Tooth element for a removing roller

A technology of toothed components and components, applied in the direction of unpacking with toothed tools, etc., can solve the problems of lack of stability, reducing the cleaning effect of toothed components, and blunt tooth tips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

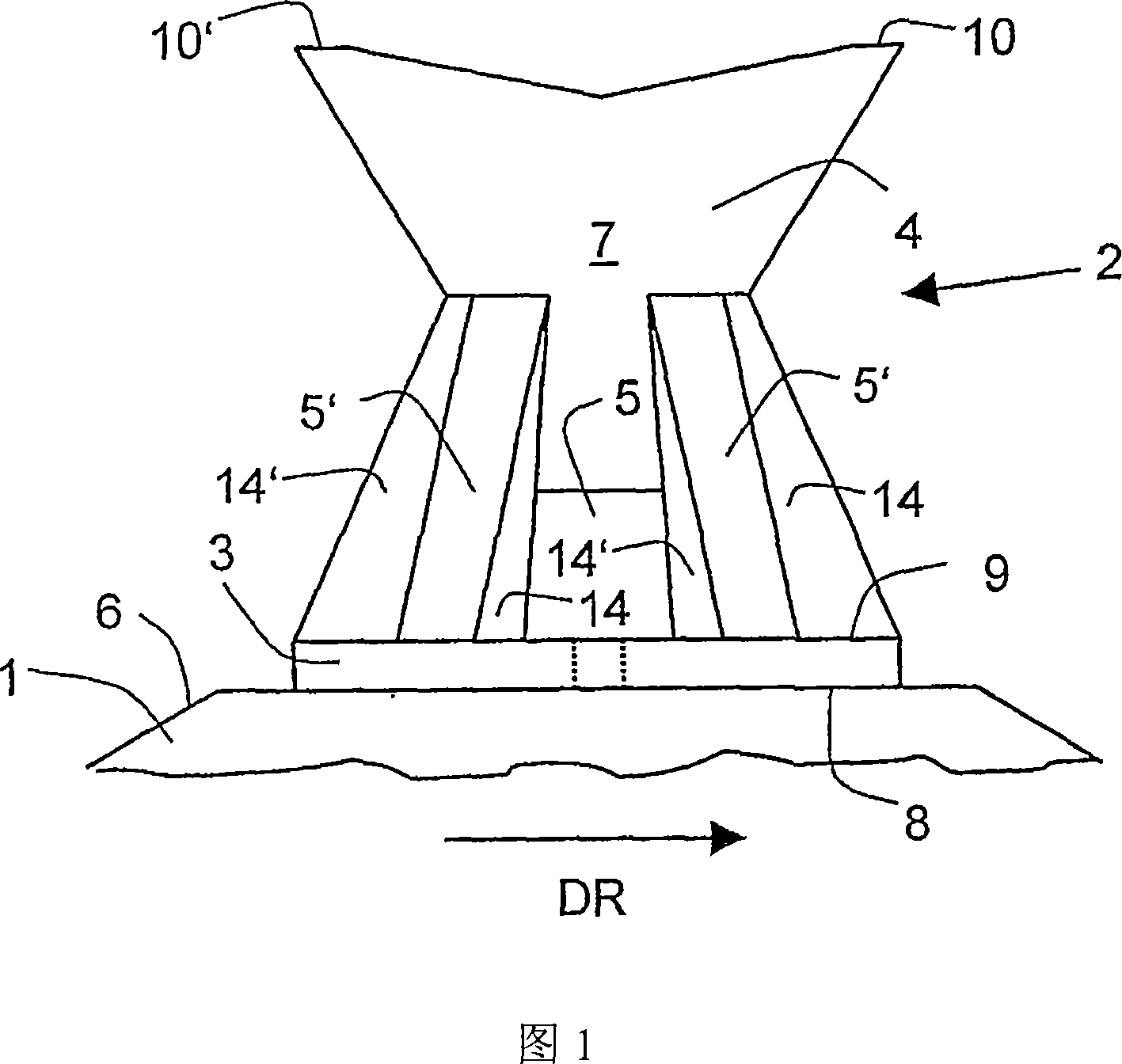

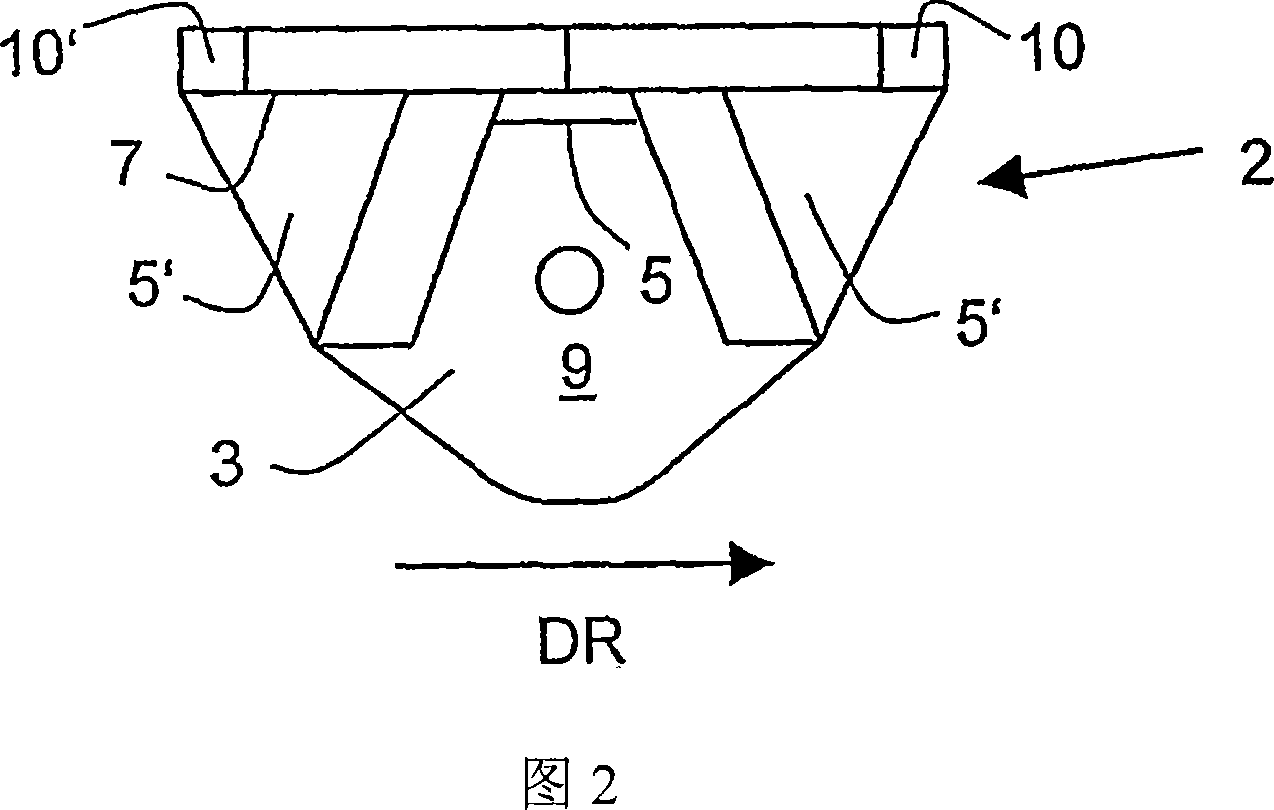

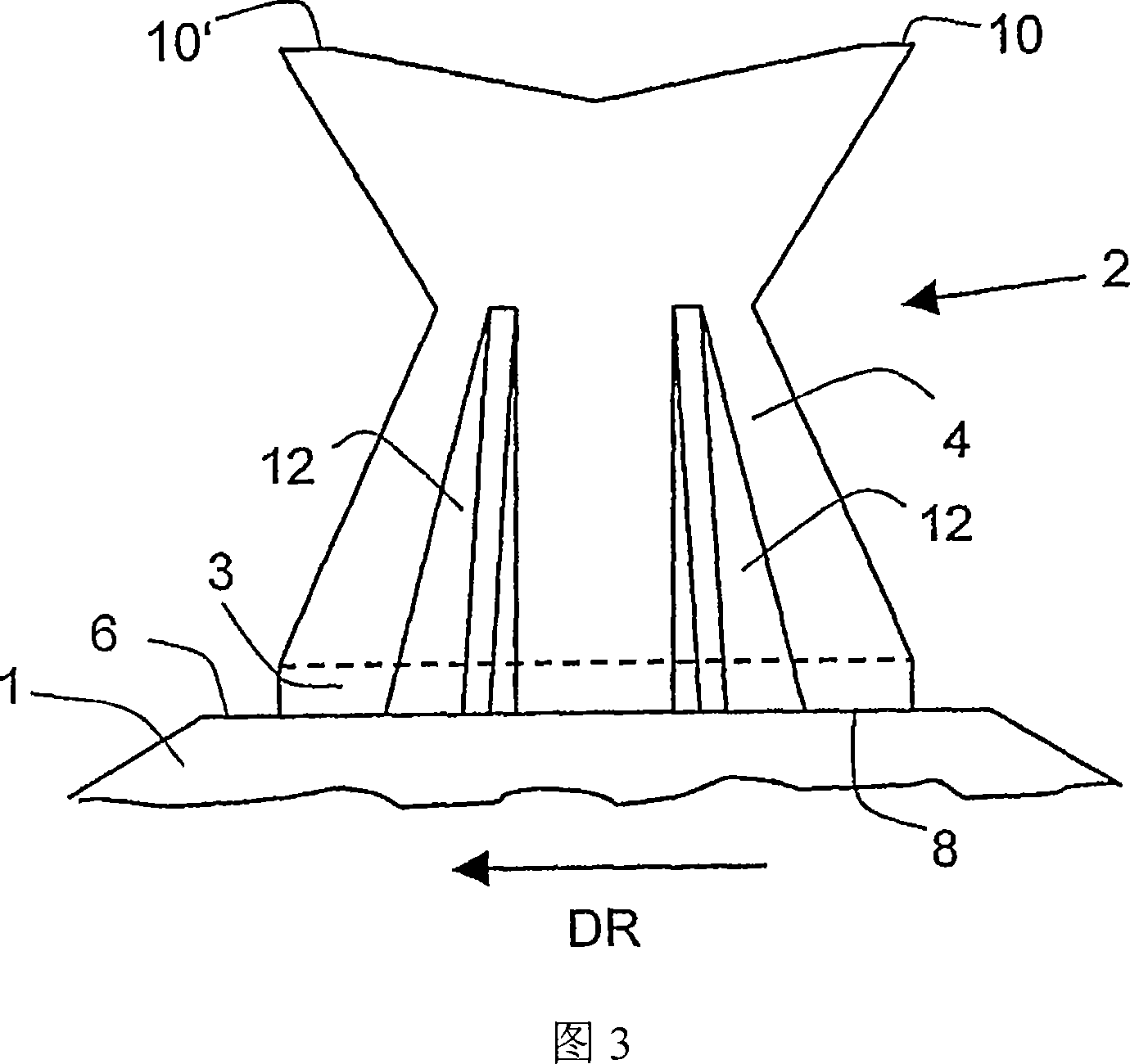

[0028] Figure 1 shows a toothed member according to the invention comprising a support 3 and teeth 4 arranged thereon. The tooth 4 has a tooth tip 10 pointing in the direction of rotation 10 and a tooth tip 10 ′ pointing in the opposite direction. The support has a flat underside and can therefore match the dodecagonal circumferential contour 6 of the removal roller 1 . FIG. 1 shows only one side of the roller 1 . In total, the roller 1 has a plurality of toothed elements 2 which are arranged on each side and are radially offset. However, since other toothed members have the same structure as the toothed member 2, only the toothed member 2 will be described in this specification. The transverse struts 5 and 5 ′ are arranged between the lateral flank socket 7 of the tooth and the upper side of the support 9 . The central transverse strut extends in the edge region between side 9 and side 7 , which forms a wedge shape. Its height extends approximately over a quarter of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com