Heat and sound insulation material and preparation method thereof

A sound insulation material and heat insulation technology, which is applied in the field of heat insulation and sound insulation materials and its preparation, can solve the problems of poor heat insulation effect, low NRC, harmful to human body, etc., and achieve good heat insulation, high economic benefits, and the effect of blocking heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

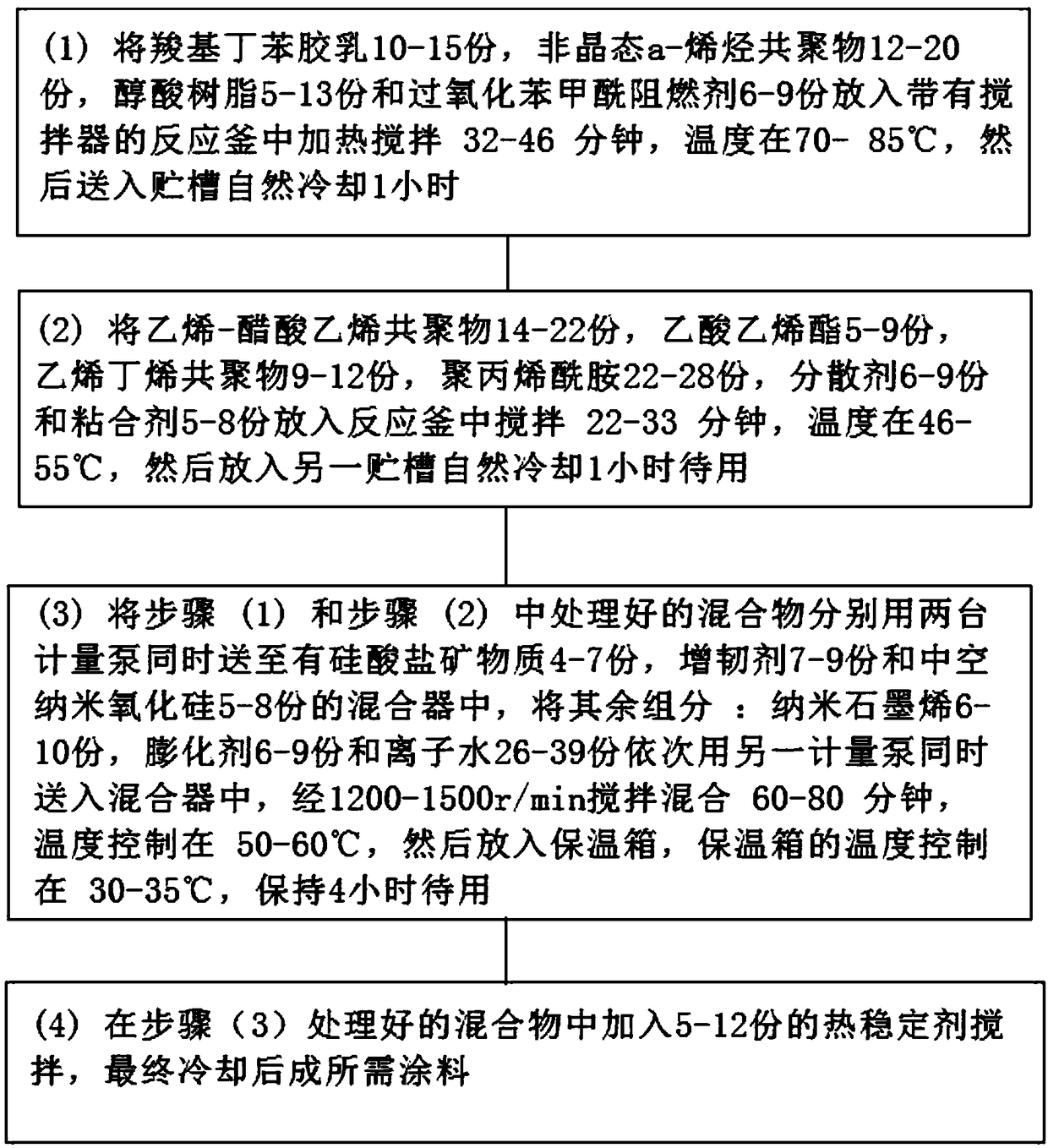

Method used

Image

Examples

Embodiment Construction

[0020] The invention discloses a heat-insulating and sound-insulating material, which is prepared from the following raw materials in parts by weight: 10-15 parts of carboxylated styrene-butadiene latex, 12-20 parts of amorphous a-olefin copolymer, 5-13 parts of alkyd resin, and 6-9 parts of benzoyl oxide flame retardant, 14-22 parts of ethylene-vinyl acetate copolymer, 5-9 parts of vinyl acetate, 9-12 parts of ethylene butene copolymer, 22-28 parts of polyacrylamide, dispersed 6-9 parts of agent, 5-8 parts of adhesive, 4-7 parts of silicate minerals, 7-9 parts of toughening agent, 5-8 parts of hollow nano-silicon oxide, 6-10 parts of nano-graphene, expanded 6-9 parts of agent, 5-12 parts of thermal stabilizer, 26-39 parts of ionized water.

[0021] Preferably, 10 parts of carboxylated styrene-butadiene latex, 12 parts of amorphous α-olefin copolymer, 5 parts of alkyd resin, 6 parts of benzoyl peroxide flame retardant, 14 parts of ethylene-vinyl acetate copolymer, 5 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com