Heat insulation cold closet for medical supplies

A refrigerator and heat insulation technology, which is applied in the field of heat-insulated refrigerators for medical medicine, can solve the problems of large box size, heavy cold storage box, and impracticality, and achieve the effect of increasing the effective volume, reducing the thickness, and preventing heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

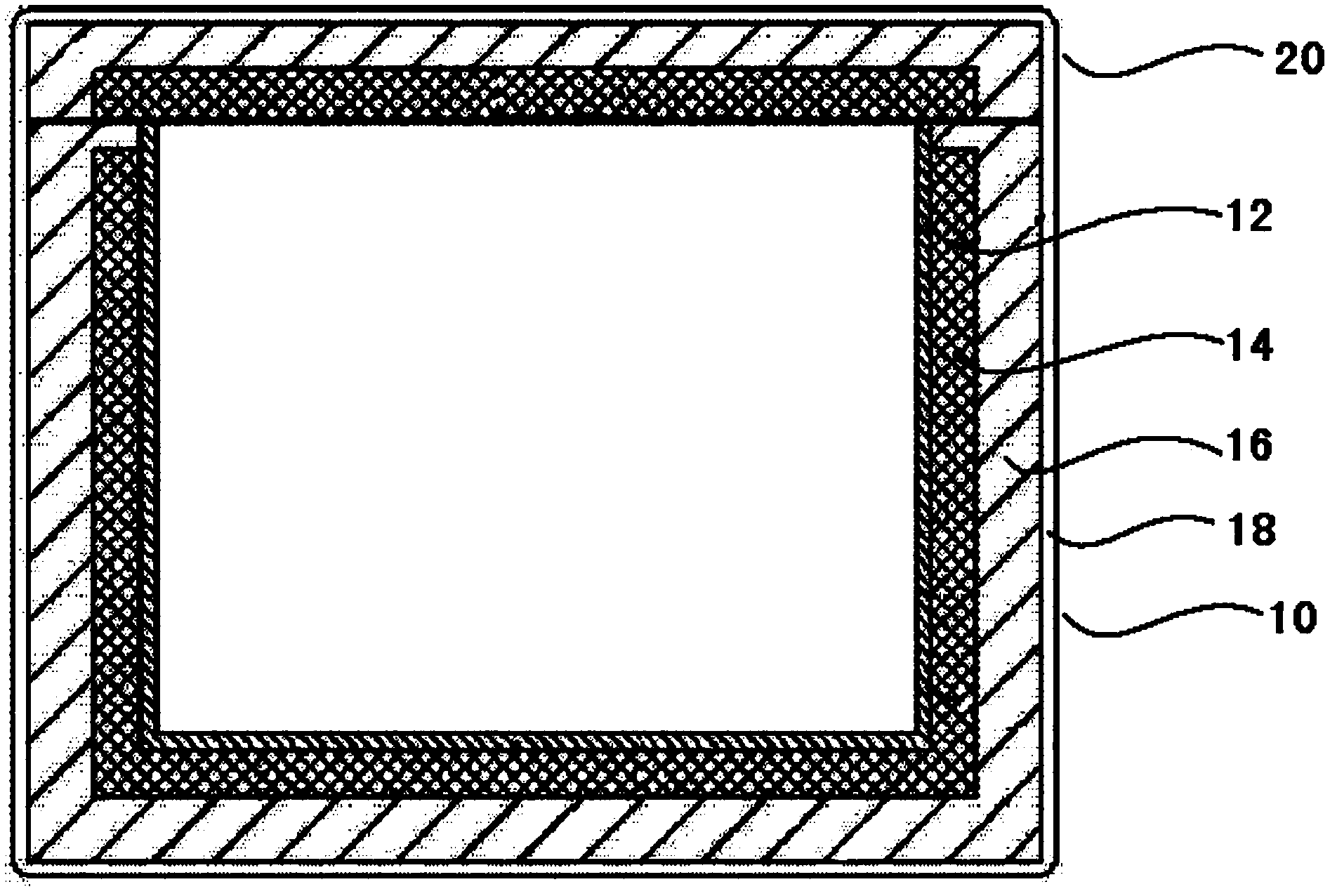

Embodiment 1

[0016] The hard polyurethane layer is composed of 23.5-25.0wt% MDI, 18.0-20.0wt% PEG1000, 5.0-5.5wt% PTMG1000, 2.0-2.2wt% 1,4-butanediol, 1.2-1.5wt% % of ethoxylated bisphenol F diacrylate, 1.5~1.8wt% of vinyltriethoxysilane, 0.20~0.25wt% of dibutyltin dilaurate, 5.0~5.5wt% of ethyl methyl carbonate and the balance The ethyl acetate is used to prepare the polyurethane prepolymer, which is then cast or coated. Specifically, at room temperature, stir the raw materials of the above ratio except dibutyltin dilaurate evenly, then adjust the temperature of the reaction solution to 83-85°C under a nitrogen atmosphere, and then add the ratio of dilaurate Acetate dibutyltin, react for 100-120 minutes, and after cooling, a polyurethane prepolymer can be obtained; then a hard polyurethane layer can be obtained by known casting or coating methods. The hard polyurethane layer has excellent mechanical properties. When the thickness of the hard polyurethane layer is 0.1mm, its tensile stren...

Embodiment 2

[0025] The vacuum insulation panel includes a core material and a sealing layer, the core material is a board formed of glass fiber and an air-absorbing composition, and the inside thereof maintains a vacuum; the sealing layer seals the core material, and the sealing layer The layer is formed by the first aluminum foil layer and the second aluminum foil layer laminated on the upper surface and the lower surface of the PET film layer; the thickness of the PET film layer is 100-120 μm, and the thickness of the first aluminum foil layer and the second aluminum foil layer is Both are 20-25 μm; and the first aluminum foil layer and the second aluminum foil layer are anodized to form an anodized aluminum film. The preparation method of described anodized aluminum film is as follows: first, aluminum foil layer is cleaned (with acid cleaning agent AcidClean UC, product of Atotech Co., Ltd. of Germany) for cleaning, and then immersing in 30°C, 5wt% sodium hydroxide aqueous solution fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com