Thermal radiation heating type electrostatic spinning machine

An electrospinning machine and thermal radiation technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of environmental interference of nanofibers, slow evaporation of spinning solution, etc., to avoid heat convection, Improved productivity and fiber surface morphology for easy observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

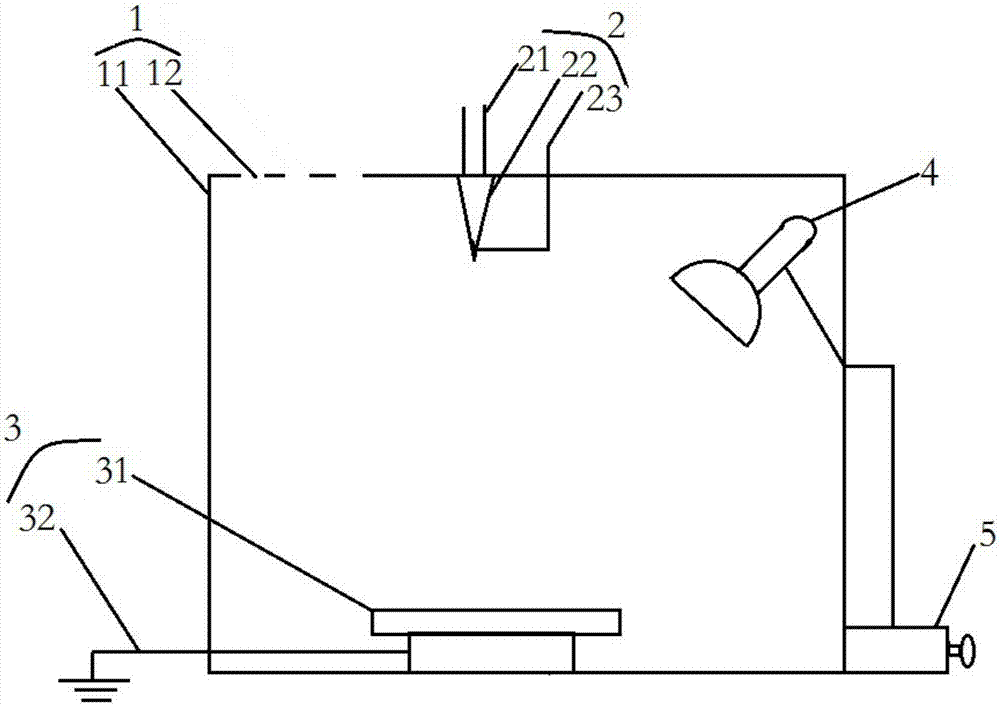

[0014] combine figure 1 , the present invention includes: a spinning solution injection device 2, a fiber receiving device 3, a thermal radiation heating device, a voltage regulation module 5, and a box body 1, the spinning solution injection device is arranged above the inside of the box body, and the nozzle is facing downward, The spinning solution injection device 2 includes a solution conduit 21, a nozzle 22, and a positive terminal 23 of a high-voltage power supply. The solution conduit 21 supplies liquid to the nozzle 22 of the spinning solution injection device and is arranged on the top of the box. The positive pole of the high-voltage power supply is connected through the positive pole of the high-voltage power supply. The column 23 is connected to the nozzle of the spinning solution injection device; the fiber receiving devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com