Flexible heat preservation assembly

A flexible and component technology, which is applied in the thermal insulation structure, flexible thermal insulation components, and the thermal insulation field of special-shaped components, can solve the problems of heat loss, increase the air supply volume, and poor installation accuracy, so as to block heat conduction and convection and ensure the sealing effect , Improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

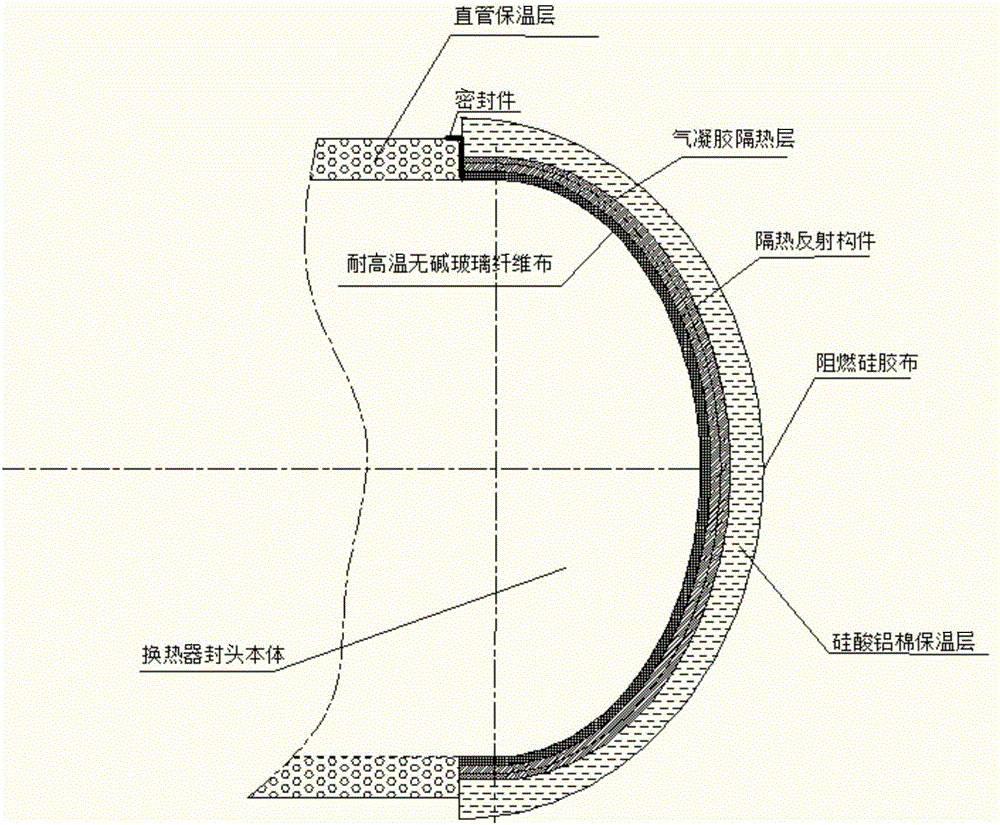

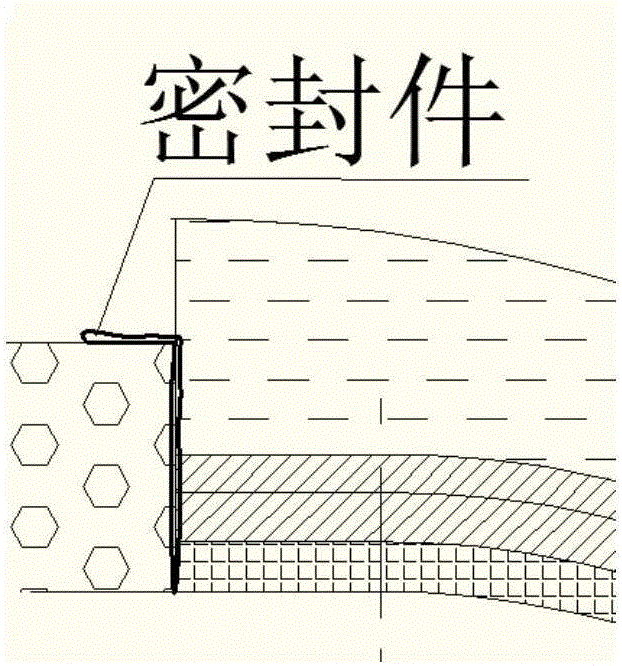

[0054] Figure 4a , 4b and Figure 5 An example of the application of the flexible thermal insulation component of the present invention to the head of a heat exchanger is given. Although the figure only shows an example of one layer of heat-insulating reflective member and two layers of heat-insulating layer, those skilled in the art know that the number of layers and positions of the heat-insulating reflective member and heat-insulating layer can be adjusted. The structure of the flexible thermal insulation component used for the heat exchange head is as follows from the inside to the outside: high temperature resistant alkali-free glass fiber cloth, heat insulation reflective member, airgel heat insulation layer, aluminum silicate cotton insulation layer, flame retardant silicone cloth ;Use flexible seals at the assembly's joints with straight pipe insulation or other structural joints.

