Optimal design method for spliced and welded plate automobile door

A technology of optimization design and optimization method, applied in calculation, special data processing applications, instruments, etc., can solve problems such as time-consuming, not enough to guide the design of tailor-welded blank parts, and it is difficult to achieve the optimization of tailor-welded blank door at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

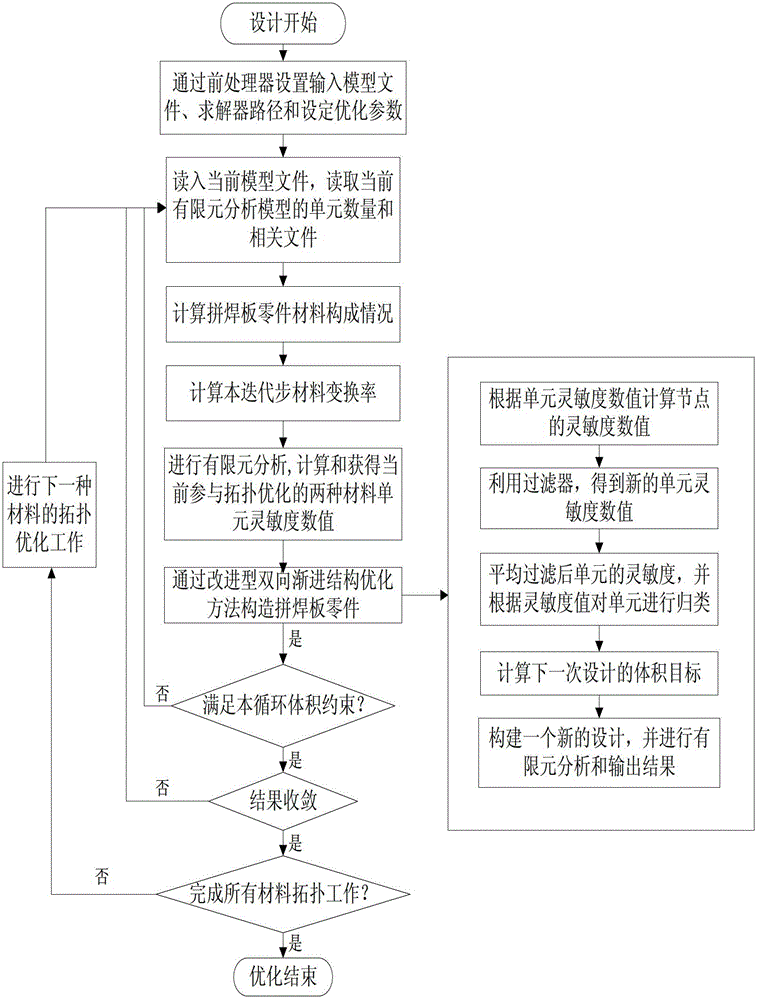

[0084] The present invention applies the two-way progressive structure optimization method, the sensitivity analysis method and the size optimization method to the design of the tailor-welded blank car door. After the specific location is determined, the sensitivity analysis method and size optimization method are used to establish a lightweight optimization model of the door system based on the response of different working conditions, and perform optimization calculations.

