Cylinder head for an air compressor

An air compressor and cylinder head technology, which is applied in the field of cylinder heads, can solve the problems of temperature, rise, etc. that are not raised, and achieve the effects of simplifying the production process, reducing the air volume flow, and reducing the mechanical driving power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

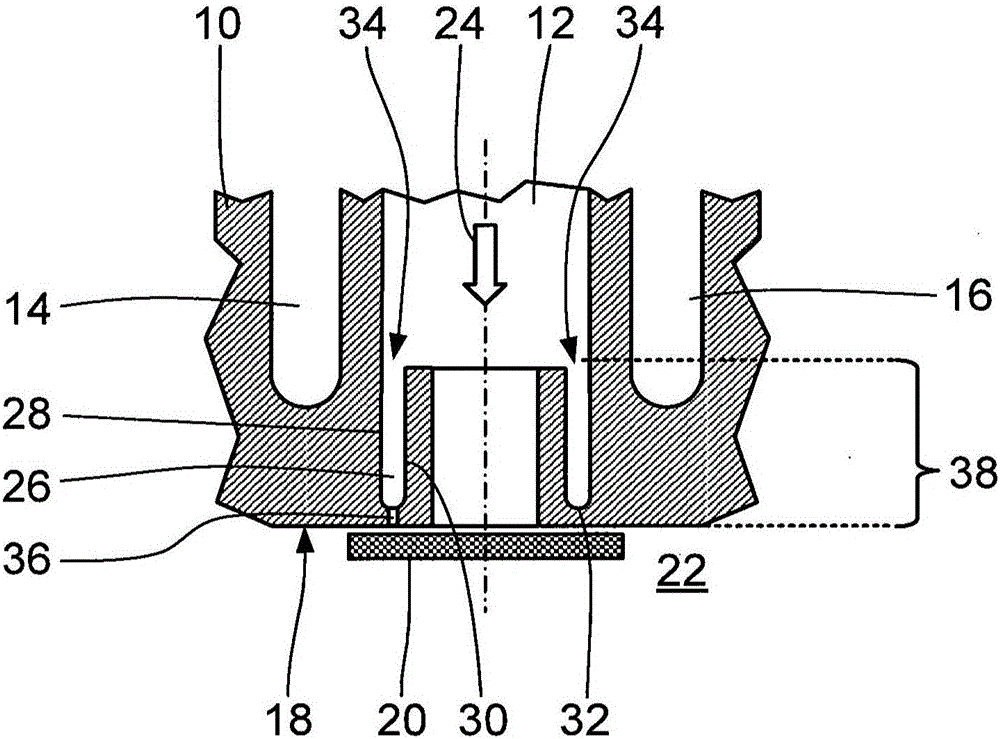

[0023] figure 1 Accordingly, a highly simplified longitudinal sectional view of a first embodiment of the cylinder head 10 according to the invention is shown. The cylinder head has, in particular, an approximately hollow-cylindrical intake channel 12 for drawing in air to be compressed or another gas or gas mixture from the surroundings, two cooling water channels 14, 16 and a pressure channel not shown in the figure, through which The pressure channel conducts compressed air out of the cylinder head 10 . The intake channel 12 can be closed pressure-tight with respect to the compression chamber 22 by means of the suction disc 20 which is movably arranged on the underside 18 of the cylinder head 10 . In this case, the air to be compressed is sucked in from the surroundings through the suction channel 12 in the flow direction 24 indicated by the arrow.

[0024] According to the invention, the suction channel 12 has an annular groove 26 close to the suction blade and surroundi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com