[0055] Figure 5 yes Figure 4a Enlarged view of the middle seal. Since the head...

Embodiment 2

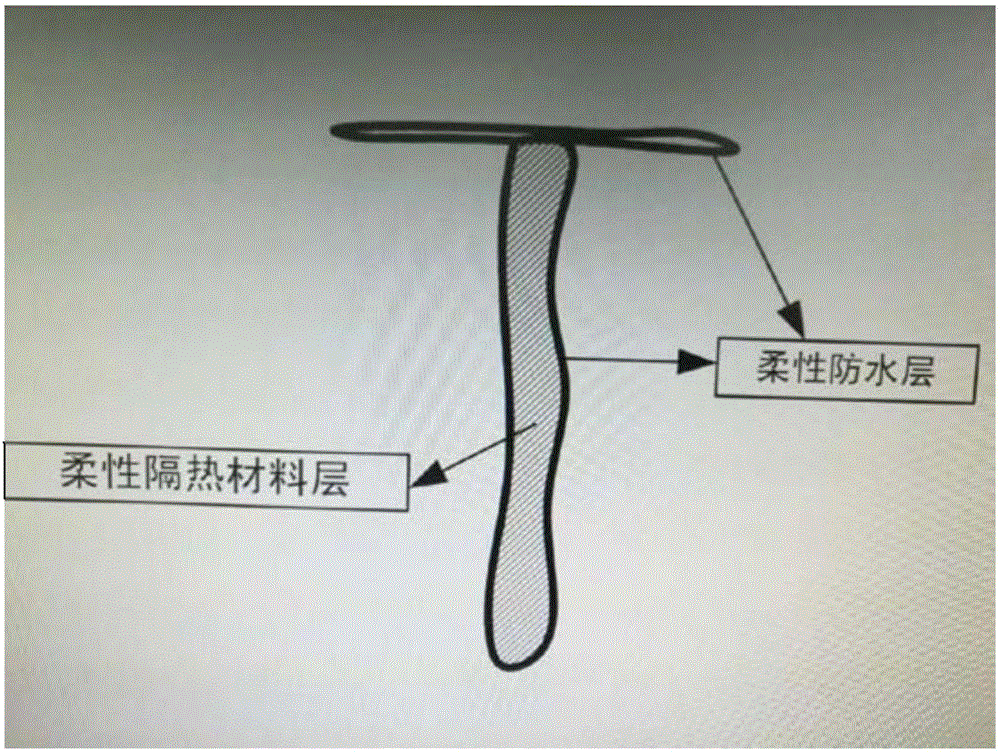

[0058] Figure 6 A schematic diagram of the application of the flexible thermal insulation component of the present invention to a flange is given. Although the figure only shows an example of one layer of heat-insulating reflective member and two layers of heat-insulating layer, those skilled in the art know that the number of layers and positions of the heat-insulating reflective member and heat-insulating layer can be adjusted. The structure of the flexible thermal insulation component used for the flange is from the inside to the outside: high temperature resistant alkali-free glass fiber cloth, heat insulation reflective member, airgel heat insulation layer, aluminum silicate wool heat insulation layer, flame retardant silicone cloth; Flexible seals are used at the seams.

[0059] In order to facilitate installation, the flexible thermal insulation component can be divided into two parts, prefabricated in the factory or on site, and then directly sleeved on the flange, t...

Embodiment 3

[0061] Figure 7 A schematic diagram of the application of the flexible thermal insulation component of the present invention to a valve is given. Although the figure only shows an example of one layer of heat-insulating reflective member and two layers of heat-insulating layer, those skilled in the art know that the number of layers and positions of the heat-insulating reflective member and heat-insulating layer can be adjusted. The structure of the flexible thermal insulation component used for valves is as follows from inside to outside: high temperature resistant alkali-free glass fiber cloth, heat insulation reflective member, airgel heat insulation layer, aluminum silicate cotton heat insulation layer, flame retardant silicone cloth; Use flexible seals at seams.

[0062] In order to facilitate installation, the flexible thermal insulation component can be divided into two parts, prefabricated in the factory or on site, and a straight pipe and a hole through which the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com