Preparation method of EPE pearl wool for swarm heat preservation

The technology of pearl cotton and bee colony is applied in the field of preparation of EPE pearl cotton for bee colony heat preservation, which can solve the problems of affecting the use effect of beehives, poor heat preservation effect, easy breeding of bacteria, etc., so as to avoid breeding, reduce convection effect, improve The effect of antibacterial aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

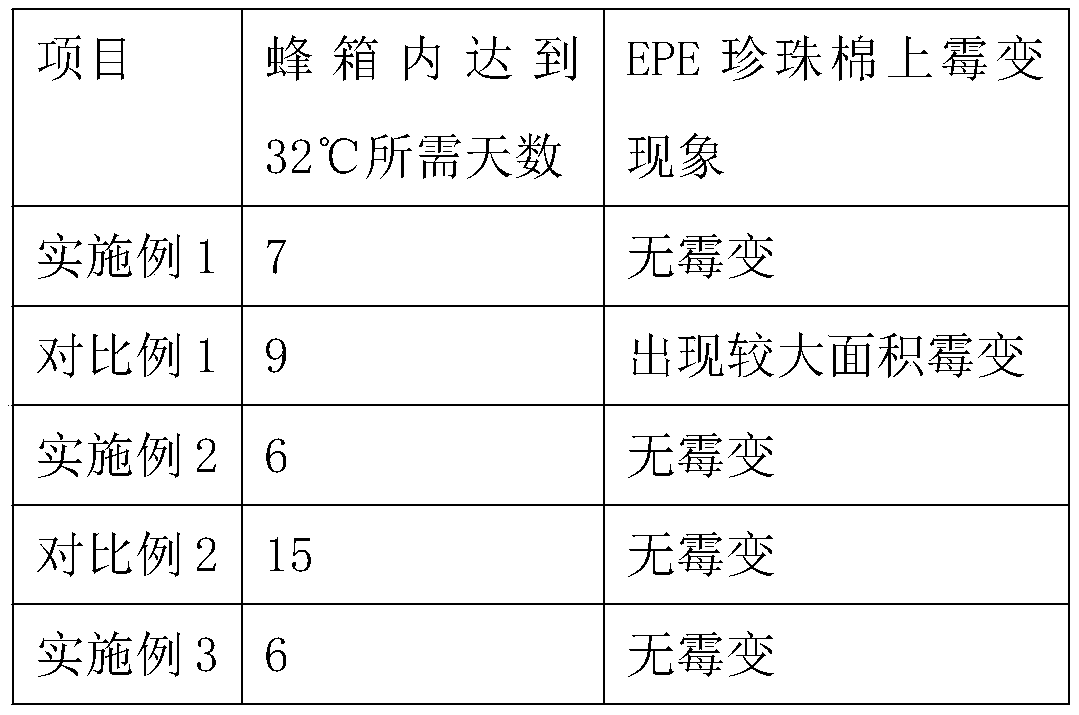

Examples

Embodiment 1

[0023] A preparation method of EPE pearl cotton for bee colony heat preservation, including the following operation steps:

[0024] (1) Add ε-polylysine with a molecular weight of 4500 and aminated multi-walled carbon nanotubes to deionized water at a mass ratio of 6:2, and mix and stir uniformly to prepare an antibacterial agent. ε-polylysine is added to 8 kg of deionized water, the outer diameter of the aminated multi-wall carbon nanotube is 8nm, the inner diameter is 2nm, and the length is 75um;

[0025] (2) Add per kilogram of shellac to 15kg of 95% ethanol aqueous solution until the shellac is completely dissolved, add the antibacterial agent to it, mix and stir uniformly, and then perform an ultrasonic bath for 20 minutes to prepare the modified Antibacterial agent, wherein the mass ratio of the added amount of shellac to the added amount of antibacterial agent is 1:5, the power density of the ultrasonic bath is 75W / L, and the ultrasonic treatment time is 10min;

[0026] (3) A...

Embodiment 2

[0029] A preparation method of EPE pearl cotton for bee colony heat preservation, including the following operation steps:

[0030] (1) Add ε-polylysine with a molecular weight of 4800 and aminated multi-walled carbon nanotubes to deionized water at a mass ratio of 7:2, and mix and stir uniformly to prepare an antibacterial agent. ε-polylysine is added to 9 kg of deionized water, the outer diameter of the aminated multi-walled carbon nanotube is 12nm, the inner diameter is 3nm, and the length is 75um;

[0031] (2) Add every kilogram of shellac to 18kg of 95% ethanol aqueous solution until the shellac is completely dissolved, add the antibacterial agent to it, mix and stir evenly, and then perform an ultrasonic bath for 25 minutes to obtain the modified Antibacterial agent, wherein the mass ratio of the added amount of shellac to the added amount of antibacterial agent is 1:7, the power density of the ultrasonic bath is 75W / L, and the ultrasonic treatment time is 10min;

[0032] (3) ...

Embodiment 3

[0035] A preparation method of EPE pearl cotton for bee colony heat preservation, including the following operation steps:

[0036] (1) Add ε-polylysine with a molecular weight of 5000 and aminated multi-walled carbon nanotubes to deionized water at a mass ratio of 9:2, and mix and stir uniformly to prepare an antibacterial agent. ε-polylysine is added to 10 kg of deionized water, the outer diameter of the aminated multi-walled carbon nanotube is 15nm, the inner diameter is 4nm, and the length is 75um;

[0037] (2) Add per kilogram of shellac to 20kg of 95% ethanol aqueous solution until the shellac is completely dissolved, add the antibacterial agent to it, mix and stir evenly, and then conduct an ultrasonic bath for 30 minutes to obtain the modified Antibacterial agent, wherein the mass ratio of the added amount of shellac to the added amount of antibacterial agent is 1:8, the power density of the ultrasonic bath is 75W / L, and the ultrasonic treatment time is 10min;

[0038] (3) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com