Carbon aerogel thermal insulation material and preparation method thereof

A technology for thermal insulation and carbon aerogel, which is applied in the field of thermal insulation materials, can solve the problems of high thermal conductivity and high price of silicon aerogel, and achieves small thermal conductivity, large application value and market potential, and high price. The effect of advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

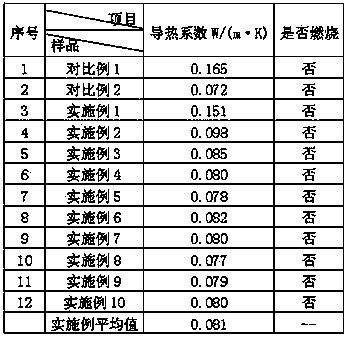

Examples

Embodiment 1

[0057] A carbon airgel thermal insulation material, the main components include: artificial inorganic fiber, expanded graphite, dispersant, adhesive, etc., wherein the mass ratio of each component is as follows:

[0058] Aluminum silicate fiber 100

[0059] Expanded graphite 0

[0060]Coconut Oil Diethanolamide 0.5

[0061] Vinyl acetate emulsion 0.5

[0062] Production is carried out according to a process comprising the following steps:

[0063] (1) In the high-speed stirring equipment, add water according to 5 times the total mass of the above components (man-made inorganic fibers, carbon materials, dispersants, adhesives), and start high-speed stirring;

[0064] (2) Add the coconut oil diethanolamide and vinyl acetate emulsion in the above ratio in sequence, and stir for 20 minutes;

[0065] (3) Add the above proportioned aluminum silicate fibers and expanded graphite in sequence, and stir for 20 minutes to prepare a slurry;

[0066] (4) Pour the slurry prepared in st...

Embodiment 2

[0071] A carbon airgel thermal insulation material, the main components include: artificial inorganic fiber, expanded graphite, dispersant, adhesive, etc., wherein the mass ratio of each component is as follows:

[0073] Expanded graphite 200

[0074] Coconut Oil Diethanolamide 0.5

[0075] Sodium succinate sulfonate 1.5

[0076] Styrene Acrylic Emulsion 2.0

[0077] Production is carried out according to a process comprising the following steps:

[0078] (1) In the high-speed stirring equipment, add water according to 100 times the total mass of the above components (man-made inorganic fibers, carbon materials, dispersants, adhesives), and start high-speed stirring;

[0079] (2) Add the coconut oil diethanolamide, sodium succinate sulfonate and styrene-acrylic emulsion in sequence, and stir for 40 minutes;

[0080] (3) Add the basalt fiber and expanded graphite in the ratio in sequence, and stir for 50 minutes to prepare a slurry;

[0081] (4) ...

Embodiment 3

[0088] A carbon airgel thermal insulation material, the main components include: artificial inorganic fibers, carbon materials, dispersants, adhesives, etc., wherein the mass ratio of each component is as follows:

[0090] Artificial mullite fiber 50

[0091] Expanded graphite 10

[0092] Activated carbon 10

[0093] Sodium succinate sulfonate 0.2

[0095] Styrene-acrylic emulsion 0.5

[0096] Vinyl acetate emulsion 0.5

[0097] Production is carried out according to a process comprising the following steps:

[0098] (1) In the high-speed stirring equipment, add water according to 50 times the total mass of the above components (man-made inorganic fibers, carbon materials, dispersants, adhesives), and start high-speed stirring;

[0099] (2) Add sodium succinate sulfonate, cellulose ether, vinyl acetate emulsion and styrene-acrylic emulsion in sequence, and stir for 30 minutes;

[0100] (3) Add the basalt fiber, arti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com