Cylindrical lithium ion cell cap and assembly method

A technology of lithium-ion batteries and caps, which is applied to secondary batteries, battery pack components, circuits, etc., can solve problems such as cap failure and solder joint breakage, and achieve the effects of improving efficiency, reducing equipment investment, and improving process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Embodiment: a cap applied to a cylindrical lithium-ion battery 18650.

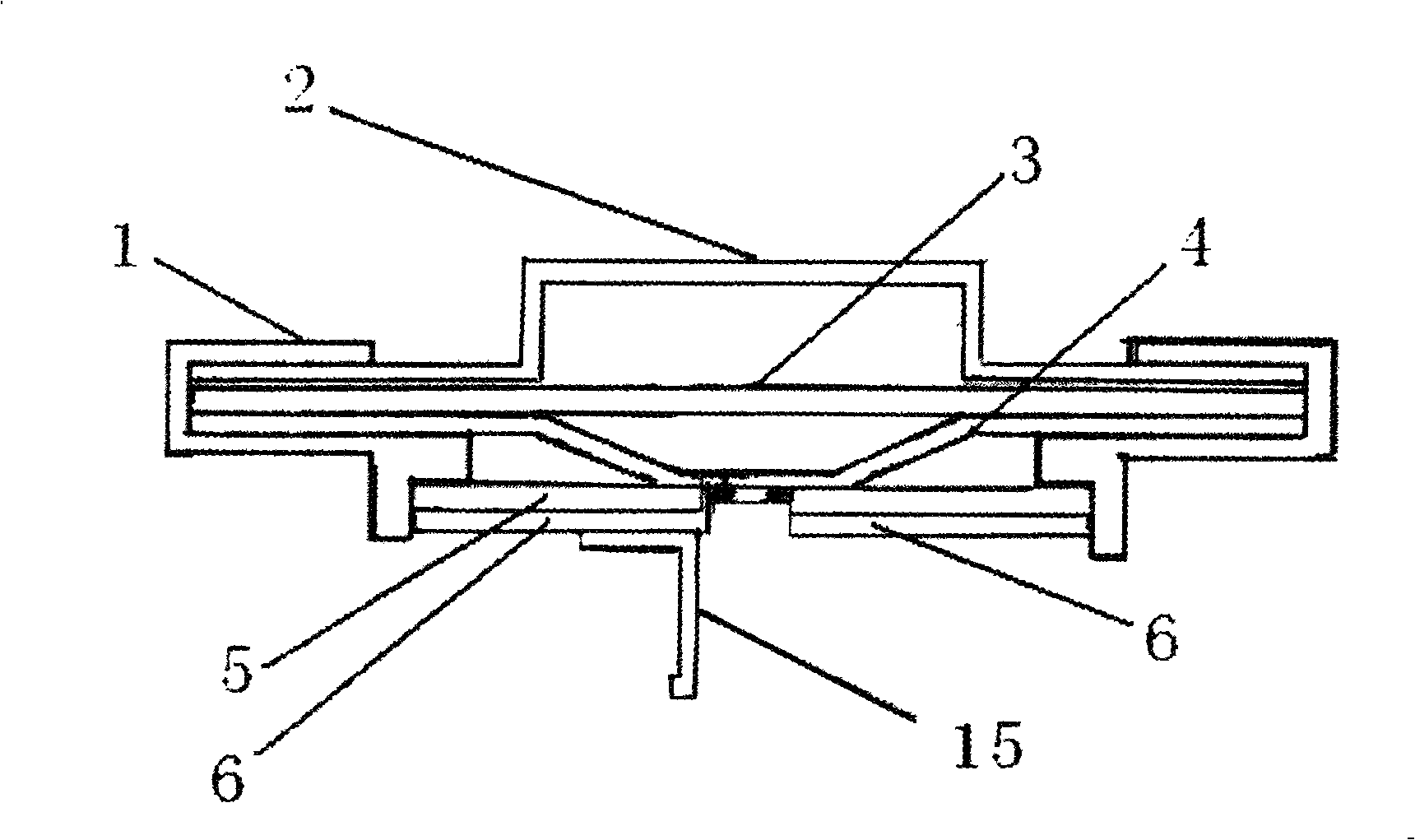

