Extraction roller

A technology for fastening elements, bases, applied in the field of pick-up rollers, which can solve problems such as wear marks that cannot be easily handled, impossible to replace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

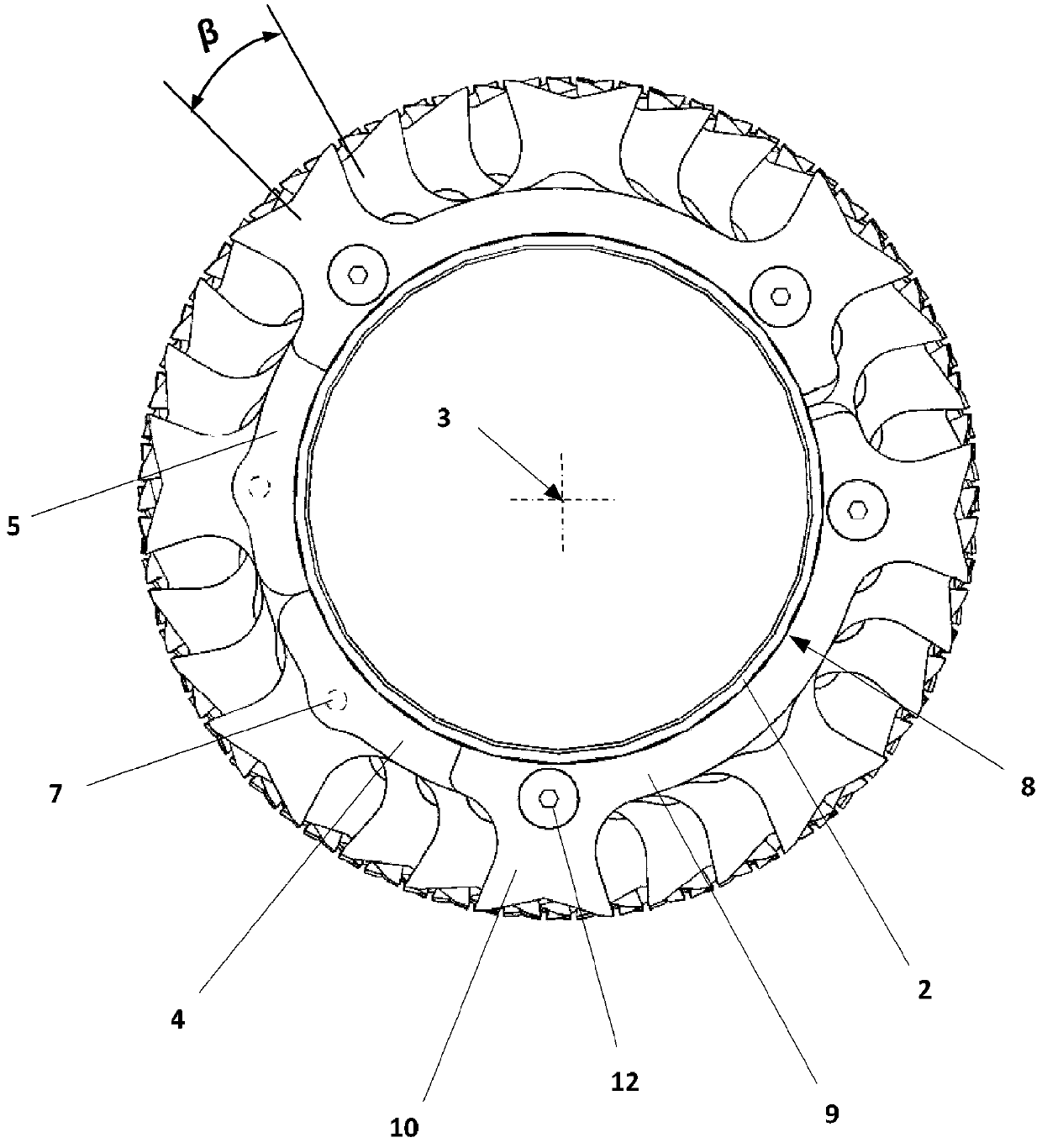

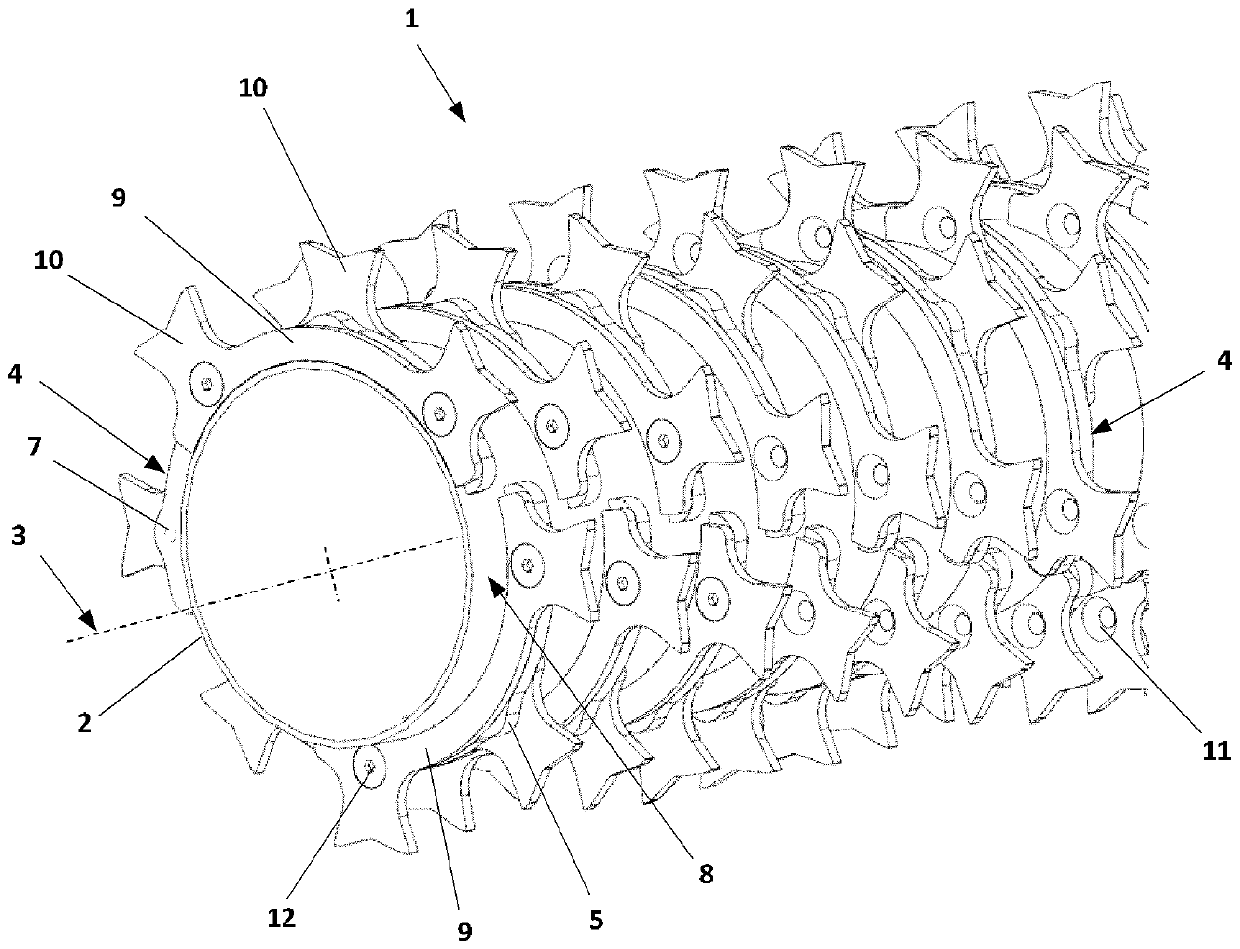

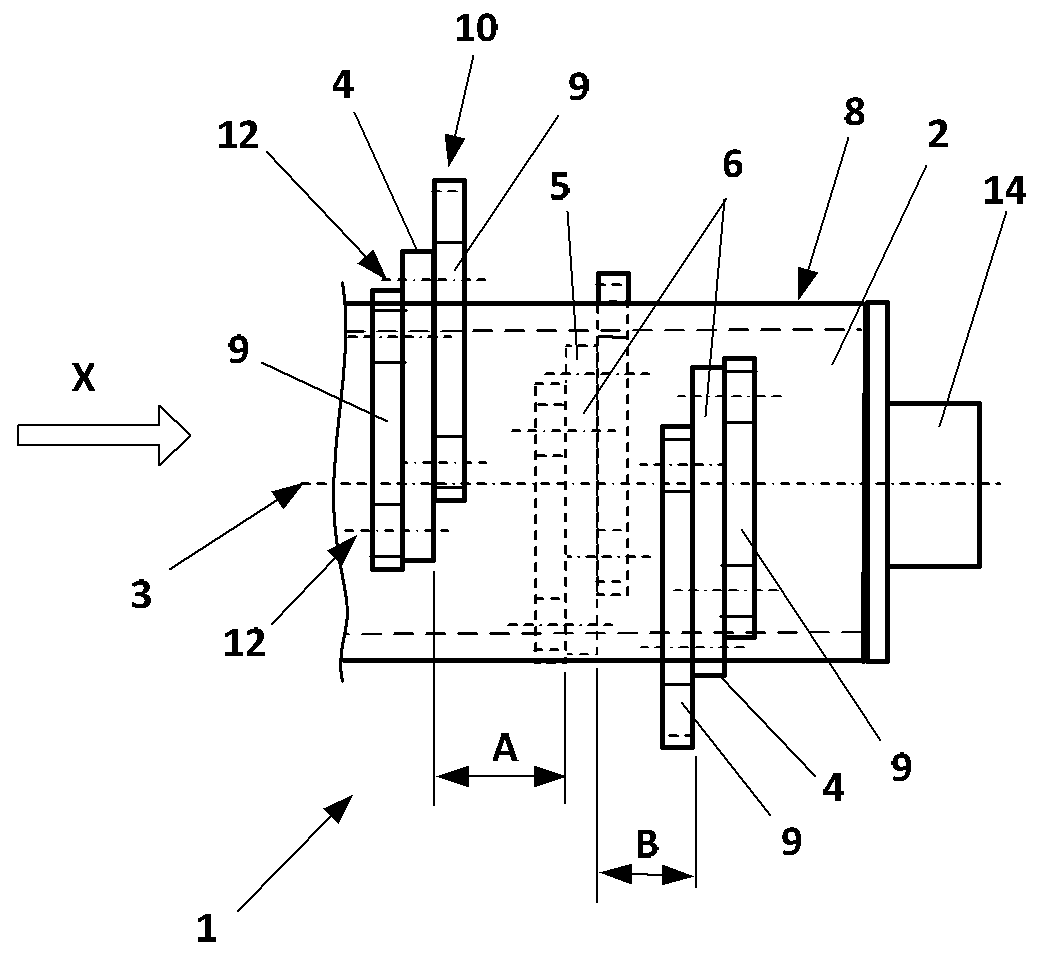

[0029] figure 1 A schematic perspective representation of the extraction roller 1 is shown. The extraction roll 1 has a roll axis 3 and comprises a base body 2 on a surface 8 of which a series of a plurality of first fastening elements 4 and second fastening elements 5 is arranged in one plane and in in concentric adjacent planes. Two sets of toothed elements 9 are respectively mounted on the fastening elements 4 and 5 via screws 12 , wherein the screws 12 engage in through-openings 11 formed in the toothed elements 9 and via through-openings 7 designed as female threads in the fastening elements 4 and 5 . fastening element 4 or 5. Two sets of tooth elements 9 are mounted on the fastening elements 4 and 5, respectively. Each tooth element 9 is equipped with two teeth 10 . The fastening elements 4 and 5 and thus also the tooth elements 9 are arranged in a sequentially offset manner in the direction of the roller axis 3 in the circumferential direction. Since all tooth elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com