Device and method for measuring superhigh temperature flexure elasticity modulus and fracture strain of material

A technology of flexural elastic modulus and fracture strain, which is applied in the direction of measuring device, using stable bending force to test material strength, analyzing materials, etc., can solve the requirements of exceeding the maximum service temperature, inapplicable bending test of brittle materials, and deformation measurement accuracy advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

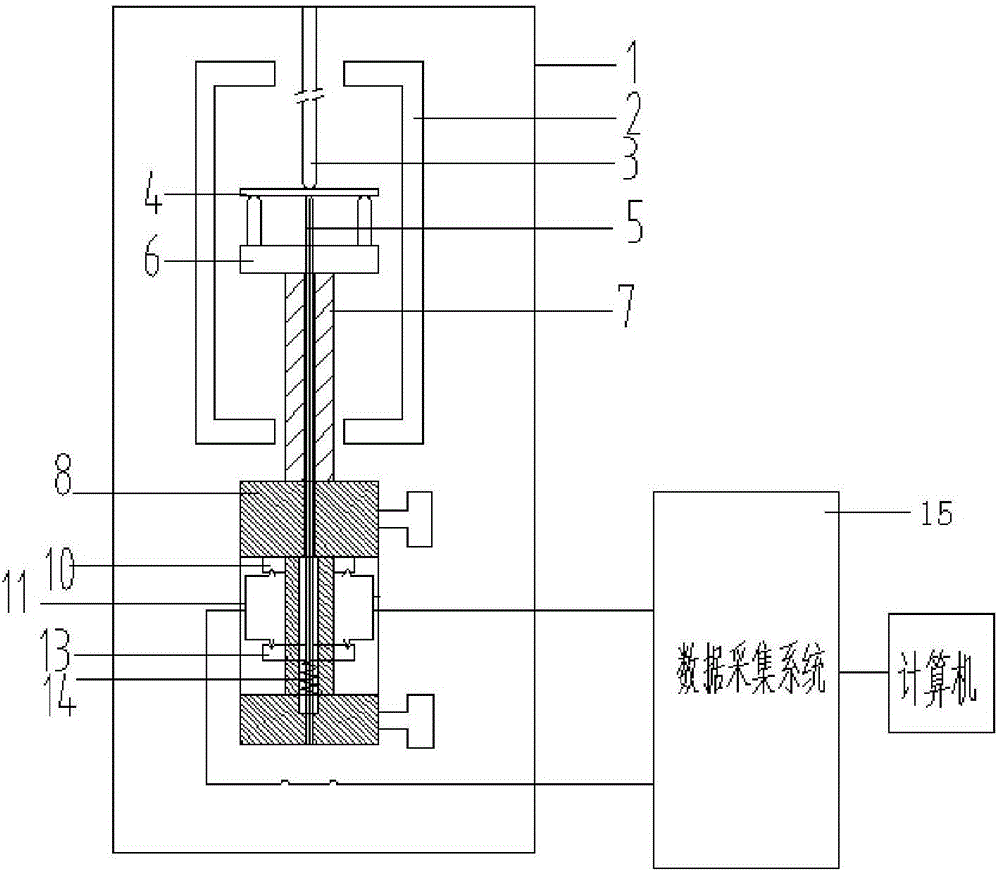

[0033] Devices for measuring ultra-high temperature flexural modulus and fracture strain of materials, such as figure 1 As shown, including load transfer structure, deformation transfer structure and deformation sensor 11,

[0034] The load transfer structure includes an upper pressing head 3, a lower pressing head 6, a lower pressing rod 7 at the hot end and a water-cooling protective sleeve 8. A through hole is provided in the center of the lower pressing head 6, and a bending sample 4 is placed on the lower pressing head 6. The indenter 3 is located above the center of the bending sample 4. The water-cooled protective cover 8 is a hollow water-cooled I-shaped structure, including upper and lower beams and middle columns, which are used to block the heat conducted by the lower pressing rod 7 at the hot end. The water-cooled protective cover 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| fracture strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com