Novel air floatation thrust bearing and manufacturing method thereof

An air-float stop and thrust technology, which is applied to supports, manufacturing tools, metal processing mechanical parts, etc., can solve the problems of limiting fan performance and compressor blowing efficiency, no thrust plate for cooling and heat dissipation, and inability to further increase the speed. Achieve the effect of reducing the physical contact area, ensuring the thrust effect, and reducing the physical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

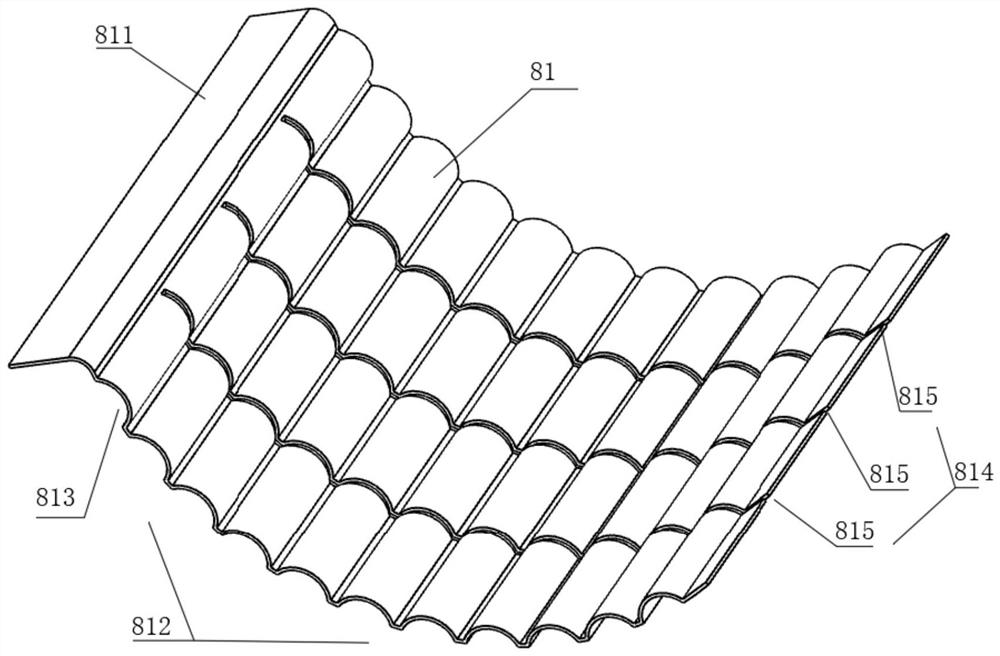

[0069] A method for preparing a novel thrust bearing, comprising the following steps:

[0070] Step 1, cutting the material, the process is: use an automatic cutting machine to cut the high temperature alloy steel strip material (GH4169) into the required size of the product (length × width × thickness: 55mm × 40mm × 0.15mm);

[0071] Step 2, solution treatment, the process is as follows: the material that has been cut in step 1 is sent into a vacuum furnace, heated to a certain temperature (1050° C.) with the furnace temperature, kept for a period of time (1h), and then vented and cooled ( Through metallographic observation, the material is cooled until the grain size of the grain structure becomes larger to 45 μm), so that the mechanical properties of the material meet the processing requirements;

[0072] The third step is to press the corrugation, and the process is as follows: the material that has completed the first heat treatment in the second step is pressed with a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com