a cotton opener

A cotton opener and cotton ball technology, which is applied in the directions of bale opening machine, fiber opening, and tooth tool opening, etc., can solve the problems of inconvenient cleaning of cotton seeds and dust, low cotton bale processing efficiency, etc., to improve the processing efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

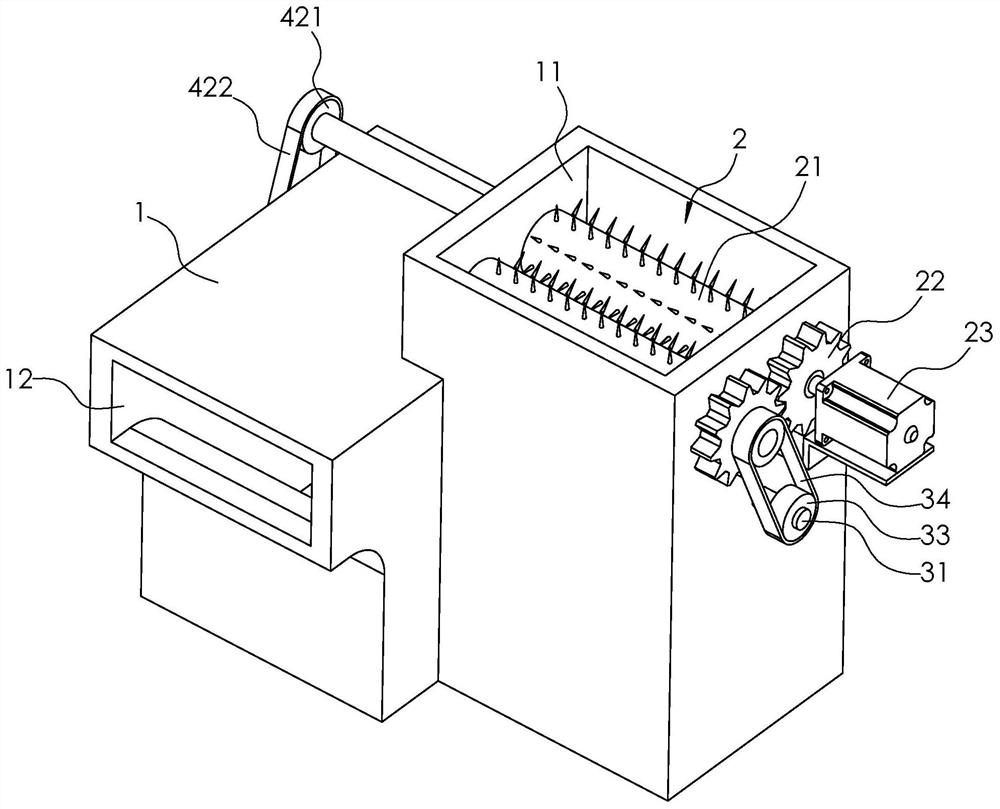

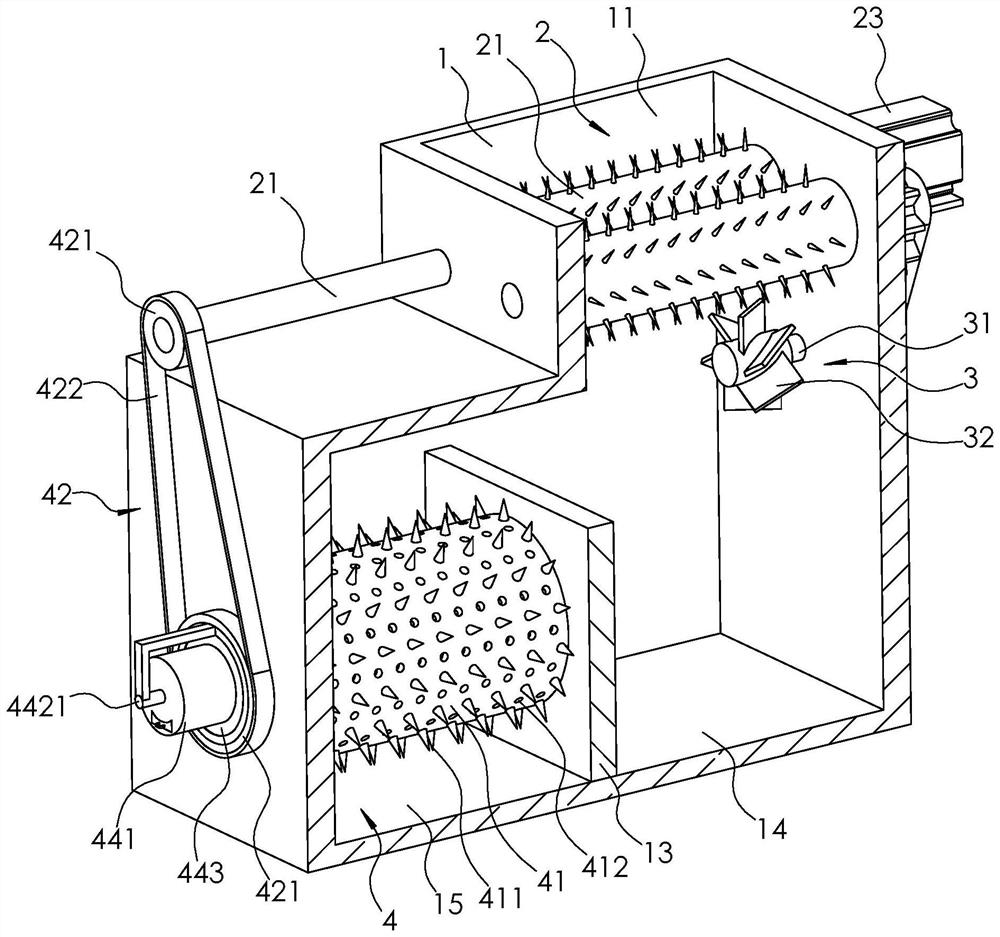

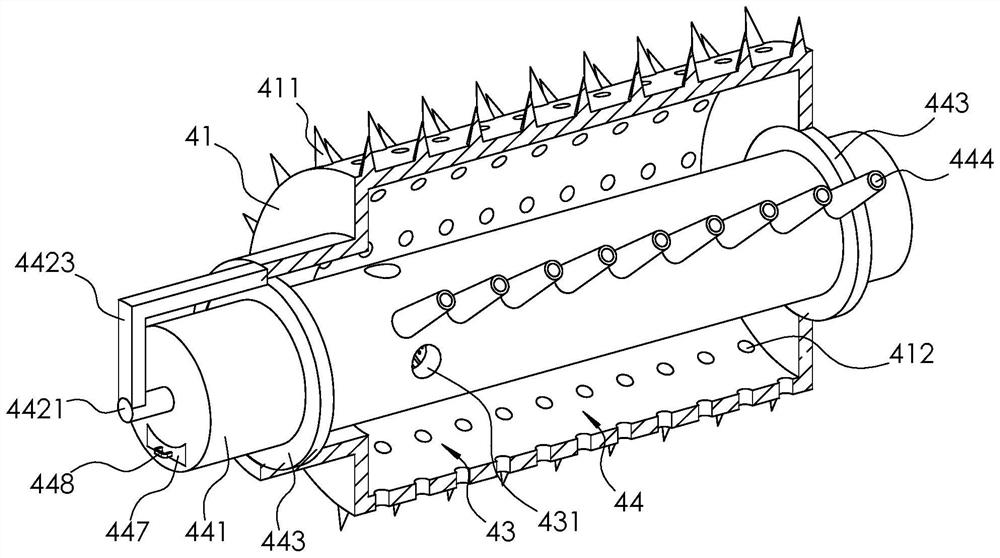

[0037] The following is attached Figure 1-5 The application is described in further detail.

[0038] The embodiment of the application discloses a cotton opener. Such as figure 1 and figure 2 As shown, a cotton opener includes a housing 1 having a material inlet 11 and a material outlet 12, and the housing 1 is provided with a crushing mechanism 2, a blowing mechanism 3 and a dust removal mechanism 4 sequentially arranged from top to bottom. The crushing mechanism 2 is used to break the cotton bales entering from the feed port 11 into small cotton balls, the blowing mechanism 3 is used to separate the small cotton balls from the cottonseed, and the dust removal mechanism 4 is used to separate the small cotton balls from dust and make the small cotton balls The cotton ball is discharged from the discharge port 12.

[0039] The feeding port 11 is located at the top of the housing 1 . The crushing mechanism 2 is located directly below the feeding port 11. The crushing mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com