the advantages of simple technological process, simple operation, low production cost, stable quality and the like.

...

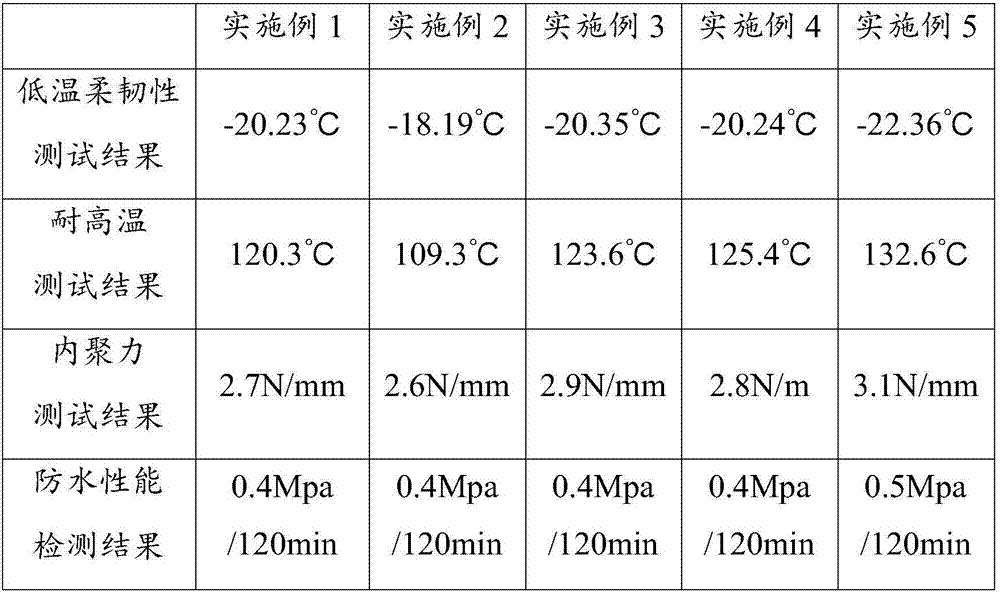

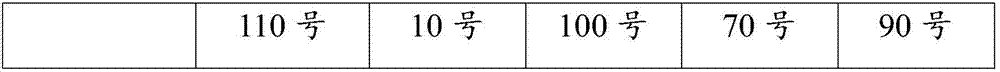

Embodiment 1

[0063] A kind of asphalt rubber material for waterproof coiled material, in parts by weight, said asphalt rubber material is mainly prepared from the following raw materials: 60 parts of No. 110 asphalt, 5 parts of No. 1006 styrene-butadiene rubber, and 5 parts of C5 petroleum resin , 15 parts of polypropylene wax, 15 parts of erucamide, 5 parts of rubber oil and 1 part of lead salt.

[0064] The preparation method of the above-mentioned asphalt compound is as follows: Weigh the raw materials according to the above-mentioned parts by weight, and then compound and mix No. 110 asphalt, No. 1006 styrene-butadiene rubber, C5 petroleum resin, polypropylene wax, erucamide and lead salt Afterwards, the temperature was raised to 200°C for 3 hours of reaction, and stirring was carried out during the reaction at a stirring speed of 100r / min; then, the temperature was lowered to 130°C, and then rubber oil was added and stirred for 20 minutes to obtain a rubber compound.

Embodiment 2

[0066] A kind of asphalt rubber material for waterproof coiled material, in parts by weight, said asphalt rubber material is mainly prepared from the following raw materials: 70 parts of No. 10 asphalt, 20 parts of No. 1019 styrene-butadiene rubber, and 15 parts of C9 petroleum resin , 5 parts of polypropylene wax, 5 parts of erucamide, 15 parts of rubber oil and 5 parts of metal soap.

[0067] The preparation method of the above-mentioned asphalt compound is as follows: Weigh the raw materials according to the above-mentioned parts by weight, and then compound and mix No. 10 asphalt, No. 1019 styrene-butadiene rubber, C9 petroleum resin, polypropylene wax, erucamide and metal soap Afterwards, the temperature was raised to 250°C for 10 hours of reaction, and stirring was carried out during the reaction at a stirring speed of 300r / min; then, the temperature was lowered to 170°C, and then rubber oil was added and stirred for 40 minutes to obtain a rubber compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com