Anticorrosive tough coating material for outdoor communication tower, and preparation method thereof

A communication tower and toughness technology, applied in the field of anti-corrosion toughness coatings for outdoor communication towers and their preparation, can solve the problems of lack of hydrophobicity and toughness, and achieve the effects of good cross-linking effect, long service life and enhanced density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

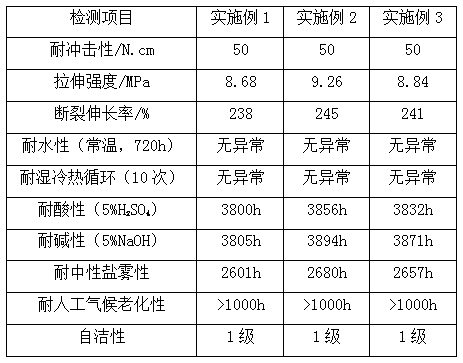

Examples

Embodiment 1

[0025] An anti-corrosion tough coating for an outdoor communication tower, which is made of the following raw materials in parts by weight:

[0026] 12 parts of polytrifluorochloroethylene resin, 35 parts of bisphenol A epoxy resin, 8 parts of polyphenylmethylsiloxane, 2 parts of α, ω-dihydroxypolydimethylsiloxane, amino-modified 2 parts of polysiloxane, 2 parts of hexamethyldisilazane, 2 parts of fumed nano-silica, 7 parts of short silicon carbide fiber, 12 parts of micaceous iron oxide powder, 2 parts of xylene, 10 parts of acetone aqueous solution, multi-component 1 part of amine mixed curing agent.

[0027] The polychlorotrifluoroethylene resin is a high temperature resistant and highly transparent polychlorotrifluoroethylene resin, which is prepared from chlorotrifluoroethylene in deionized water under the action of an azo initiator, Then use cobalt fluoride to end-cap the polychlorotrifluoroethylene in the system.

Embodiment 2

[0037] An anti-corrosion tough coating for an outdoor communication tower, which is made of the following raw materials in parts by weight:

[0038] 15 parts of polytrifluorochloroethylene resin, 40 parts of bisphenol A epoxy resin, 10 parts of polyphenylmethylsiloxane, 4 parts of α, ω-dihydroxypolydimethylsiloxane, amino-modified 4 parts of polysiloxane, 4 parts of hexamethyldisilazane, 4 parts of fumed nano-silica, 9 parts of short silicon carbide fiber, 14 parts of mica iron oxide powder, 5 parts of xylene, 15 parts of acetone aqueous solution, multi-component 2 parts of amine mixed curing agent.

[0039] The polychlorotrifluoroethylene resin is a high temperature resistant and highly transparent polychlorotrifluoroethylene resin, which is prepared from chlorotrifluoroethylene in deionized water under the action of an azo initiator, Then use cobalt fluoride to end-cap the polychlorotrifluoroethylene in the system.

[0040] The bisphenol A type epoxy resin is composed of E...

Embodiment 3

[0049] An anti-corrosion tough coating for an outdoor communication tower, which is made of the following raw materials in parts by weight:

[0050] 18 parts of polytrifluorochloroethylene resin, 45 parts of bisphenol A epoxy resin, 12 parts of polyphenylmethylsiloxane, 6 parts of α, ω-dihydroxypolydimethylsiloxane, amino-modified 6 parts of polysiloxane, 6 parts of hexamethyldisilazane, 6 parts of fumed nano-silica, 11 parts of short silicon carbide fiber, 16 parts of micaceous iron oxide powder, 8 parts of xylene, 20 parts of acetone aqueous solution, multi-component 3 parts of amine mixed curing agent.

[0051] The polychlorotrifluoroethylene resin is a high temperature resistant and highly transparent polychlorotrifluoroethylene resin, which is prepared from chlorotrifluoroethylene in deionized water under the action of an azo initiator, Then use cobalt fluoride to end-cap the polychlorotrifluoroethylene in the system.

[0052] The bisphenol A type epoxy resin is compose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| salt spray resistance time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com