Full-automatic counting board-turning stack aligner

A fully automatic, flipping technology, applied in the direction of flipping objects, stacking receiving devices, special packaging objects, etc., can solve the problems that restrict the long-term development of corrugated cardboard manufacturers, uneven dry and humidity of cardboard, and high labor costs, and achieve market potential. Huge, uniform drying and humidity up and down, reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

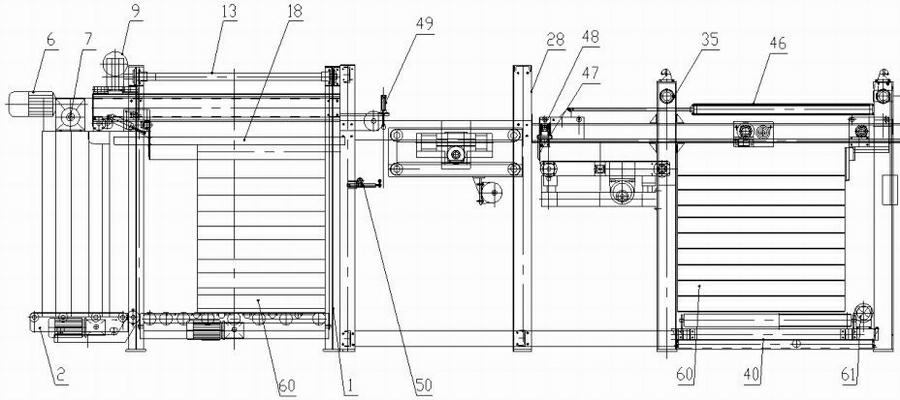

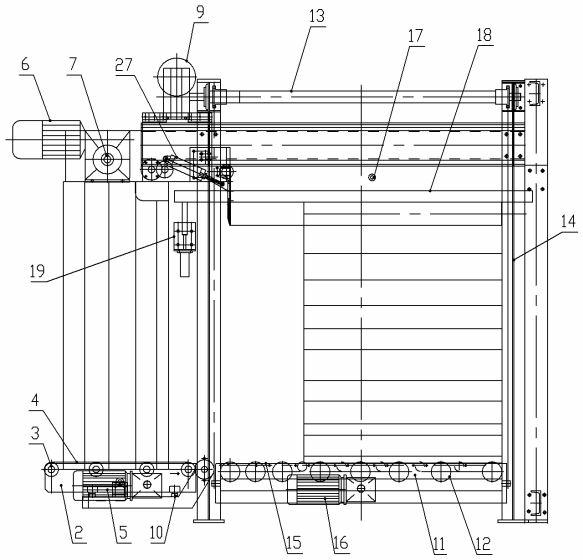

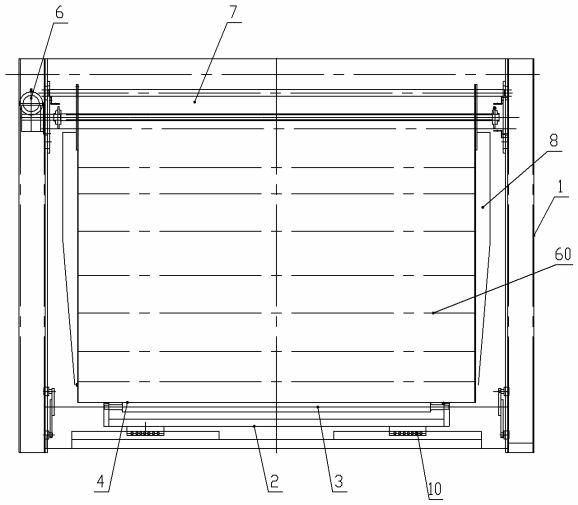

[0035] like figure 1 As shown, the fully automatic counting turnover stacker of the present invention includes a sorting and counting conveying system, a turnover system and a rear conveying stacking and sorting system, the output end of the sorting and counting conveying system is connected with the input end of the turnover system, and the turnover system The output end of the feeder is connected with the input end of the rear conveying and stacking system.

[0036] A packaging device is provided between the output end of the sorting and counting conveying system and the input end of the turnover system. The packing device comprises the packing cylinder 49 and the packing device 50 below which are located at the rear output end of the sorting and counting conveying system.

[0037] The sorting and counting conveying system includes the first frame 1 and the front conveying device, centering device, conveying and lifting device, platen device and paper pushing device arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com