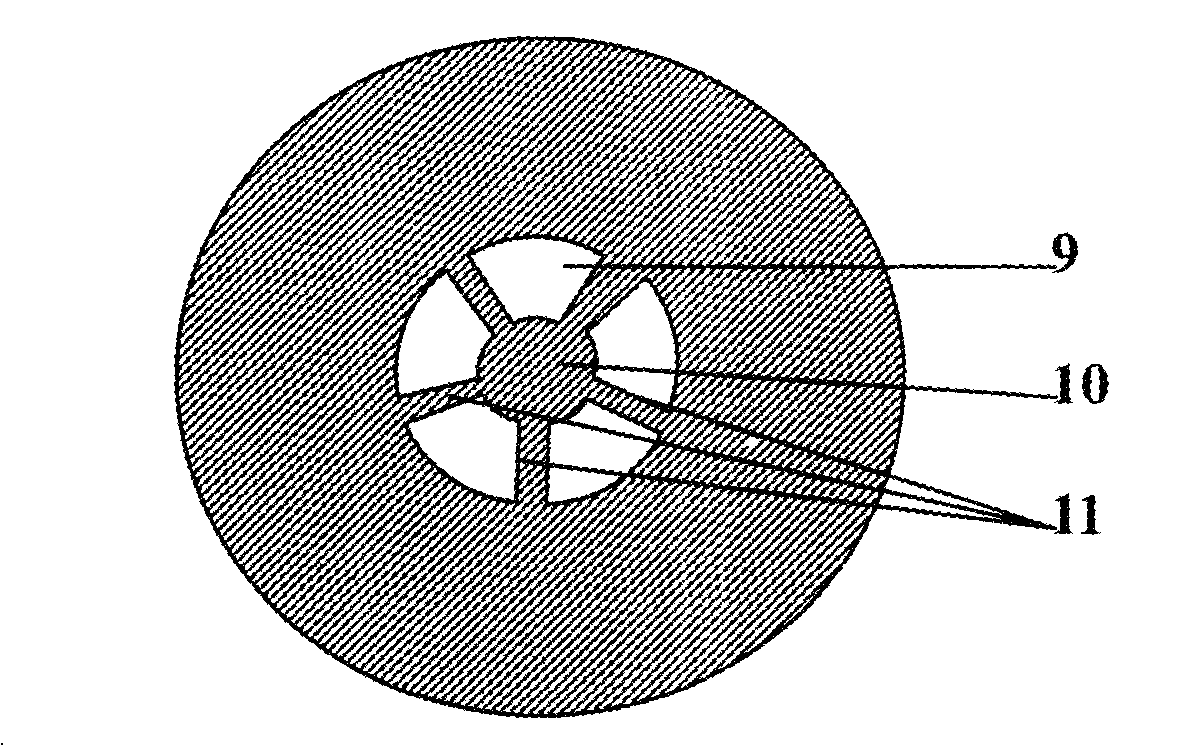

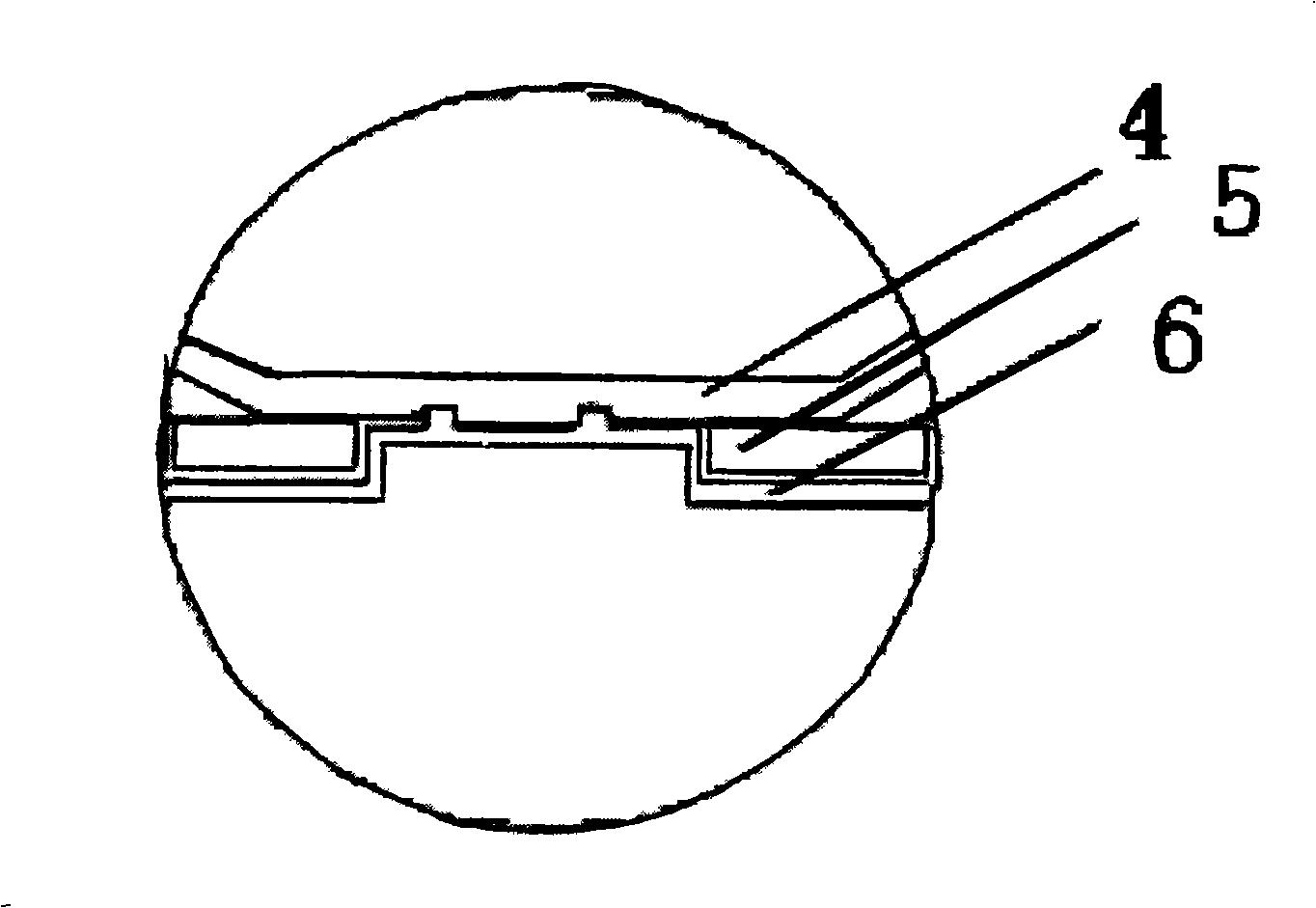

[0031] Sealing ring 1, positive external lead-out terminal (top cover) 2, PTC 3 and explosion-proof aluminum cake 4 adopt the general design, and their dimensions and materials do not change. The support plate 5 is punched from an aluminum-magnesium alloy plate with a thickness of 0.5mm, with an outer diameter of 13.8mm, a central through hole with a diameter of 3.5mm, and a ventilating round hole with a diameter of 1.8mm. The conductive shock absorbing plate 6 is punched from an aluminum-magnesium alloy plate with a thickness of 0.2mm, and is used after annealing at 400 degrees Celsius. The central pad 10 has a diameter of 3mm and a protrusion of 1.5mm. The outer diameter of the ventilating square hole 9 is 6.5mm and the width of the rib 11 0.5mm, the assembly method is the same as the general assembly method, that is, the explosion-proof aluminum cake 4 and the conductive shock absorbing plate 6 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com