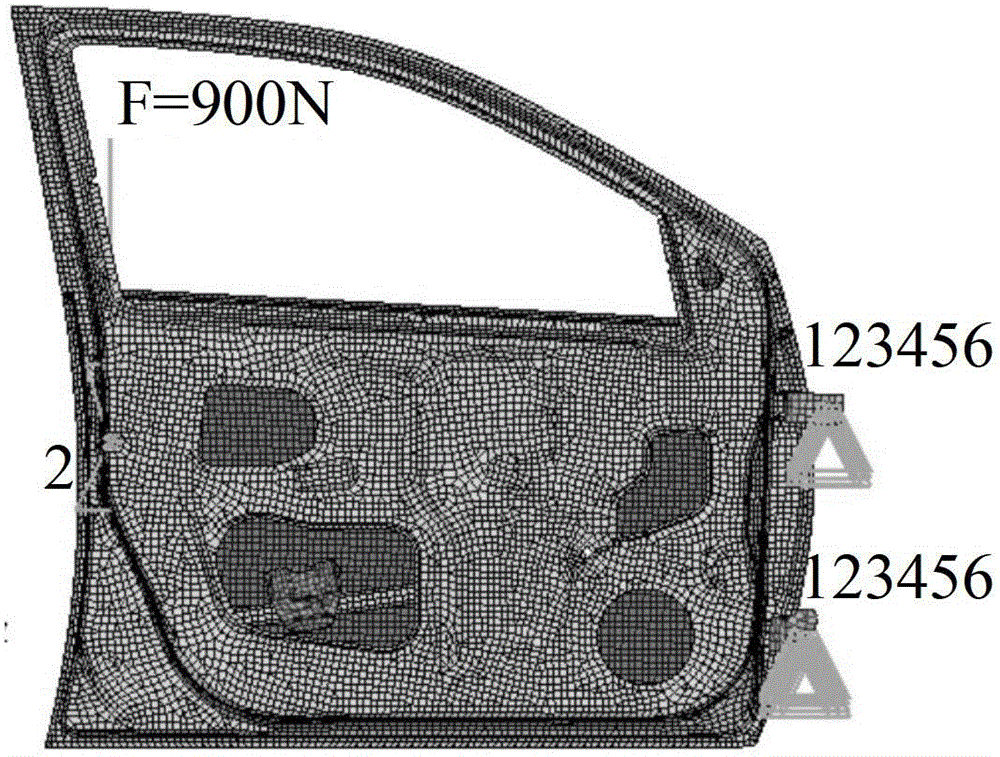

[0085] (1) Establishment of the finite element model of the door stiffness condition

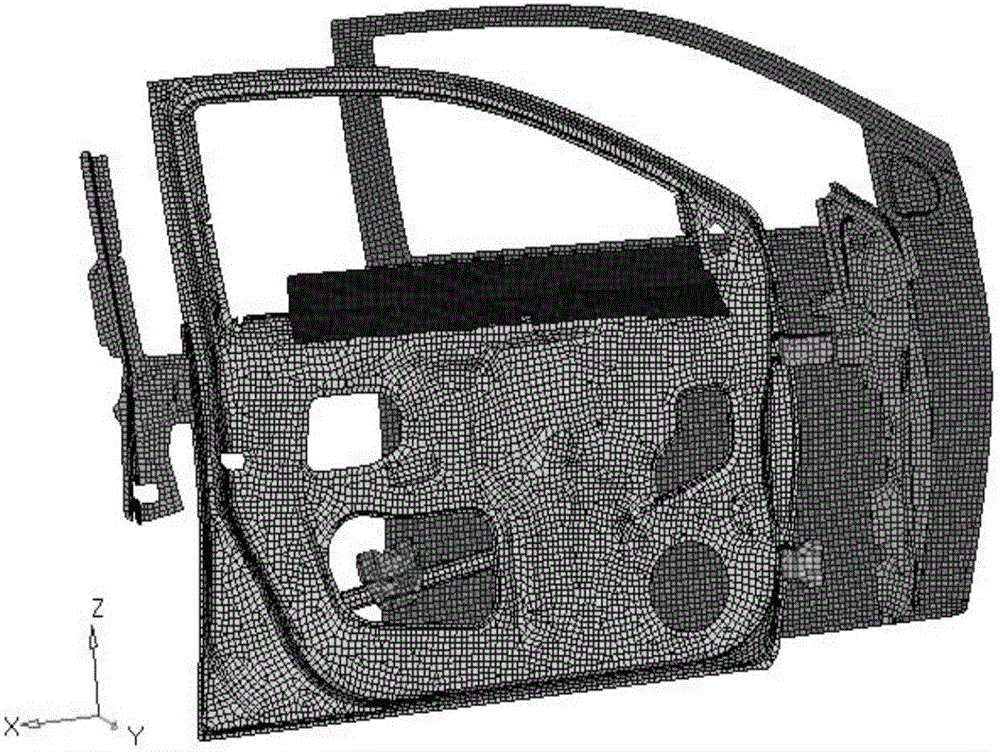

[0086] Such as figure 2 Shown is the finite element model of a typical tailor-welded blank car door studied in the embodiment of the present invention. The static stiffness of the car door is the ability of the car door to resist deformation when it is subjected to static lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com