Low-temperature rapidly cured acrylic ester modified epoxy resin joint sealant used in road and bridge

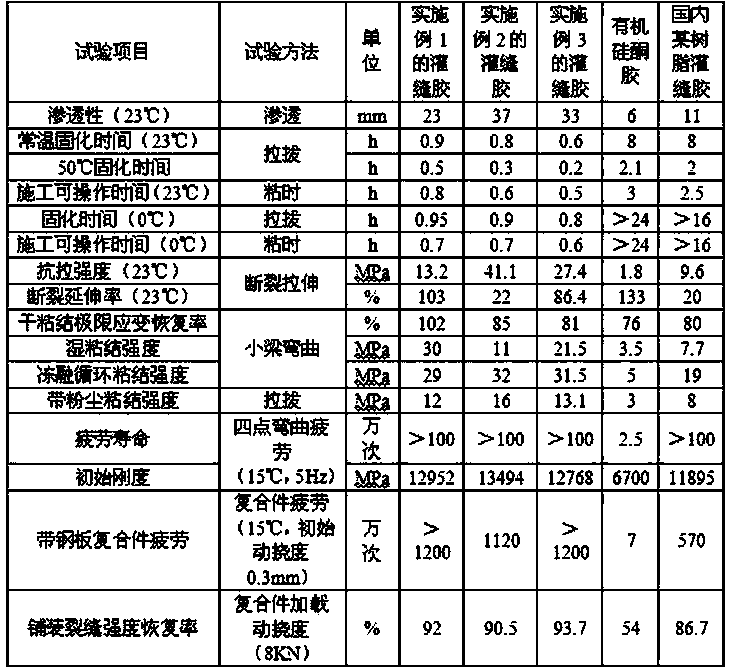

A fast-curing, acrylate technology, used in modified epoxy resin adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of prolonged curing time, affecting the normal traffic of bridges, and water resistance. , to achieve the effect of preventing secondary fatigue cracking, excellent low temperature permeability, and excellent adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Raw material preparation:

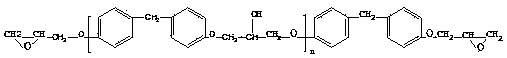

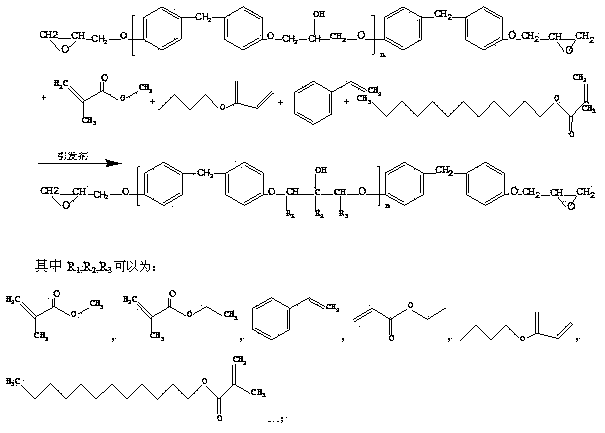

[0033] 1) Graft-polymerized epoxy resin and acrylic acid (ester) copolymer: Take 40 parts of bisphenol F diglycidyl ether (BPF), 5 parts of methyl methacrylate, 5 parts of ethyl methacrylate, methacrylic acid After 10 parts were mixed, 0.2% by mass of BPO promoter was added, and the reaction was carried out for 6.5-7h under a protective gas atmosphere and an oil bath temperature of 90°C, subject to the end of the reaction exotherm, to prepare a graft-polymerized ring Oxygen resin and acrylic copolymer, ready to use.

[0034] 2) Acrylic monomer: Take 15 parts of methyl methacrylate, 10 parts of ethyl methacrylate, 12 parts of styrene, 8 parts of lauryl methacrylate, 6 parts of acetoacetate ethyl methacrylate (AAEM), γ - 2 parts of methacryloxypropyltrimethoxysilane, 1 part of N-methylolacrylamide, 1 part of N-butylmethyl (meth)acrylamide, 1 part of 2-hydroxyethyl acrylate, acrylic acid 1 part of 2-hydroxypropyl methacrylate, 1 part of 2-hydr...

Embodiment 2

[0042] Raw material preparation:

[0043] 1) Graft-polymerized epoxy resin and acrylic acid (ester) copolymer: Take 30 parts of bisphenol F diglycidyl ether (BPF), 15 parts of methyl methacrylate, 11 parts of ethyl methacrylate, methacrylic acid After mixing the 6 parts, add 0.2% by mass of the BPO accelerator, and react for 6.5-7 hours under the protective gas atmosphere and the temperature of the oil bath at 90°C. Subject to the end of the reaction exotherm, the graft-polymerized ring Oxygen resin and acrylic copolymer, ready to use.

[0044] 2) Acrylic monomer: Take 5 parts of methyl methacrylate, 3 parts of ethyl methacrylate, 3 parts of styrene, 12 parts of lauryl methacrylate, 5 parts of acetoacetate ethyl methacrylate (AAEM), γ - 1 part of methacryloxypropyltrimethoxysilane, 1 part of N-methylolacrylamide, 1 part of diacetone acrylamide (DAAM), 1 part of 2-hydroxyethyl acrylate, 2- 1 part of hydroxypropyl ester, 1 part of 2-hydroxyethyl methacrylate, and 1 part of 2-h...

Embodiment 3

[0052] Raw material preparation:

[0053] 1) Graft-polymerized epoxy resin and acrylic acid (ester) copolymer: Take 45 parts of bisphenol F diglycidyl ether (BPF), 22 parts of methyl methacrylate, 10 parts of ethyl methacrylate, methacrylic acid After mixing 8 parts of styrene and 4 parts of styrene, 0.5% by mass of BPO promoter was added, and the reaction was carried out for 7.5 hours under a protective gas atmosphere and at a temperature of 90°C in an oil bath. Branch polymerized epoxy resin and acrylic copolymer, ready to use.

[0054] 2) Acrylic monomer: Take 5 parts of methyl methacrylate, 3 parts of ethyl methacrylate, 3 parts of styrene, 12 parts of lauryl methacrylate, 5 parts of acetoacetate ethyl methacrylate (AAEM), γ - 1 part of methacryloxypropyltrimethoxysilane, 1 part of N-methylolacrylamide, 1 part of diacetone acrylamide (DAAM), 1 part of 2-hydroxyethyl acrylate, 2- 1 part of hydroxypropyl ester, 1 part of 2-hydroxyethyl methacrylate, 1 part of 2-hydroxyprop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com