Vertical-type low-temperature heat-insulation gas cylinder

A low-temperature heat insulation and gas cylinder technology, which is applied to fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., to achieve the effects of gas saving, good heat insulation effect, and continuous and stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

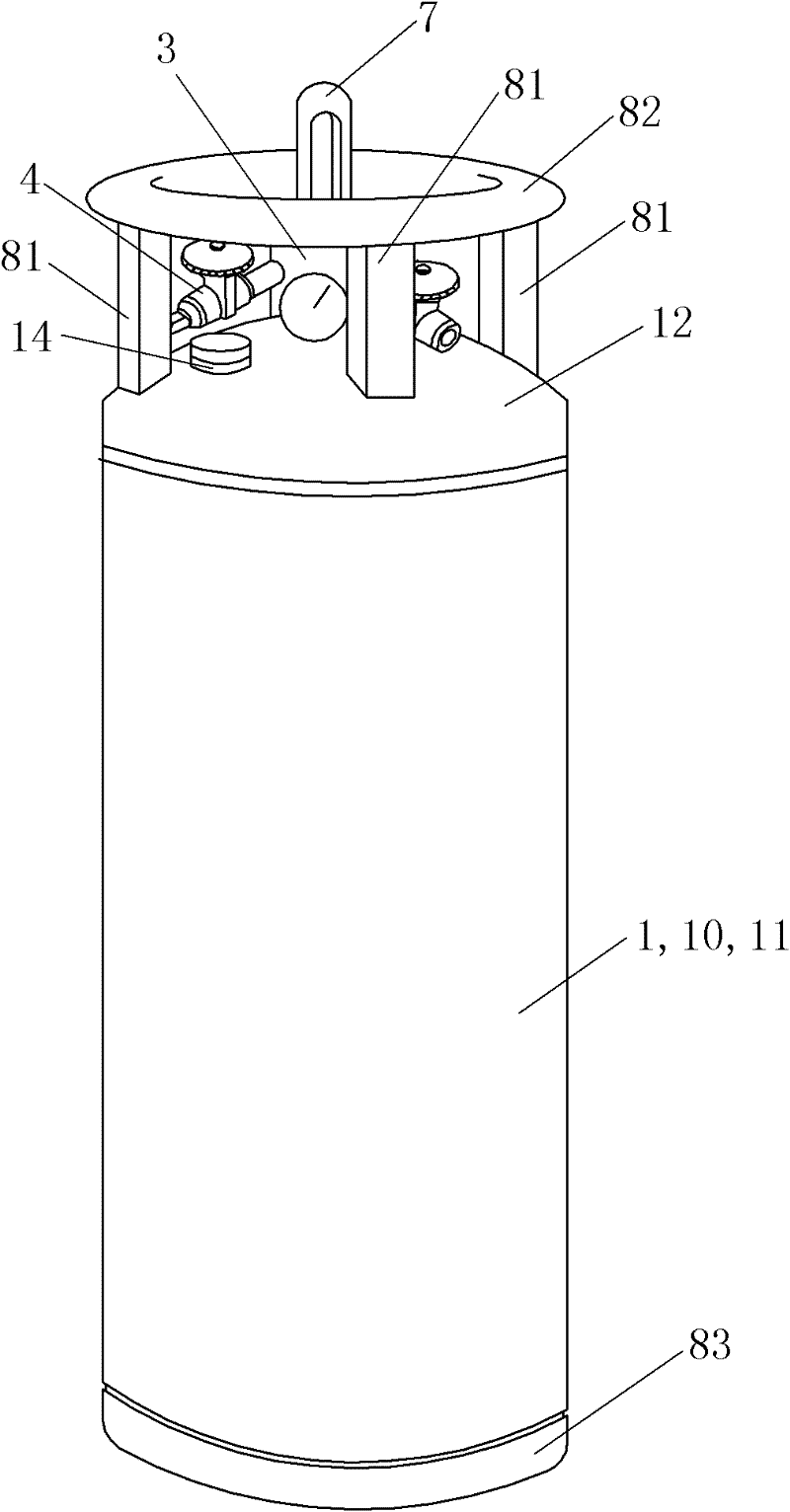

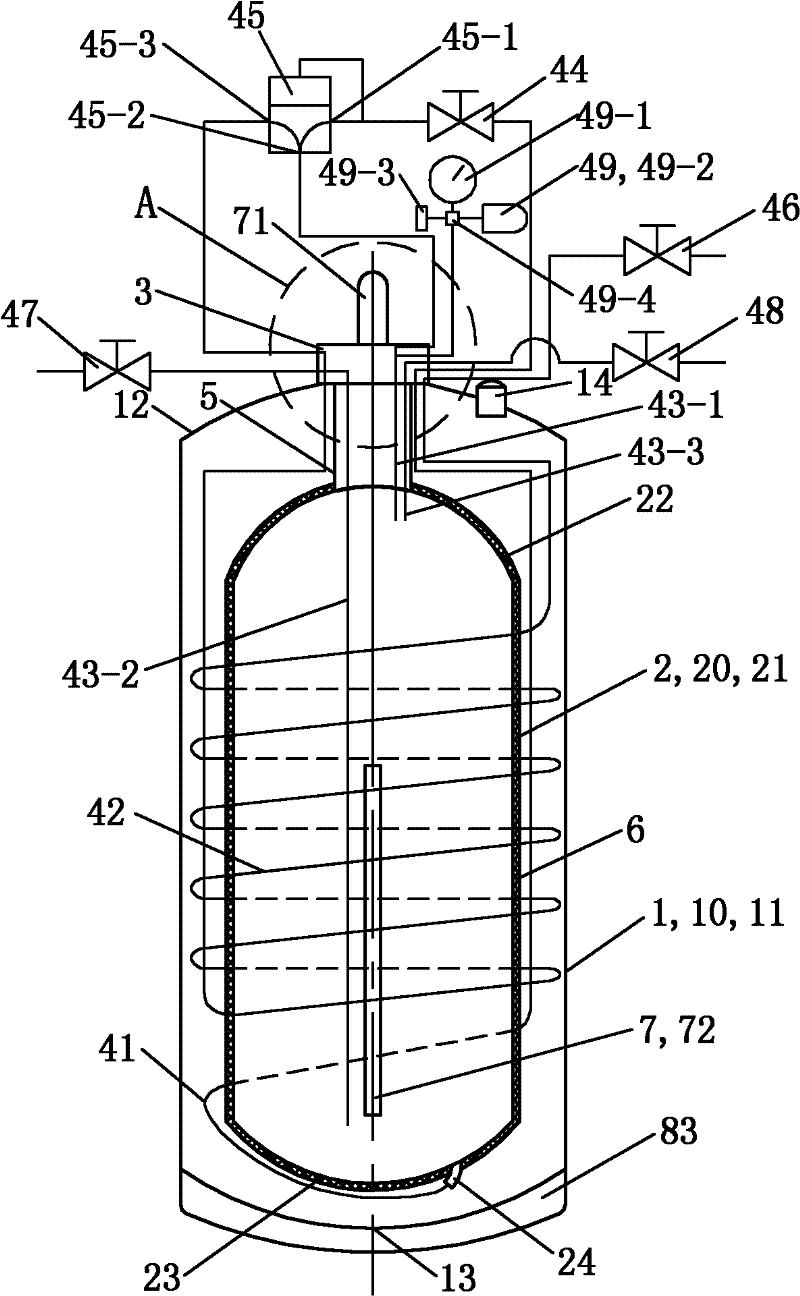

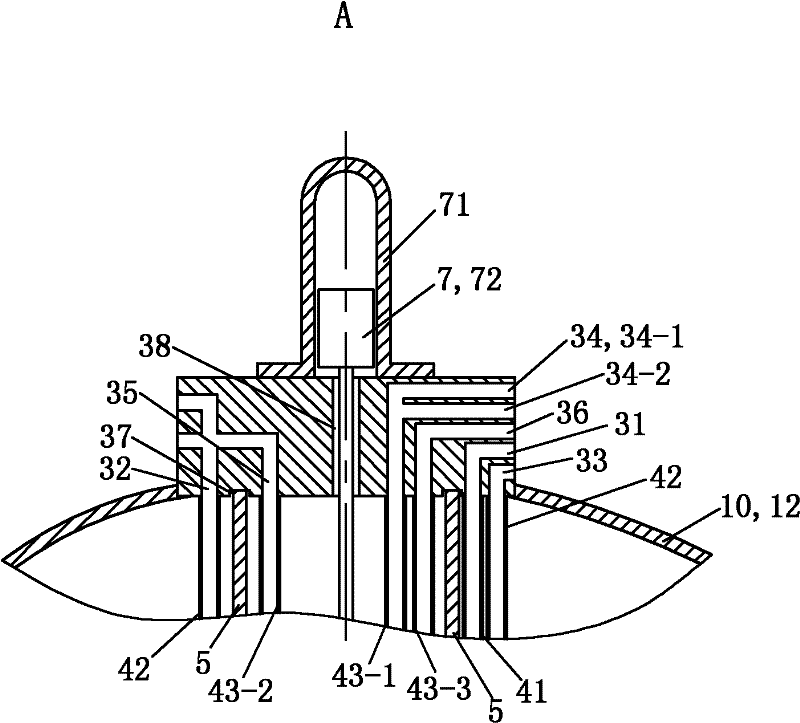

[0040] See figure 1 and figure 2 , the vertical cryogenic insulating gas cylinder of this embodiment includes a shell 1, an inner tank 2, a distributor 3, a pipeline control system 4, a neck tube 5, an insulating layer 6, a liquid level assembly 7, a protective ring pillar 81, and a protective ring 82 and base 83.

[0041] See figure 2 , the housing 1 includes a casing 10 and a vacuum interface 14 . The shell 10 includes a shell cylinder 11 , an upper shell head 12 and a lower shell head 13 .

[0042] The casing body 11 is in the shape of a cylinder, and is formed by bending a stainless steel plate and welding it through a longitudinal weld.

[0043] The upper shell head 12 is an arc-shaped curved plate with a downward opening and a central hole and a mounting hole. The central hole of the upper shell head 12 is also the central hole of the housing 10 . The vacuum interface piece 14 is airtightly and fixedly connected to the position of the installation hole of the arc-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com